System and method for accelerated water tree aging of 10kv XLPE cables

A cross-linked polyethylene and cable technology, which is applied in the direction of applying a stable bending force to test the strength of materials, measure electricity, and measure electrical variables. It can solve problems such as the aggravation of thermal aging, mechanical aging of cables, and the impact of safe use of cables. Achieve good sealing performance and avoid integrity damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

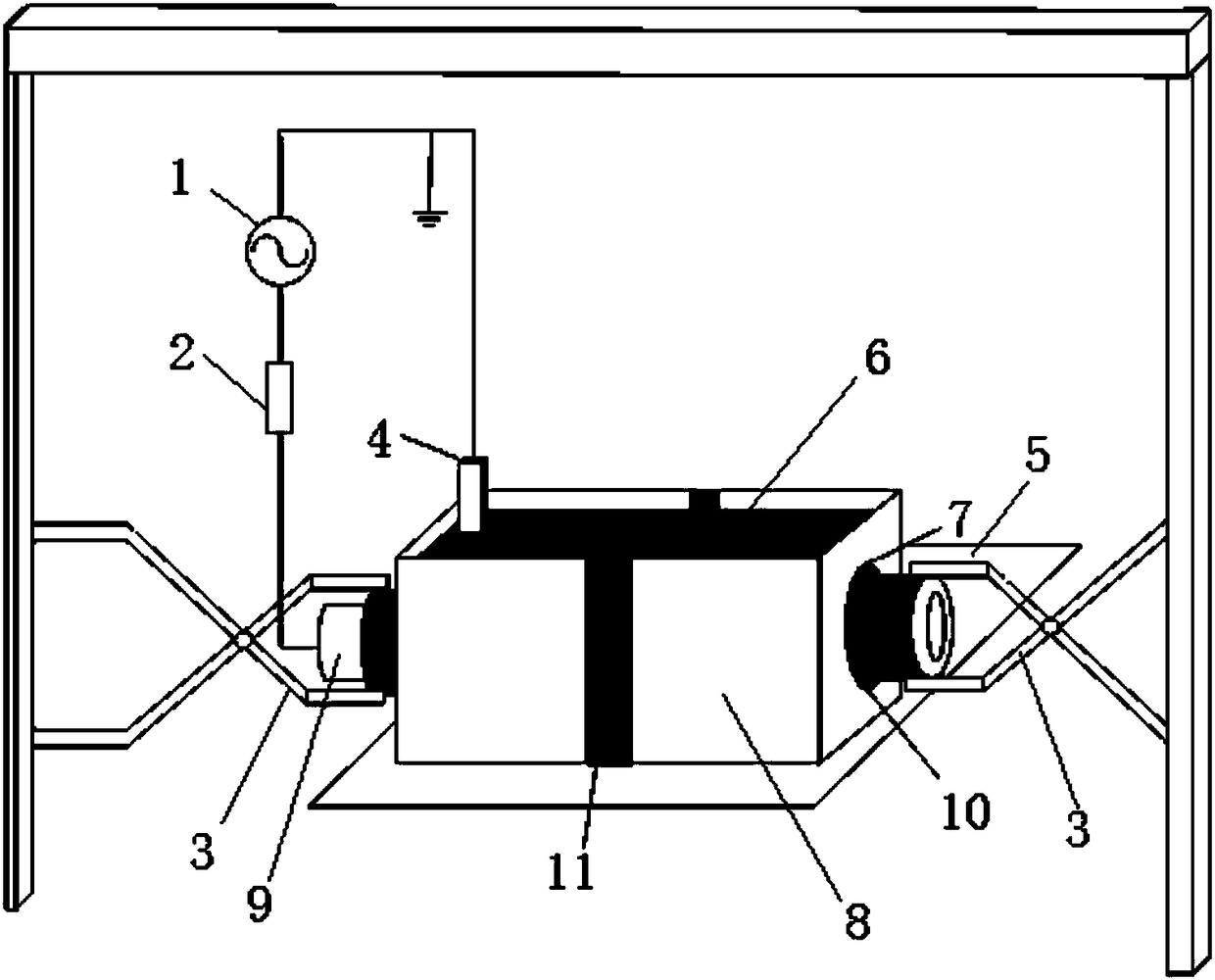

[0025] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

[0026] figure 1 Shown is a schematic structural diagram of the system for accelerated water tree aging of 10kV cross-linked polyethylene cable samples according to the present invention. Wherein the epoxy resin box body 8 is provided with a sealing hole 10 on both sides facing to each other, and the size of the sealing hole 10 is according to the XLPE cable (such as figure 1 The size design of the single-phase sample section of the cable 9) is designed, and at the same time, two sealing rings 7 are arranged at the sealing hole 10, so as to prevent the liquid in the epoxy resin box 8 from leaking. The epoxy resin box body 8 is made of epoxy resin, which has the characteristics of high temperature resistance. If it is made of ceramics, it will be brittle, and if it is made of metal, it will be prone to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com