Inclination measurement hole construction method

A construction method and technology of measuring inclination holes, which are applied in the directions of surveying, earthwork drilling, boreholes/well components, etc., can solve the problems of small gaps, large data errors, insufficient backfill compaction, etc., and achieve volume reduction and reduction Effect of small shotcrete pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

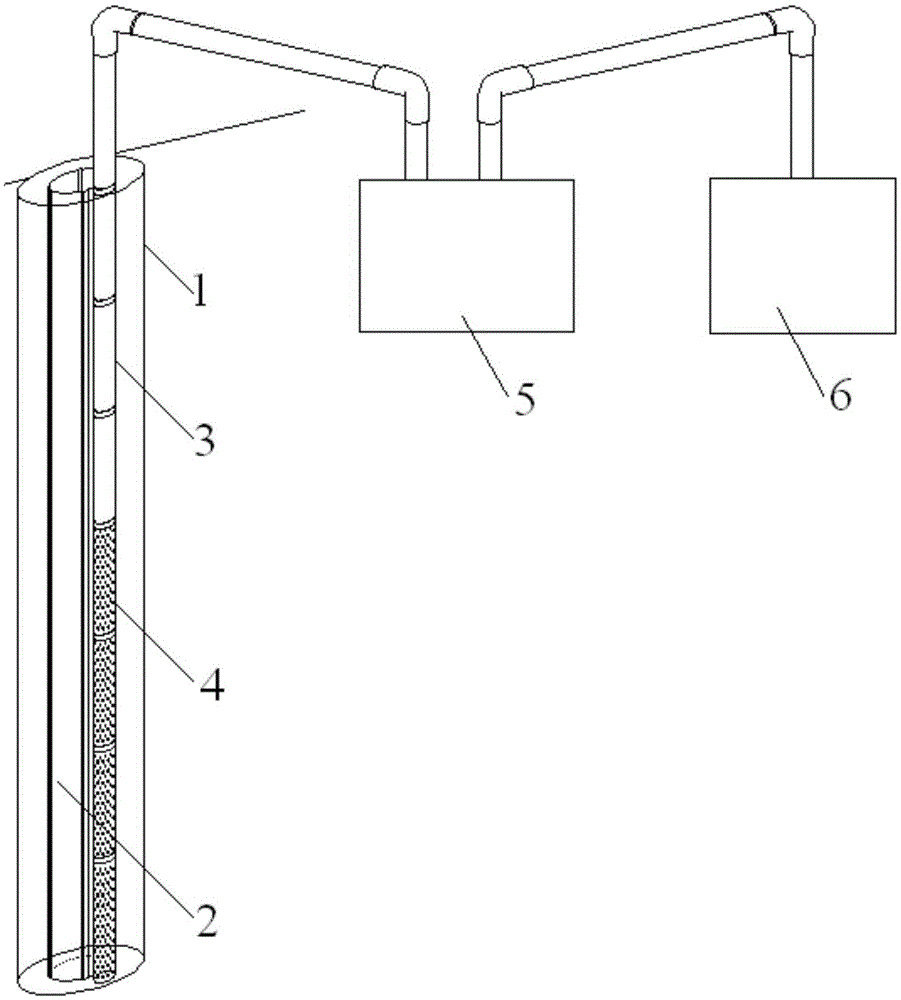

[0030] The construction method of the inclinometer hole provided by the invention, its construction principle is as follows: figure 1 shown, including the following steps:

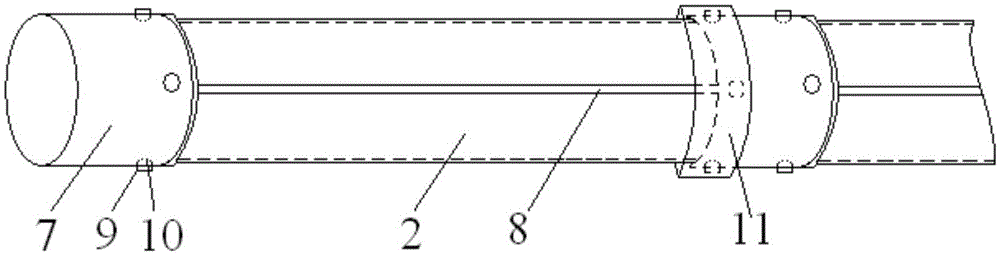

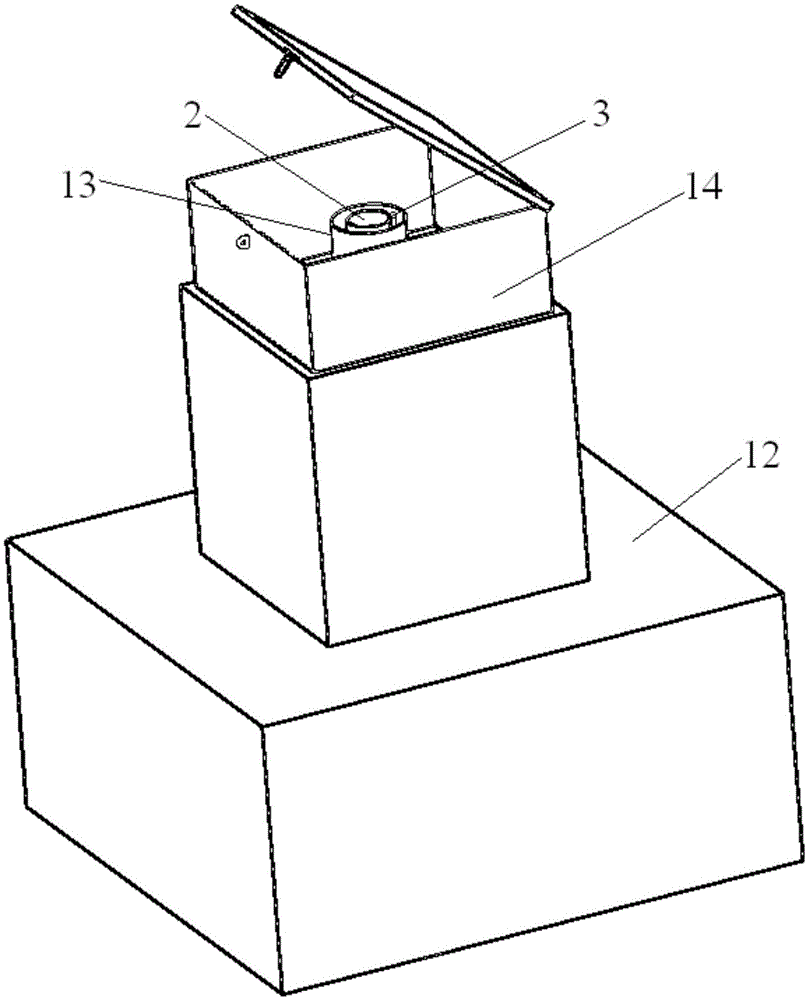

[0031] (1) Drill into the inclinometer borehole 1. After the drilling is completed, inject clean water into the inclinometer borehole at a constant speed through the drill pipe to wash the hole, and inject water until clear water overflows from the inclination borehole hole, and the hole washing is completed; More than two inclinometer tubes 2 with guide grooves 8 on the surface are lowered into the inclinometer borehole in turn, two adjacent inclinometer tubes are connected by sleeves 7 and anchored by rivets 10, and the inclinometer tubes and sleeves are connected by electric drills. Drill a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com