Epoxy seal paint and preparation method thereof

A sealing paint and epoxy technology, which is applied in epoxy resin coatings, coatings, polyamide coatings, etc., can solve the problems that plague the research and development, production and construction of coatings, poor adhesion, poor compatibility, etc., and achieve good adhesion Sexuality, convenient production, and the effect of preventing alkali return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

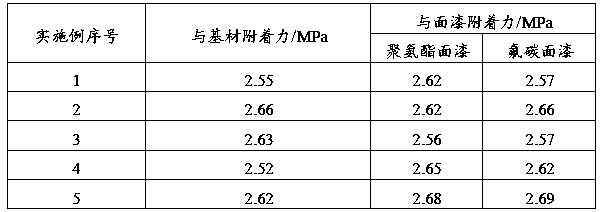

Examples

Embodiment 1

[0018] A kind of epoxy sealing paint, comprises main material and curing agent, wherein,

[0019] The main ingredient is composed of the following raw materials in parts by weight: 19 parts of epoxy resin, 58 parts of xylene, and 23 parts of n-butanol;

[0020] The curing agent is composed of the following raw materials in parts by weight: 48 parts of polyamide resin, 32 parts of xylene, 20 parts of n-butanol;

[0021] When using, mix the main paint and curing agent in a weight ratio of 5:1 and use it evenly.

[0022] The preparation method of the epoxy sealer of the present embodiment is as follows:

[0023] (1) 58g xylene and 23g n-butanol are added in the same reaction kettle and fully mixed to form a solution, 19g epoxy resin is added to the mixed solution, fully dissolved and then filtered and packaged to obtain the main ingredient;

[0024] (2) Add 32g xylene and 20g n-butanol into the same reaction kettle and fully mix to form a solution, add 48g polyamide resin to th...

Embodiment 2

[0027] A kind of epoxy sealing paint, comprises main material and curing agent, wherein,

[0028] The main ingredient is composed of the following raw materials in parts by weight: 17 parts of epoxy resin, 54 parts of xylene, and 27 parts of n-butanol;

[0029] The curing agent is composed of the following raw materials in parts by weight: 46 parts of polyamide resin, 38 parts of xylene, 14 parts of n-butanol;

[0030] When using, mix the main paint and curing agent in a weight ratio of 5:1 and use it evenly.

[0031] The preparation method of the epoxy sealer of this embodiment refers to Example 1.

Embodiment 3

[0033] A kind of epoxy sealing paint, comprises main material and curing agent, wherein,

[0034] The main ingredient is composed of the following raw materials in parts by weight: 24 parts of epoxy resin, 52 parts of xylene, and 28 parts of n-butanol;

[0035] The curing agent is composed of the following raw materials in parts by weight: 56 parts of polyamide resin, 31 parts of xylene, and 13 parts of n-butanol;

[0036] When using, mix the main paint and curing agent in a weight ratio of 5:1 and use it evenly.

[0037] The preparation method of the epoxy sealer of this embodiment refers to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com