A double compensation device for abrasive belt polishing

An abrasive belt polishing and double compensation technology, applied in abrasive belt grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of slow compensation action, heavy polishing machine base, serious polishing quality, etc. The effect of stable polishing force and improved polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

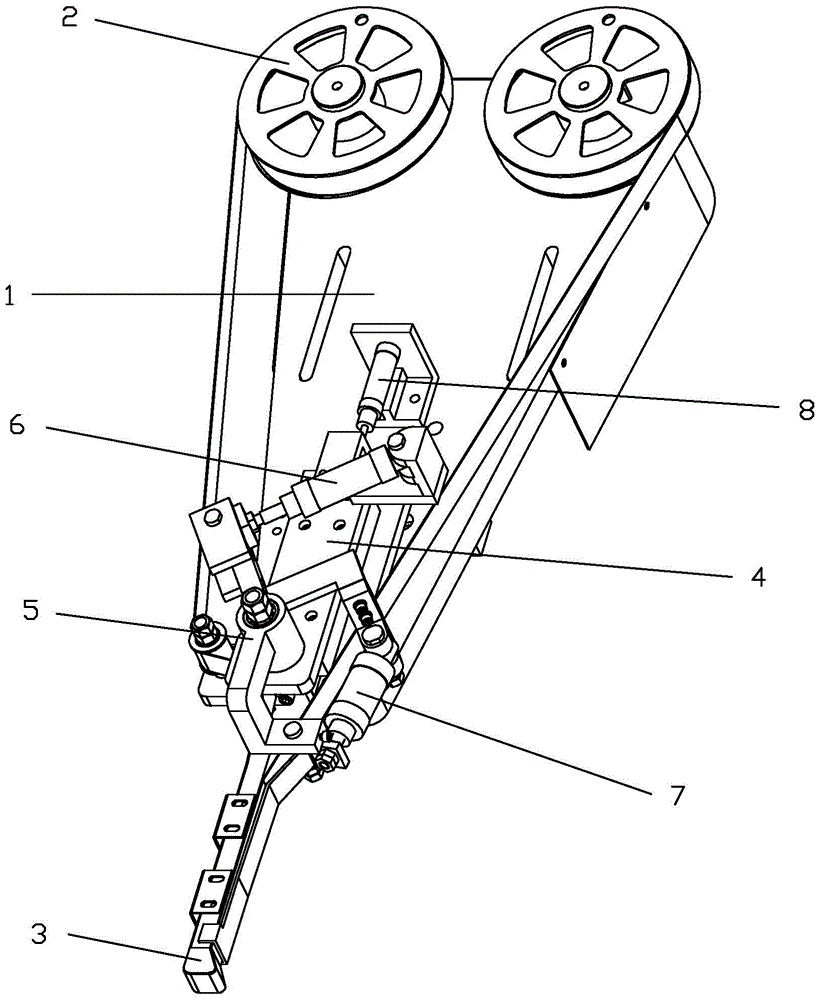

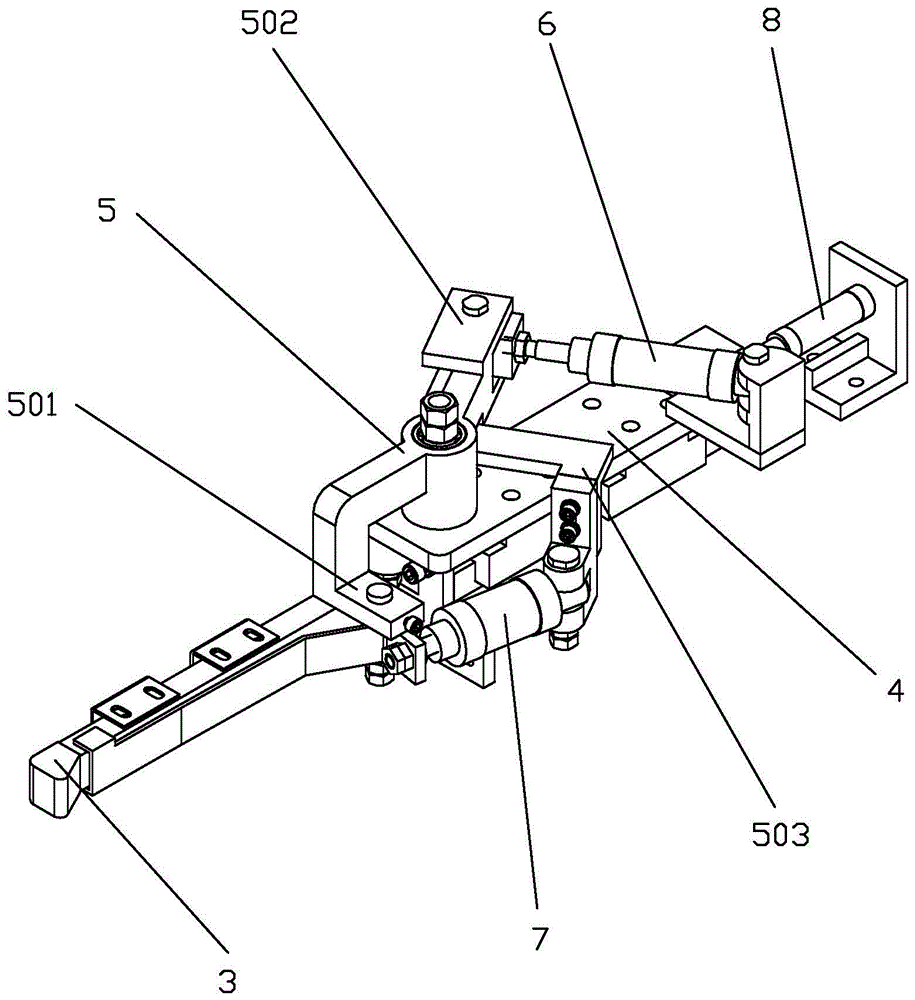

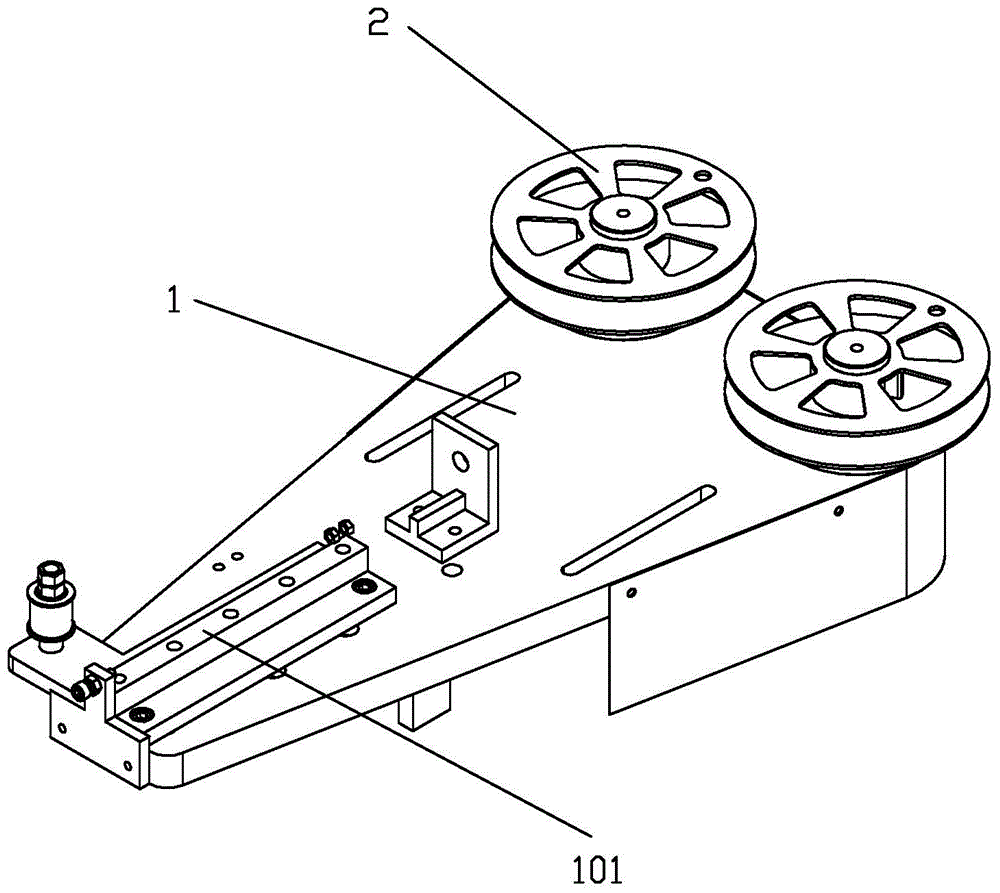

[0020] refer to Figure 1~Figure 7 , a double compensation device for abrasive belt polishing, including a frame 1, the frame 1 is provided with an abrasive belt driving mechanism 2 and a polishing head mechanism 3, and the front end of the frame 1 is provided with a sliding seat 4 that can slide back and forth , the sliding seat 4 is connected with a first power mechanism 8 for maintaining its forward pressure, the upper end surface of the sliding seat 4 is provided with a rotating shaft 401, and the adjusting frame 5 is hinged on the rotating shaft 401, and the adjusting frame 5 The first end portion 501 of the front end and the second end portion 502 of the rear end are provided, the first end portion 501 is connected with the polishing head mechanism 3, and the second end portion 502 is connected with a second end portion for pushing the adjustment frame 5 to rotate. The power mechanism 6, wherein preferably, the first power mechanism 8 and the second power mechanism 6 use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com