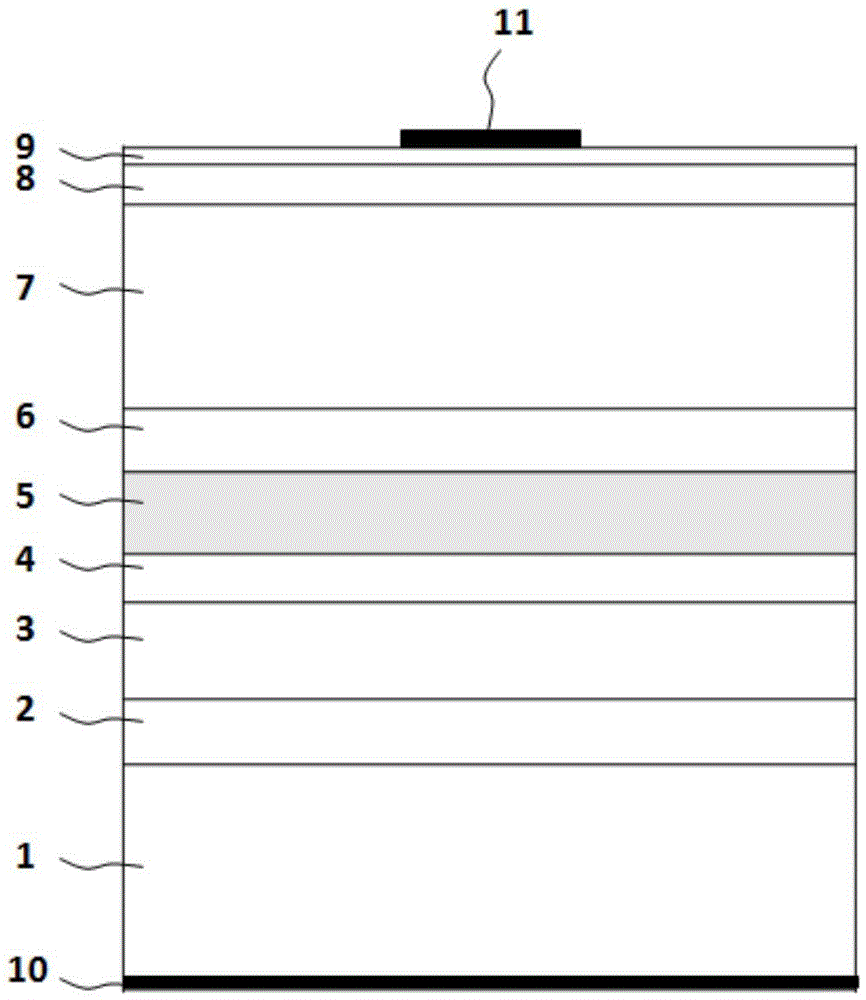

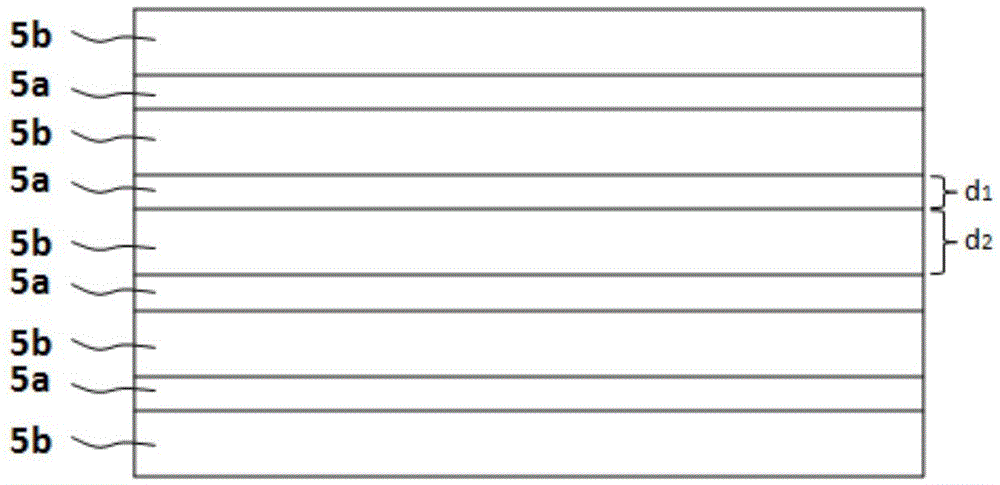

Infrared light-emitting diode with strain harmony multi-quantum well structure

A multi-quantum well structure and infrared light-emitting technology, applied in the field of infrared light-emitting diodes, can solve problems such as difficulty in making monochromatic multi-quantum well structures and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The contact layer is a P-type contact layer Al heavily doped with C X Ga 1-X As, where X is 35% and the concentration is 8E18 atoms / cm.

[0027] The P-type first cladding layer is a C-doped P-type first cladding layer Al X Ga 1-X As, wherein X is 15%, and the concentration is 8E17 atoms / cm; the P-type second cladding layer is a C-doped P-type second cladding layer Al X Ga 1-X As, where X is 35% and the concentration is 1E18 atoms / cm.

[0028] The N-type second cladding layer is an N-type second cladding layer Al doped with Si X Ga 1-X As, wherein X is 35%, and the concentration is 1E18 atoms / cm; the N-type first cladding layer is an N-type first cladding layer Al doped with Si X Ga 1-X As, where X is 15%, and the concentration is 6E17 atoms / cm.

[0029] The buffer layer is a buffer layer composed of GaAs, and the concentration is 1.5E18 atoms / cm.

[0030] The GaAs substrate is a single crystal N-type GaAs substrate doped with Si, and the concentration is 1.2E1...

Embodiment 2

[0035] The contact layer is a P-type contact layer Al heavily doped with C X Ga 1-X As, where X is 35% and the concentration is 8E18 atoms / cm.

[0036] The P-type first cladding layer is a C-doped P-type first cladding layer Al X Ga 1-X As, wherein X is 15%, and the concentration is 8E17 atoms / cm; the P-type second cladding layer is a C-doped P-type second cladding layer Al X Ga 1-X As, where X is 35% and the concentration is 1E18 atoms / cm.

