Liquid dehumidification combined vortex tube low-temperature air-flow output device and pulverizing system

A liquid dehumidification and output device technology, applied in the field of low-temperature crushing, can solve the problems of large power consumption, waste of cooling capacity, complex system, etc., and achieve the effects of saving energy, saving energy consumption, and reducing specific heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

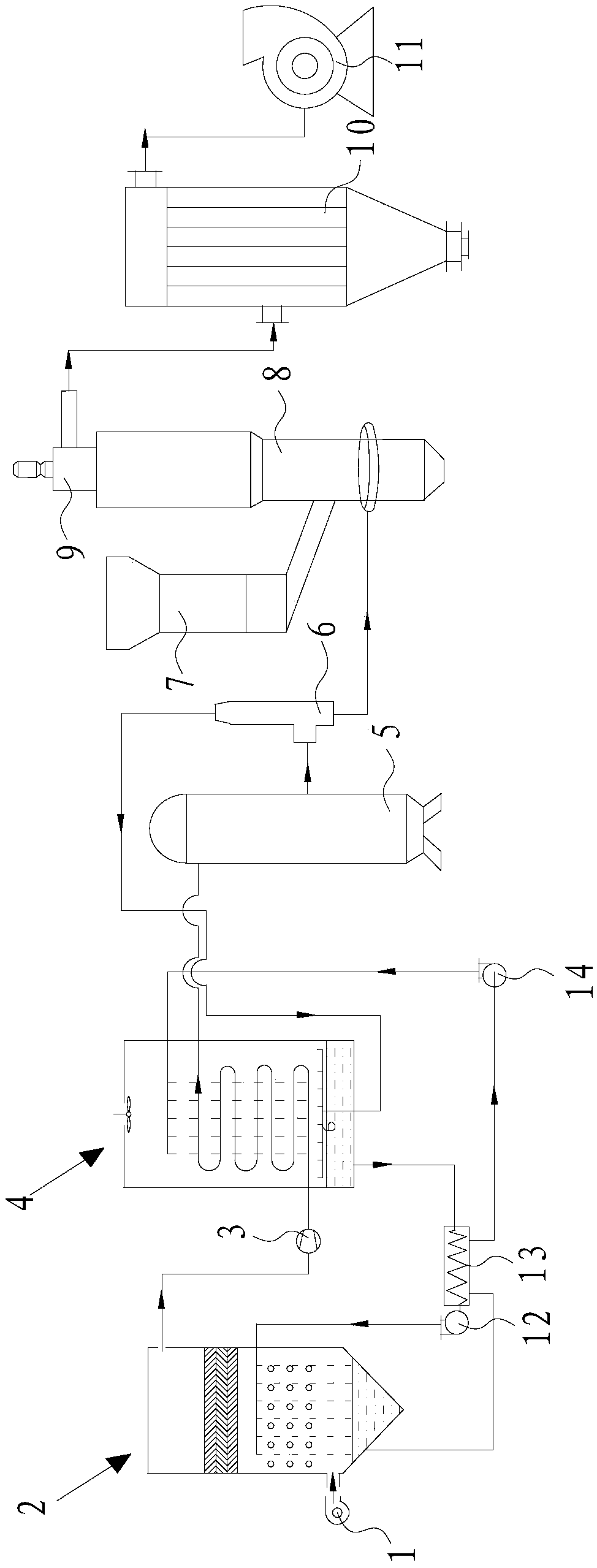

[0036] Such as figure 1 As shown, the low-temperature jet crushing system of the present embodiment includes: blower 1, drier 2, compressor 3, reducer 4, gas storage tank 5, vortex tube 6, freezer 7, fluidized bed 8, turbo separator 9. Pulse bag collector 10, induced draft fan 11, infusion pump 12, heat exchanger 13 and infusion pump 14.

