Microwave oven adopting cylindrical oven chamber and taking helical antenna as radiator

A helical antenna and cylindrical technology, which is applied in the field of microwave ovens using a cylindrical furnace cavity and a helical antenna as a radiator, can solve the problems of microwave radiation, uneven heating of heated objects, furnace weight, and complex structure. Achieve the effects of improving the uniformity of heating and energy utilization, uniform heating, and light weight of the furnace body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

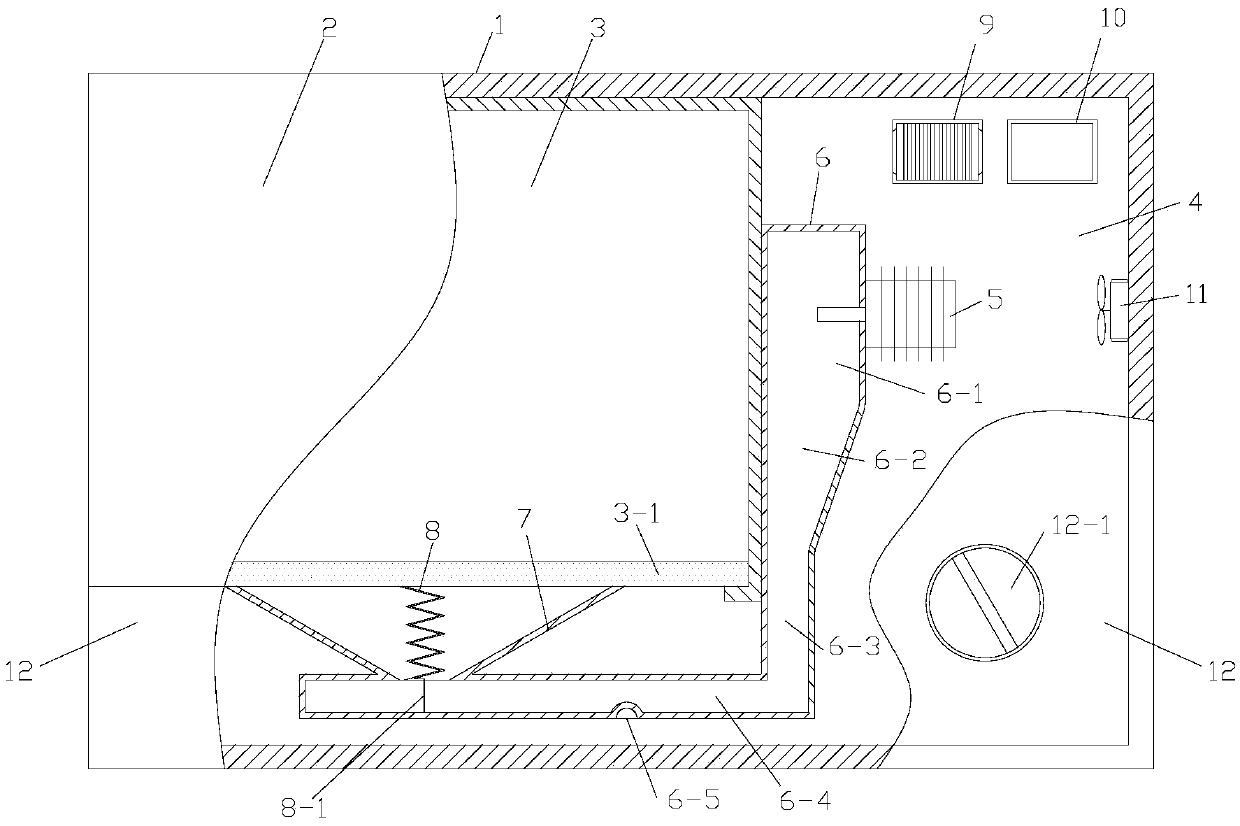

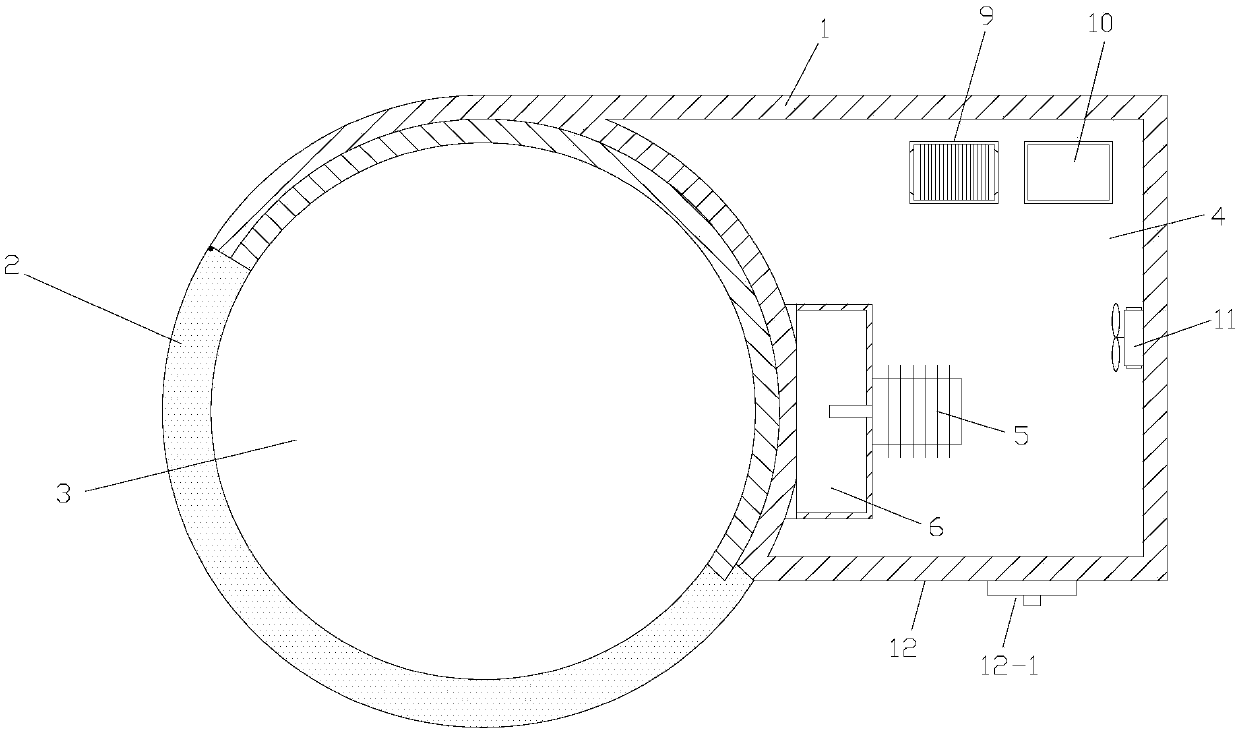

[0011] Embodiment 1: This embodiment takes a household microwave oven with a rated input power of 1200W (output power of 750W) and a microwave operating frequency of 2450MHz as an example: shell 1. (height×width) 330×500mm, the shell diameter of the furnace cavity is φ350mm, the electrical box The top of the position is 260mm deep; the furnace door 2 is a semi-cylindrical shell-shaped furnace door with an outer diameter of φ350mm and a height of 285mm; the furnace cavity 3 has an internal diameter of φ300mm and a height of 220mm. (diameter * thickness) glass-ceramic plate of φ300 * 5mm; Magnetron 5. Model 2M219, operating frequency F=2450MHz; The vertical waveguide total height in " L " shape waveguide 6 is 187mm, wherein: (microwave) The excitation section 6-1 is a rectangular waveguide with a cavity height of 70mm up and down, a lateral width of 40mm, and a depth of 80mm. (Vertical waveguide) An inverted trapezoidal transitional waveguide section with the same cross-section ...

Embodiment 2

[0012] Embodiment two: present embodiment furnace chamber 3 inner diameters, high 220mm, (furnace chamber) bottom plate 3-1 is all identical with embodiment one, and the present embodiment of furnace chamber top board adopts the parabolic top board that protrudes upwards, and the parabolic surface top board of this top board The microwave energy reflected from the upper surface has the function of radial convergence, which can further improve the heating efficiency; other parts are also the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com