An arch breaking device and an impeller coal feeder

The technology of arch breaking and water gun is applied in the field of arch breaking device and impeller coal feeder, which can solve the problems of impeller coal feeder without coal that can be unloaded, labor intensity of workers, hidden dangers, etc., so as to ensure the normal coal feeding process and reduce the The labor intensity of workers and the effect of ensuring production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

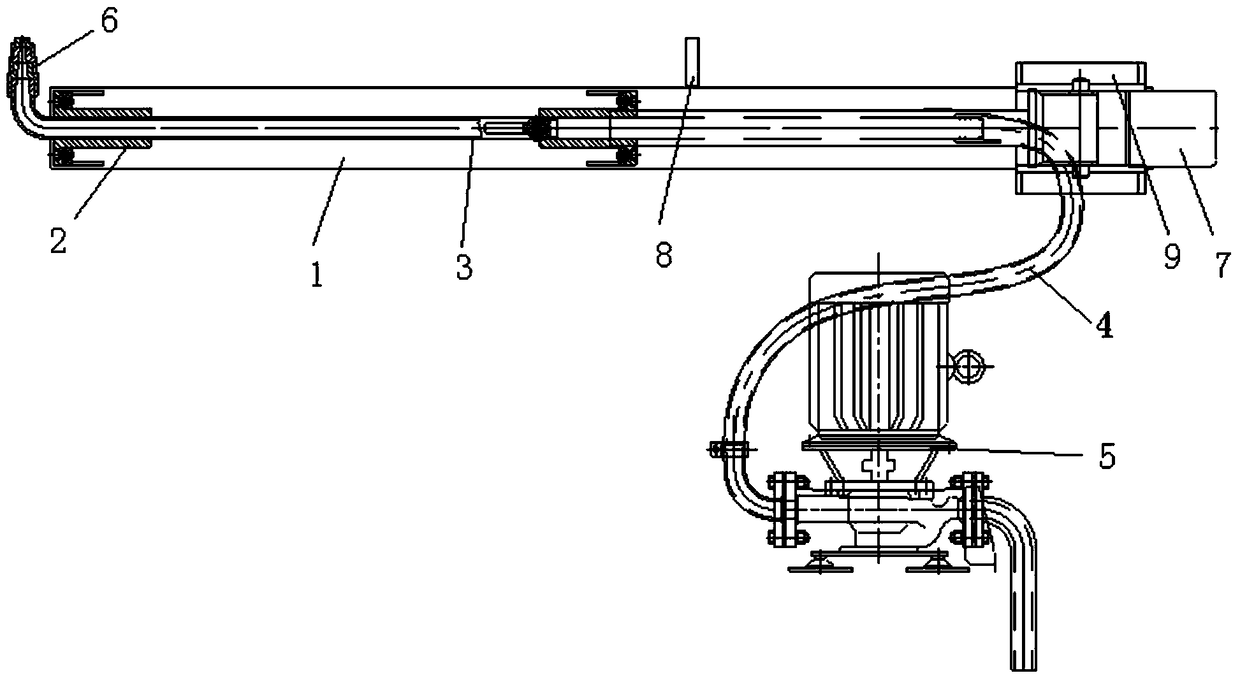

[0021] See attached figure 1 , with figure 1 A specific embodiment of an arch breaking device according to the present invention is provided, wherein, the attached figure 1 It is a schematic diagram of the overall structure of an arch breaking device according to Embodiment 1 of the present invention.

[0022] as attached figure 1 As shown, the arch breaking device provided by the present invention includes a base 1 , a guide cylinder 2 , a water gun 3 , a water delivery pipe 4 , a water pump 5 , a flow control nozzle 6 and a push-pull rod 7 .

[0023] The arch breaking device comprises a base 1, on which a guide cylinder 2 is arranged, and a water gun 3 is arranged in the guide cylinder 2, and the water gun 3 can move back and forth in the guide cylinder 2.

[0024] In the specific implementation process, the guide cylinder 2 is generally directly welded on the base 1, and the water gun 3 is generally directly inserted into the guide cylinder 2.

[0025] The water inlet e...