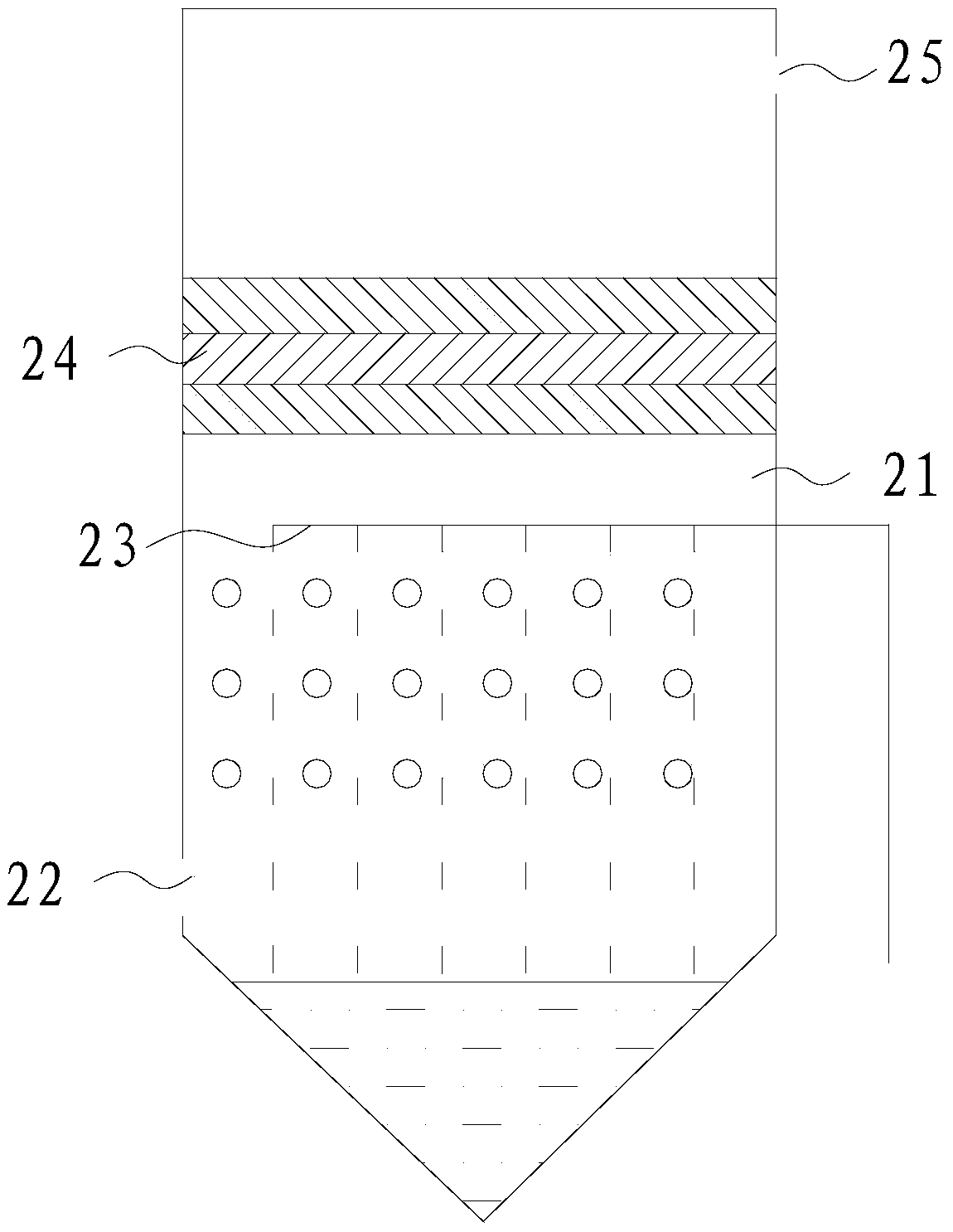

[0037] The dryer 2 includes a drying chamber 21, an air inlet 22, a first spraying unit 23, a defogging layer 24 and an air outlet 25, the air inlet 22 is arranged at the bottom of the drying chamber 21, and the first spraying unit 23 is arranged in the drying chamber 21 Inside and above the air inlet 22 , the air outlet 25 is arranged on the drying chamber 21 and above the first spraying unit 23 , and the demister layer 24 is arranged between the first spraying unit 23 and the air outlet 25 .

