Multi-function printing thickener and preparation method thereof

A thickener and multi-functional technology, applied in the field of textile printing, can solve the problems of high dosage and high cost of sodium alginate, and achieve the effect of improving hand feeling, increasing coloring amount, and remarkable thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

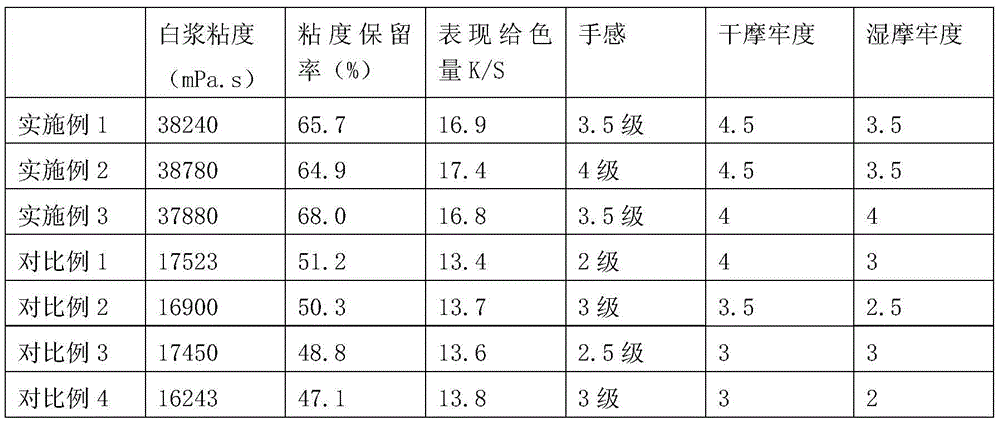

Examples

Embodiment 1

[0027] Multifunctional printing thickener, comprising the following components by weight: 5 parts of tributyl phosphate; 12 parts of polyacrylate; 2 parts of fatty alcohol polyoxyethylene ether; 3 parts of betaine; 3 parts of etherified guar gum ; 4 parts of methylenebisacrylamide; 0.3 parts of sorbitan glyceride; 1 part of initiator; 0.5 parts of soft oil; 2 parts of N-methylolacrylamide; 20 parts of deionized water.

Embodiment 2

[0029] Multifunctional printing thickener, comprising the following components in parts by weight: 10 parts of tributyl phosphate; 28 parts of polyacrylate; 9 parts of fatty alcohol polyoxyethylene ether; 10 parts of betaine; 10 parts of etherified guar gum ; 18 parts of methylenebisacrylamide; 6 parts of sorbitan glyceride; 3 parts of initiator; 5 parts of soft oil; 15 parts of N-methylol acrylamide; 40 parts of deionized water.

Embodiment 3

[0031] Multifunctional printing thickener, comprising the following components by weight: 6 parts of tributyl phosphate; 18 parts of polyacrylate; 6 parts of fatty alcohol polyoxyethylene ether; 5 parts of betaine; 7 parts of etherified guar gum ; 9 parts of methylenebisacrylamide; 2 parts of sorbitan glyceride; 2 parts of initiator; 4 parts of soft oil; 3 parts of N-methylolacrylamide; 30 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com