Fiber interlayer transformer iron core and stacking method thereof

A technology of transformers and interlayers, applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, electrical components, etc., can solve the problems of electromagnetic vibration noise of iron core, intensified bending vibration of iron core, increase of radiation noise, etc. Insulating properties, reducing interlayer friction, reducing wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the drawings.

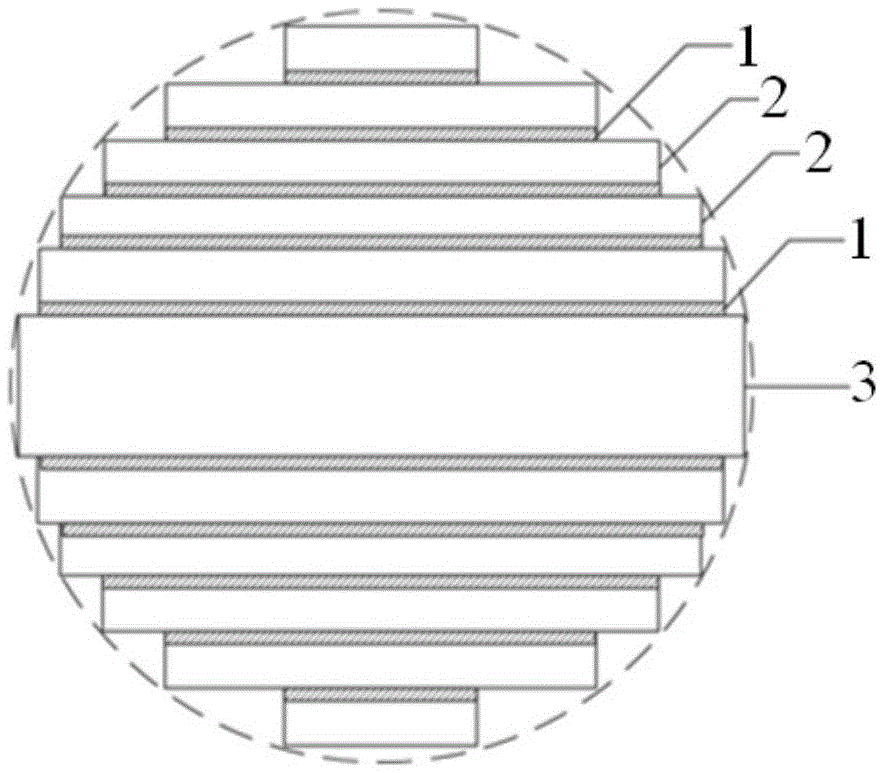

[0033] See figure 1 , A fiber sandwich transformer core, usually there are 5 levels on both sides of the main stage 3, each level contains a number of silicon steel sheet laminates 2, and a fiber interlayer 1 is arranged between adjacent silicon steel sheet laminates 2.

[0034] The thickness of the fiber interlayer 1 is 0.3 mm, 0.38 mm or 0.5 mm; the material of the fiber interlayer 1 is nylon, nylon, glass fiber, etc., and the mesh size of nylon, nylon, and glass fiber is 30 mesh to 60 mesh.

[0035] The thickness of the fiber interlayer is 1 to 1.2 times the thickness of the silicon steel sheet.

[0036] The grain direction of the fiber interlayer is 45 degrees with the rolling direction of the silicon steel sheet.

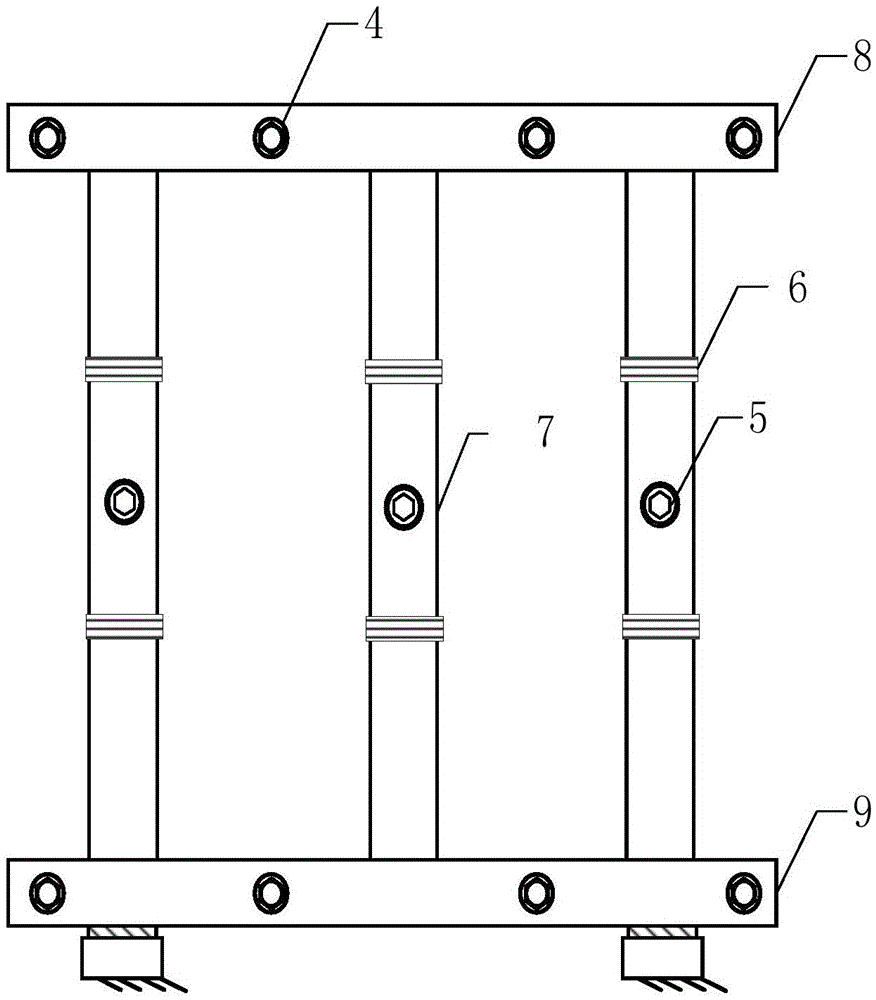

[0037] See figure 2 , A method for stacking fiber sandwich transformer cores, through the stacking process of silicon steel sheets, a fiber sandwich is arranged between ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com