Sulfur-containing antibacterial fiber material and preparation method thereof

An antibacterial fiber and fiber material technology, which is applied in the field of sulfur-containing antibacterial fiber material and its preparation, can solve the problems of poor slow release, easy volatility, and spinning broken, and achieves simple preparation process, reduced side effects, and mildew resistance. insect repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A sulfur-containing antibacterial fiber material, the composition of which is calculated by mass percentage: 80% of fiber matrix material, 5% of sulfur, and 15% of slow-release auxiliary agent, wherein the fiber matrix material is polypropylene, and the sulfur is settled sulfur. The additive is prepared by mixing polypropylene, precipitated sulfur, dicumyl peroxide, and diphenylguanidine at a mass ratio of 85%, 13%, 1%, and 1%, and then plasticizing at 200-240°C. made.

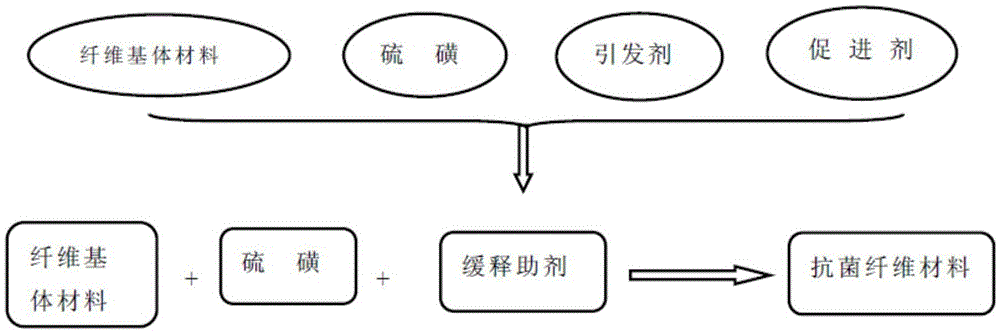

[0032] The principle of its preparation method is as follows figure 1 shown, including the following steps:

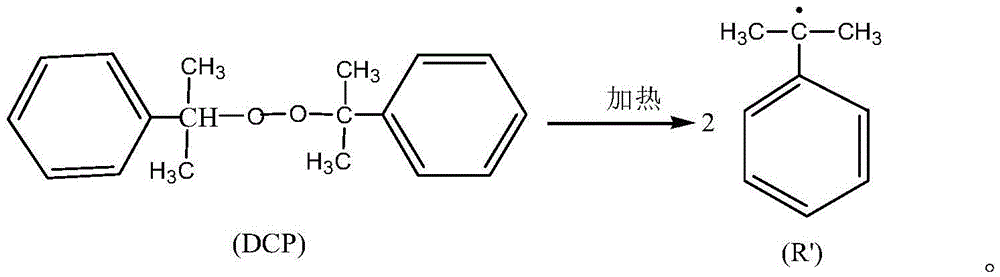

[0033] 1) Weighing raw materials: according to the mass ratio of 85% polypropylene, 13% sedimentation sulfur and 1% diphenylguanidine, 1% dicumyl peroxide;

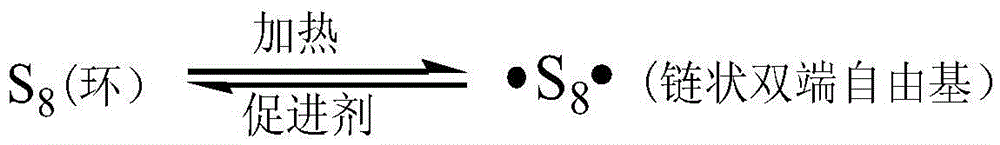

[0034] 2) Preparation of sustained-release aids: Stir and mix the weighed polypropylene, precipitated sulfur, diphenylguanidine and dicumyl peroxide evenly, and then masticate on an internal mixer at a temperature of 200°C. Refining for ...

Embodiment 1

[0036] Gained sulfur-containing antibacterial fiber material performance test of embodiment 1:

[0037] The antibacterial performance test refers to GB / T31713-2015 (safety and hygiene requirements for antibacterial textiles) and QB / T2591-2003 (antibacterial plastics - antibacterial performance test methods and antibacterial effect standards). In this method, the sulfur-containing antibacterial fiber to be tested is first made into a non-woven fabric sample with a thickness of about 0.5 mm, placed in a petri dish, and then the suspensions of Staphylococcus aureus and Escherichia coli are quantitatively inoculated on the sample to be tested, and the sample is covered with a film. The method is to make the bacterial suspension evenly contact the sample, after 24 hours of constant temperature and humidity culture, measure the number of viable bacteria in the sample, and calculate the antibacterial rate of the sample.

[0038]

[0039] Test results: the antibacterial rate of the...

Embodiment 2

[0041] A sulfur-containing antibacterial fiber material, the composition of which is calculated by mass percentage: 80% of fiber matrix material, 5% of sulfur, and 15% of slow-release auxiliary agent, wherein the fiber matrix material is polypropylene, and the sulfur is sublimated sulfur. The additive is prepared by mixing polypropylene, sublimed sulfur, benzoyl peroxide, and diphenylguanidine at a mass ratio of 90%, 9%, 0.5%, and 0.5%, and then plasticizing at 200-240°C. become.

[0042] Its preparation method comprises the following steps:

[0043] 1) Weigh raw materials: 90% polypropylene, 9% sublimated sulfur, 0.5% diphenylguanidine, and 0.5% benzoyl peroxide according to the mass ratio;

[0044] 2) Preparation of sustained-release additives: Stir and mix the weighed polypropylene, sublimed sulfur, diphenylguanidine and benzoyl peroxide evenly, and then masticate on an internal mixer at a temperature of 220°C. 4h, the obtained solid is sustained-release aid: grafted vulc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com