Rare-earth-yttrium-nickel-zinc-alloy electroplating solution and preparation method thereof

A zinc alloy and electroplating solution technology, which is applied in the field of rare earth yttrium-nickel-zinc alloy electroplating solution and its preparation, can solve the problems of uneven coating, poor dispersion ability, unstable plating solution, etc., and achieve uniform distribution and stability of the coating Good, beautiful color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

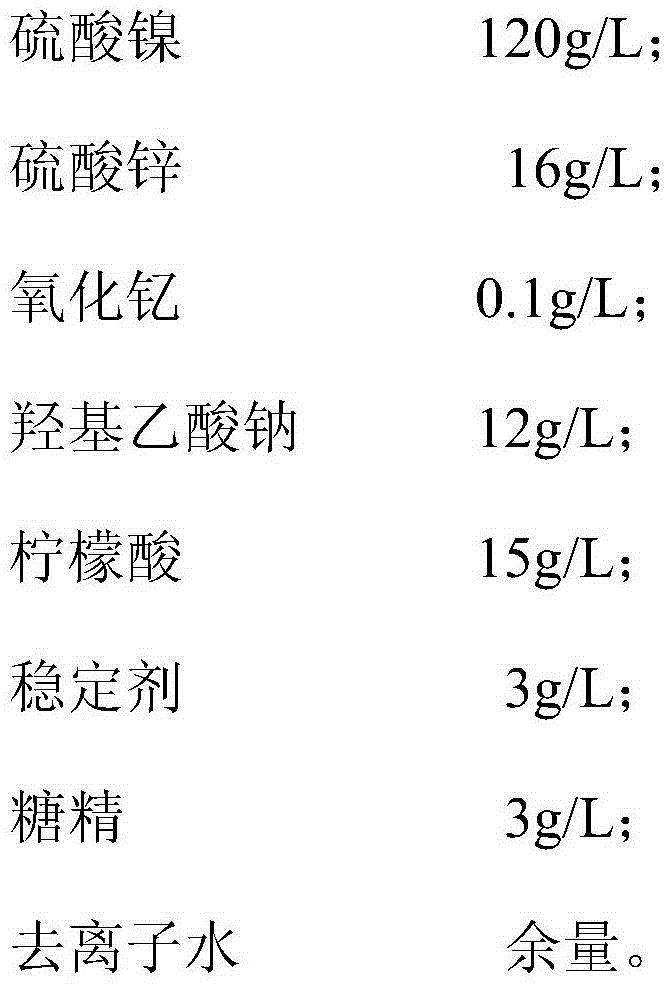

[0020] Embodiment 1: the rare earth yttrium-nickel-zinc alloy electroplating solution of the present embodiment comprises following components:

[0021]

[0022] The method for preparing this rare earth yttrium-nickel-zinc alloy electroplating solution is as follows:

[0023] Dissolve 3g of stabilizer in deionized water to form a solution, add 15g of citric acid, 16g of zinc sulfate, 12g of sodium glycolate, and 120g of nickel sulfate to the solution, stir and dissolve to form a mixed solution, and add acidified 0.1 g of yttrium oxide and 3 g of saccharin were heated to 60° C. and stirred to dissolve, then the remaining deionized water was added to make the total volume 1 L, and the pH was adjusted to 5-9 to obtain a rare earth yttrium-nickel-zinc alloy electroplating solution.

