Distillation kettle and operation process thereof

An operation process and distillation kettle technology, which is applied in distillation regulation/control, boiler/distillate distillation, organic chemistry, etc., can solve the problems of accelerated evaporation of impurity liquid, high operation process cost, and high distillation cost, and achieves improved purity, Improve purification efficiency and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

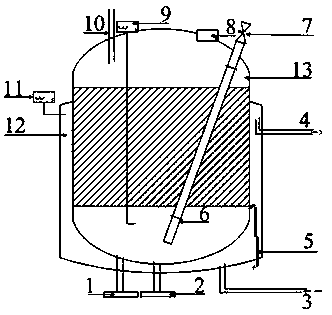

[0040] Such as figure 1 Shown, a kind of distillation kettle comprises shell 13, and housing 13 is provided with air inlet pipe 6, and one end of air inlet pipe 6 is inserted in the raw material liquid surface of still kettle, and the bottom distance with housing 13 is 10mm, and the bottom distance of housing 13 is 10mm. The other end of the empty pipe 6 is located outside the casing 13 and a control valve 7 is arranged on the pipeline of the empty pipe 6 . Here, it is further explained that the other end of the air inlet pipe 6 is located outside the housing 13 , and the other end of the air inlet pipe 6 is fixedly connected with the top wall of the housing 13 , that is, welded on the housing 13 .

[0041] The number of the air inlet pipes 6 is 2, and they are evenly and symmetrically distributed in the housing 13 with the central axis of the still still as the axis.

[0042] One end of the inlet pipe 6 near the bottom of the housing 13 is provided with an emptying hole, and...

Embodiment 2

[0050] Such as figure 1 Shown, a kind of distillation kettle comprises shell 13, and housing 13 is provided with air inlet pipe 6, and one end of air inlet pipe 6 is inserted in the raw material liquid level of still kettle, and the bottom distance with housing 13 is 200mm, and the bottom distance of housing 13 is 200mm. The other end of the empty pipe 6 is located outside the casing 13 and a control valve 7 is arranged on the pipeline of the empty pipe 6 . Here, it is further explained that the other end of the air inlet pipe 6 is located outside the housing 13 , and the other end of the air inlet pipe 6 is fixedly connected with the top wall of the housing 13 , that is, welded on the housing 13 .

[0051] The number of air inlet pipes 6 is 4, and they are evenly and symmetrically distributed in the housing 13 with the central axis of the still still as the axis.

[0052] The end of the air inlet pipe 6 near the bottom of the housing 13 is provided with an emptying hole, and...

Embodiment 3

[0060] Such as figure 1 Shown, a kind of distillation still comprises housing 13, and housing 13 is provided with air inlet pipe 6, and one end of air inlet pipe 6 is inserted in the raw material liquid surface of still kettle, and the bottom distance with housing 13 is 100mm, enters The other end of the empty pipe 6 is located outside the casing 13 and a control valve 7 is arranged on the pipeline of the empty pipe 6 . It is further explained here that the other end of the air inlet pipe 6 is located outside the housing 13, and the other end of the air inlet pipe 6 extends outside the top wall of the housing 13, and is in a plug-in flexible connection with the top wall of the housing 13.

[0061] The number of the air inlet pipes 6 is three, and they are evenly and symmetrically distributed on the housing 13 with the central axis of the still still as the axis.

[0062]One end of the inlet pipe 6 near the bottom of the housing 13 is provided with an emptying hole, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com