Wrapped monolayer graphene oxide/ carbon nano tube compound and preparation method thereof

A technology of graphene nanosheets and carbon nanotubes, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of operation troubles, difficult method conditions, distribution of graphene oxide and carbon nanotubes Unevenness and other problems, to achieve the effect of simple method, uniform distribution and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

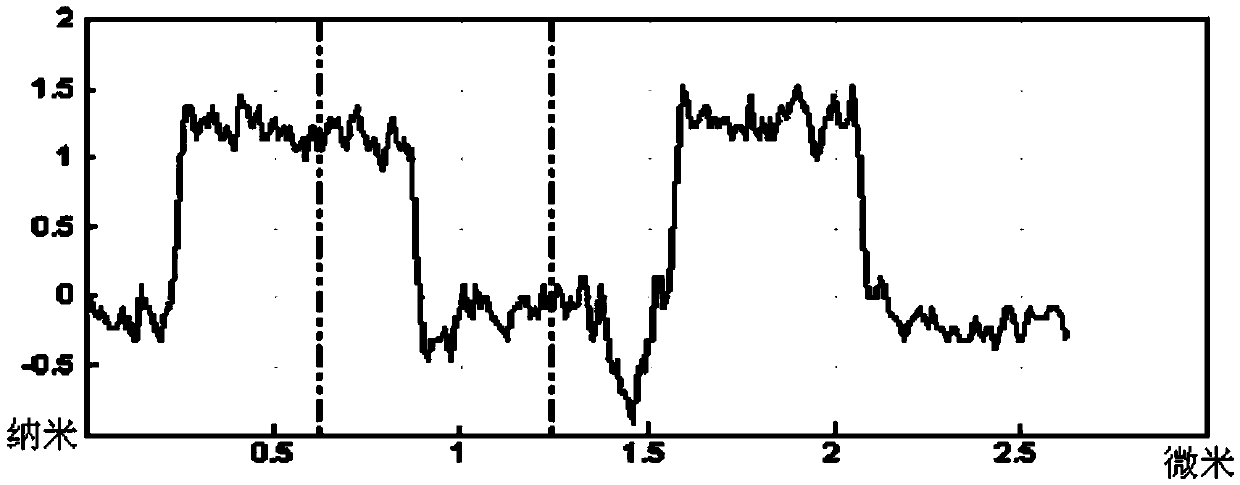

Image

Examples

Embodiment 1

[0057] (1) Preparation of single-layer graphene oxide nanosheets: graphite oxide was prepared by the modified Hummers method (Marcano, etc., ACSnano, 2010, 4(8):4806). Weigh 3g of graphite powder into a 500mL three-necked flask, add 360mL of concentrated H 2 SO 4 (98%) and 40mLH 3 PO 4 (85%), under ice bath condition, slowly add 18gKMnO 4 , kept the mixture at 50°C for 12 h, cooled the reaction mixture to room temperature, poured it on ice cubes made of 400 mL of deionized water, and slowly added about 3 mL of H 2 o 2 (30%), after the mixture was filtered, it was centrifuged and washed 5 times with HCl (10%) at 10,000 rpm. Next, the obtained product was put into a dialysis bag, dialyzed for 3 weeks, and then dried in a vacuum freeze dryer for 48 hours to a constant weight to obtain brown graphite oxide. Prepare a 1 mg / mL graphite oxide solution, ultrasonically strip it for 4 hours, use a high-speed centrifuge to centrifuge at 8,000rmp, take the centrifugate, and collect ...

Embodiment 2

[0063] Repeat Example 1, except that the time for the stripping described in step (1) is 6 hours by ultrasonic stripping, and the separation is by centrifugation, and the centrifuge is centrifuged at 6,000rmp for 50min, and the centrifuged liquid is taken out, collected and centrifuged at 12,000rmp for 20min The sediment A. The yield was 84%.

Embodiment 3

[0065] Repeat Example 1, except that the mass fraction of nitric acid in step (2) is 40%, the mass fraction of concentrated sulfuric acid is 80%, and the volume ratio of nitric acid and sulfuric acid is 1:2; The time is 3h; the time of ultrasonic cutting is 60min, and the ultrasonic power is 200W; the separation adopts centrifugation, and the centrifuge is centrifuged at 8,000rmp for 20min, the centrifugate is taken out, and the sediment that is centrifuged at 12,000rmp for 20min is collected b. After isolation, it was dried under vacuum at 80 °C. The yield was 56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com