Equipment for preparing xylooligosaccharide

A xylooligosaccharide and equipment technology, which is applied in the field of xylooligosaccharide preparation equipment, can solve problems such as incomplete reaction, blockage, and reduced output, and achieve the effect of high product quality and controllable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

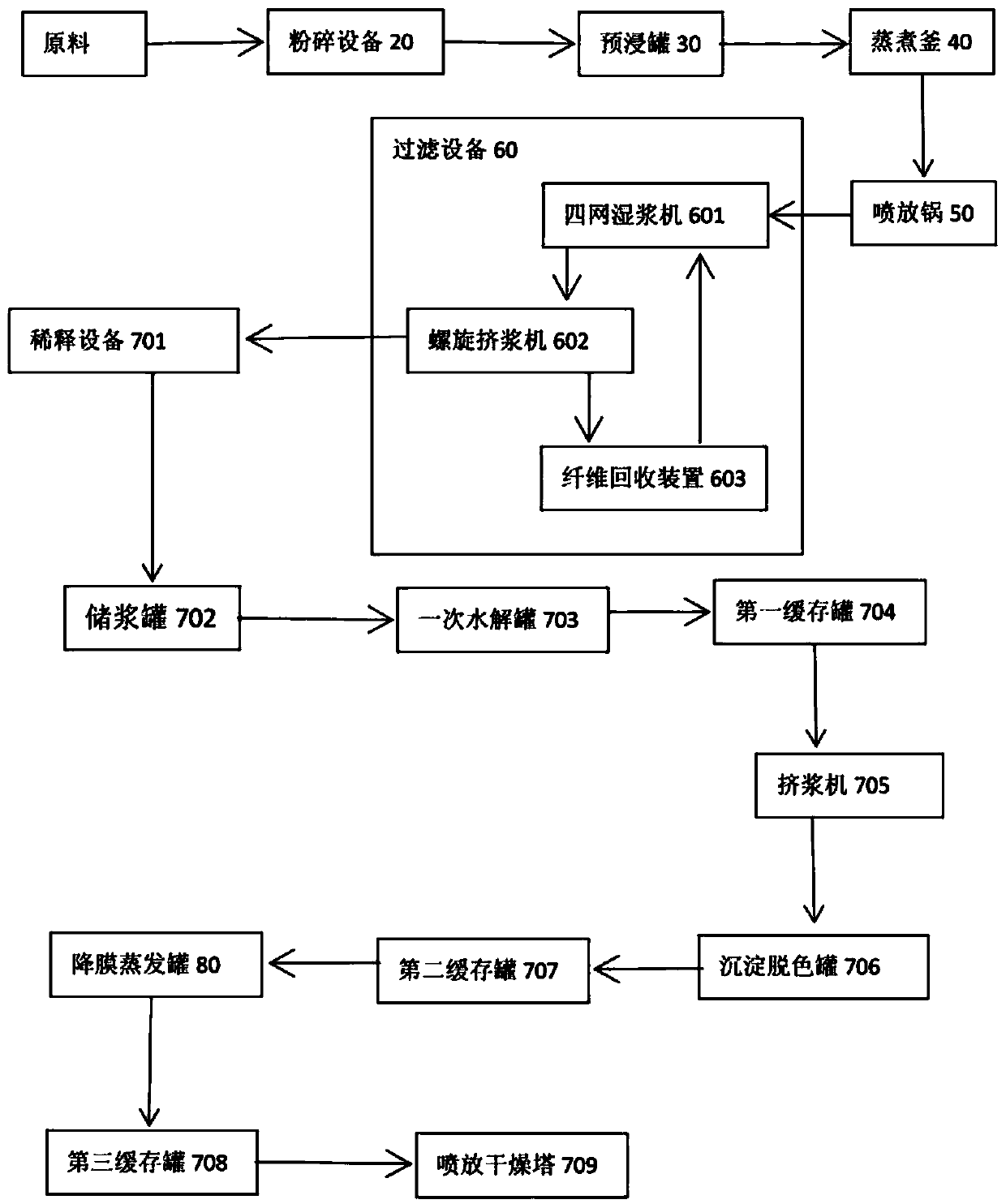

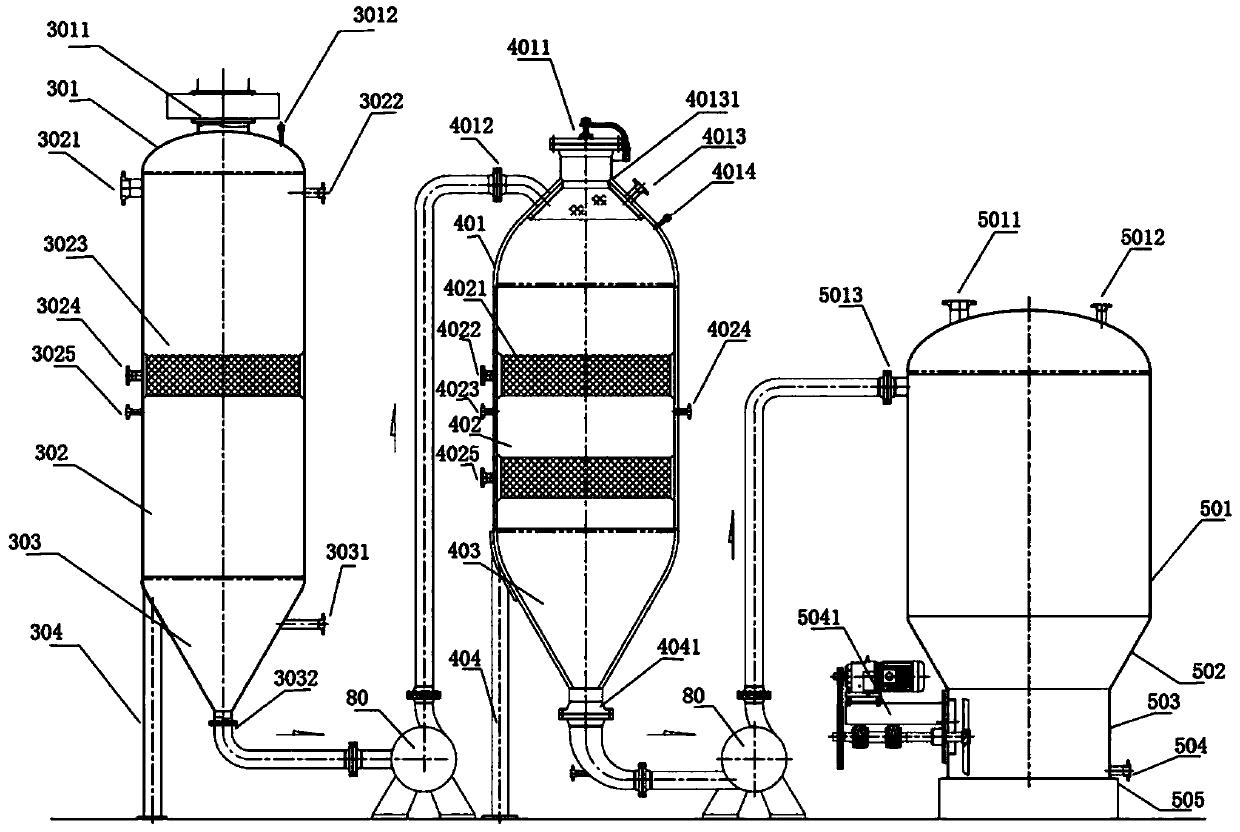

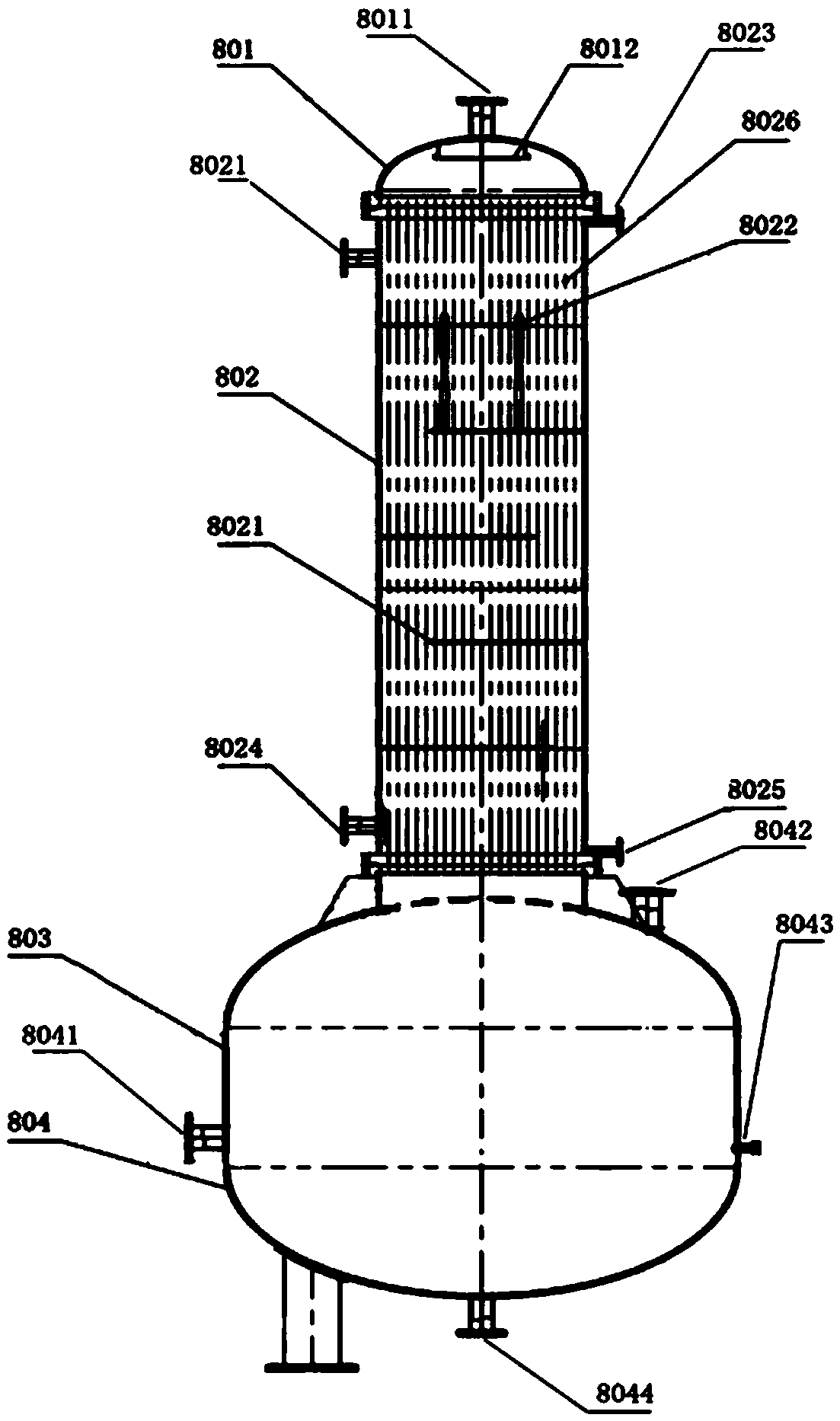

[0031] see Figure 1 to Figure 3 As shown, a line automatic pressure regulating device of the present invention includes: crushing equipment 20, prepreg tank 30, cooking kettle 40, spray pot 50, filtering equipment 60, dilution equipment 701, slurry storage tank 702, primary hydrolysis tank 703, the first buffer tank 704, the squeezer 705, the precipitation decolorization tank 706, the second buffer tank 707, the falling film evaporator 80, the third buffer tank 708 and the spray drying tower 709;

[0032] The pulverizing equipment 20 is used to pulverize the bamboo raw material; the prepreg tank 30 is used to soak the pulverized bamboo raw material in hot water to generate initial bamboo pulp; the cooking kettle 40 mixes the initial bamboo pulp with a catalyst, Carry out high-temperature and high-pressure cooking to obtain the reaction bamboo pulp, and spray it to the spray pot 50; after the spray pot 50 stirs the reaction bamboo pulp, the reaction bamboo pulp is separated fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com