[0037] The N-type second cladding layer is an N-type second cladding layer Al doped with Si X Ga 1-X As, wherein X is 35%, and the concentration is 1E18 atoms / cm; the N-type first cladding layer is an N-type first cladding layer Al doped with SiX Ga 1-X As, where X is 15%, and the concentration is 6E17 atoms / cm.

[0038] The buffer layer is a buffer layer composed of GaAs, and the concentration is 1.5E18 atoms / cm.

[0039] The GaAs substrate is a single crystal N-type GaAs substrate doped with Si, and the concentration is 1.2E18 ...

Embodiment 3

[0043] The contact layer is a P-type contact layer Al heavily doped with C X Ga 1-X As, where X is 35% and the concentration is 8E18 atoms / cm.

[0044] The P-type first cladding layer is a C-doped P-type first cladding layer Al X Ga 1-X As, wherein X is 15%, and the concentration is 8E17 atoms / cm; the P-type second cladding layer is a C-doped P-type second cladding layer Al X Ga 1-X As, where X is 35% and the concentration is 1E18 atoms / cm.

[0045] The N-type second cladding layer is an N-type second cladding layer Al doped with Si X Ga 1-X As, wherein X is 35%, and the concentration is 1E18 atoms / cm; the N-type first cladding layer is an N-type first cladding layer Al doped with Si X Ga 1-X As, where X is 15%, and the concentration is 6E17 atoms / cm.

[0046] The buffer layer is a buffer layer composed of GaAs, and the concentration is 1.5E18 atoms / cm.

[0047] The GaAs substrate is a single crystal N-type GaAs substrate doped with Si, and the concentration is 1.2E1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com