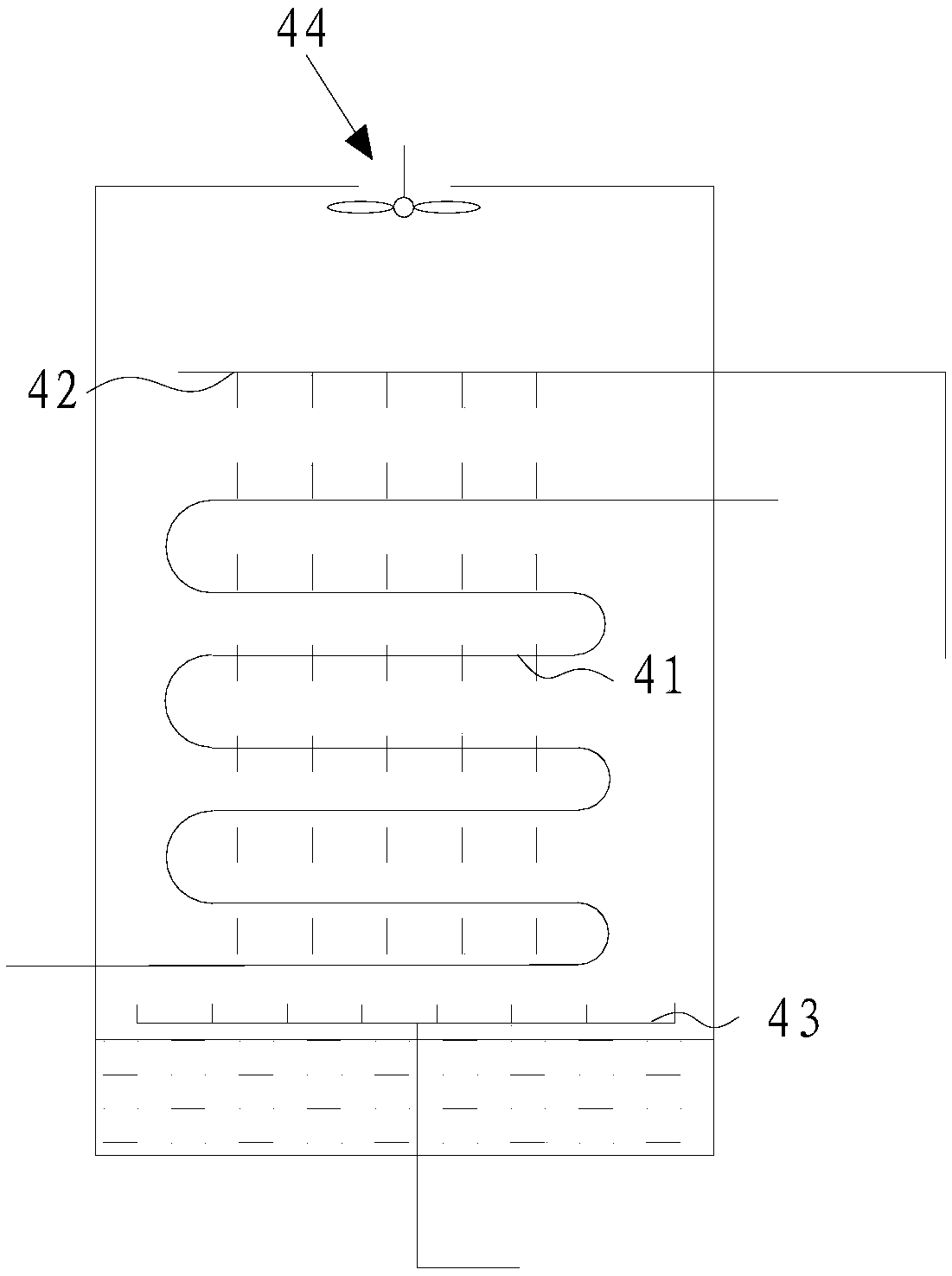

[0038] The reducer 4 is provided with a heat exchange coil 41 and a second spray unit 42 located above the heat exchange coil 41. The heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com