Embodiment 2

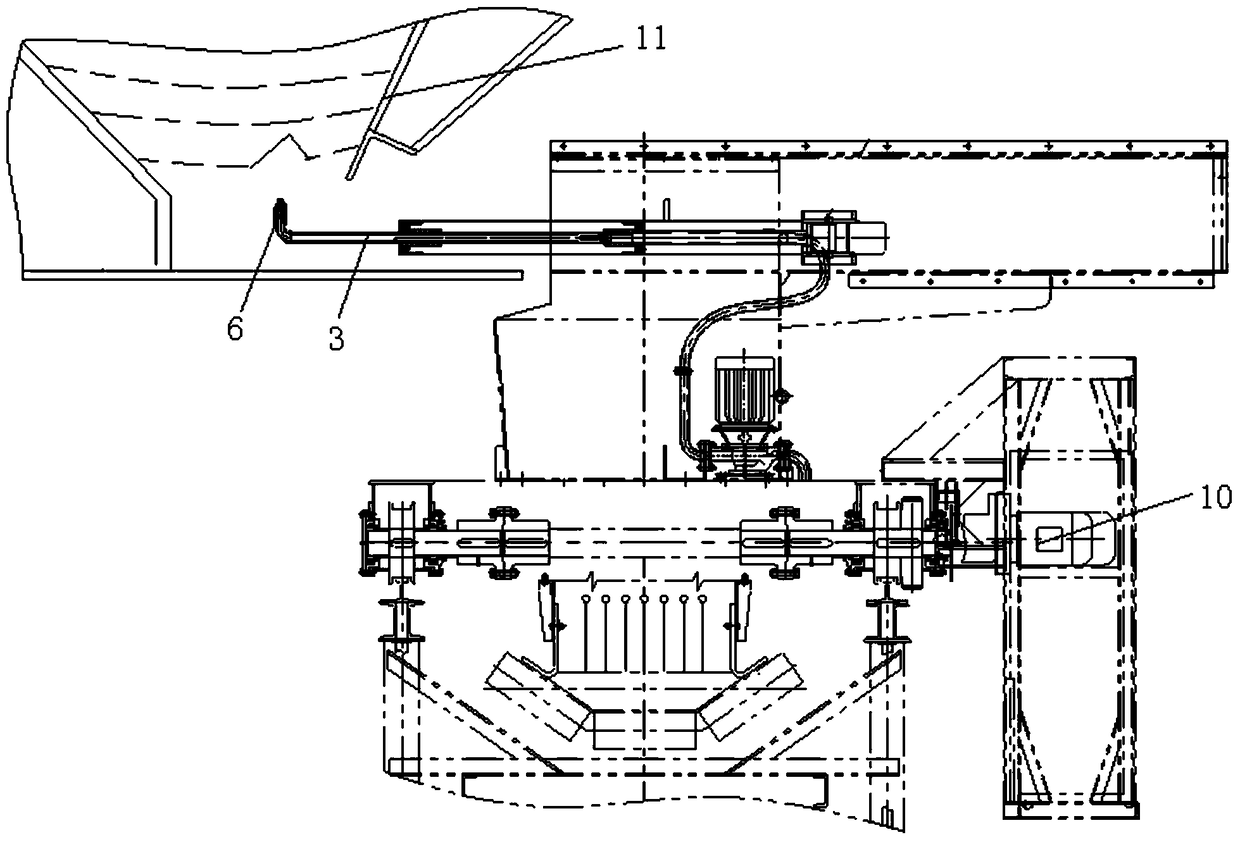

[0036] See attached figure 2 , with figure 2 A specific embodiment of an impeller coal feeder of the present invention is provided, wherein, the attached figure 2 It is a schematic diagram of the overall structure of an impeller coal feeder in Embodiment 2 of the present invention.

[0037] as attached figure 2 As shown, the impeller coal feeder 10 is equipped with the arch breaking device described in any one of the above.

[0038] When the impeller coal feeder 10 is used to transport the coal in the coal storage bunker 11, once the coal in the coal storage bunker 11 arches, the water gun 3 of the arch breaking device can be controlled to extend and retract until the flow is controlled The nozzle 6 is aimed at the arched part of the coal block in the coal storage bin 11, and then the high-pressure water flow is controlled by the flow control nozzle 6, and the arched coal block is broken in time to prevent the impeller coal feeder 10 from having no coal, and ensure that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com