Embodiment 2

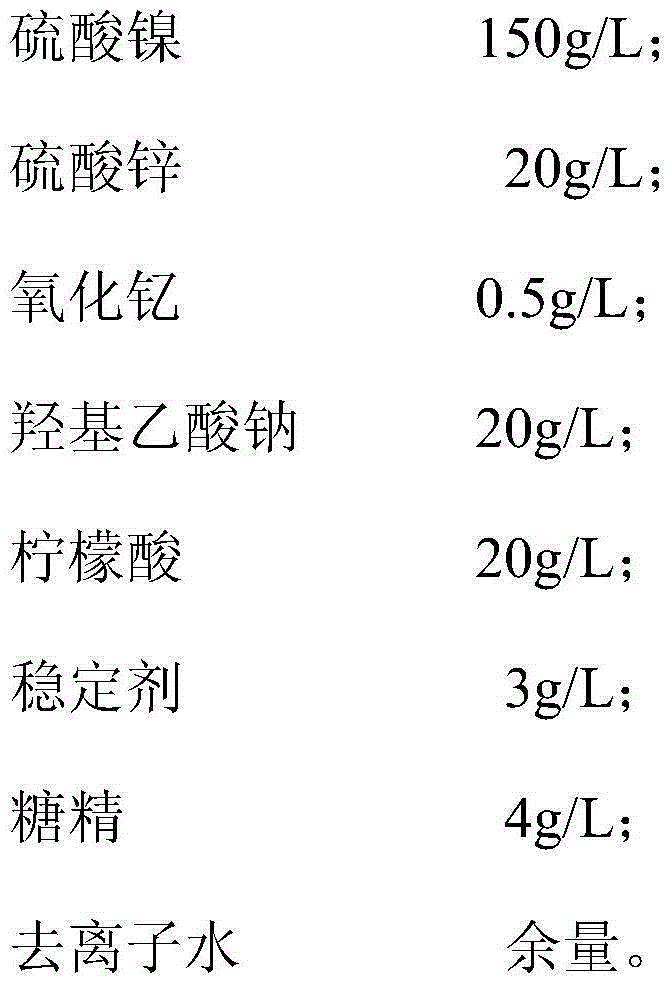

[0024] Embodiment 2: the rare earth yttrium-nickel-zinc alloy electroplating solution of the present embodiment comprises following components:

[0025]

[0026] The method for preparing this rare earth yttrium-nickel-zinc alloy electroplating solution is as follows:

[0027] Dissolve 3g of stabilizer in deionized water to form a solution, add 20g of citric acid, 20g of zinc sulfate, 20g of sodium glycolate, and 150g of nickel sulfate to the solution, stir and dissolve to form a mixed solution, and add acidified 0.5 g of yttrium oxide and 4 g of saccharin were heated to 60° C. and stirred to dissolve, then the remaining deionized water was added to make the total volume 1 L, and the pH was adjusted to 5 to 9 to obtain a rare earth yttrium-nickel-zinc alloy electroplating solution.

Embodiment 3

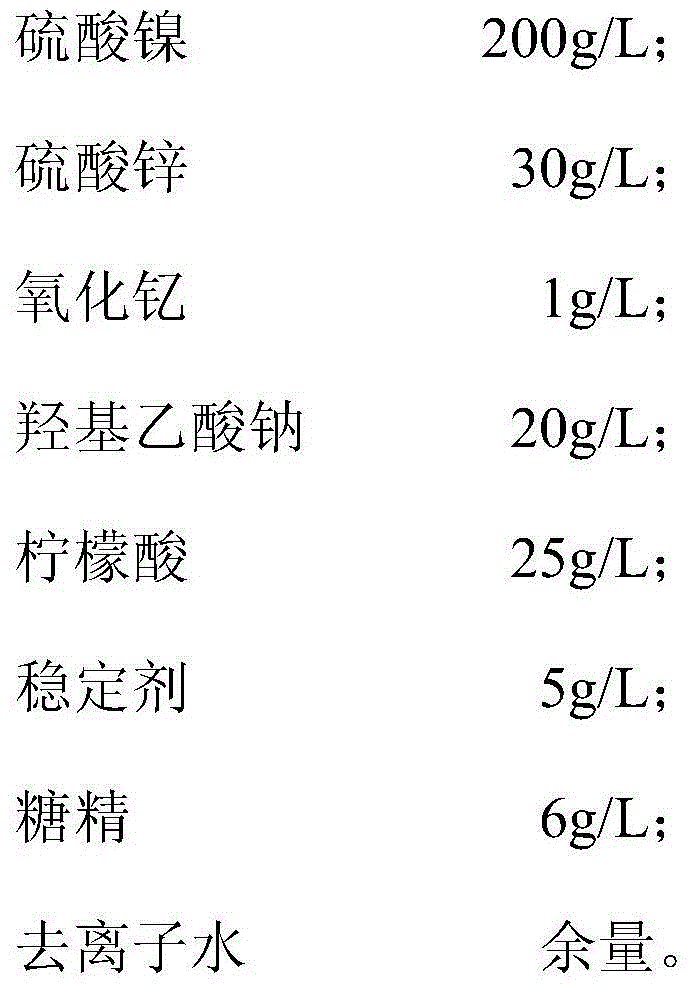

[0028] Embodiment 3: the rare earth yttrium-nickel-zinc alloy electroplating solution of the present embodiment comprises the following components:

[0029]

[0030] The method for preparing this rare earth yttrium-nickel-zinc alloy electroplating solution is as follows:

[0031] Dissolve 3g of stabilizer in deionized water to form a solution, add 25g of citric acid, 30g of zinc sulfate, 20g of sodium glycolate, and 200g of nickel sulfate to the solution, stir and dissolve to form a mixed solution, and add acidified 1g of yttrium oxide and 6g of saccharin were heated to 60°C and stirred to dissolve, then the remaining deionized water was added to make the total volume 1L, and the pH was adjusted to 5-9 to obtain a rare earth yttrium-nickel-zinc alloy electroplating solution.

[0032] The rare earth yttrium-nickel-zinc alloy electroplating solution obtained in Examples 1 to 3 has good stability during use and storage; the rare earth yttrium-nickel-zinc alloy electroplating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com