Vacuum high-temperature solar heat collecting tube

A solar collector tube and vacuum technology, applied in the field of vacuum high-temperature solar collector tubes, can solve the problems of high temperature resistance of the heat absorbing layer, high heat radiation loss of the heat collector tube, and low light-to-heat conversion efficiency, and achieve good weather resistance and long service life Long-term, heat radiation loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

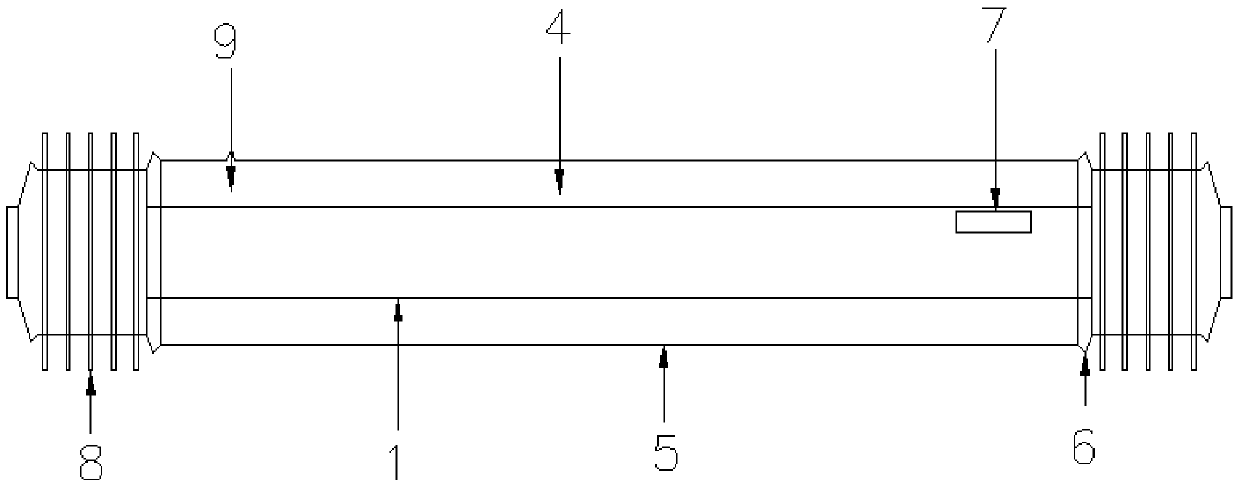

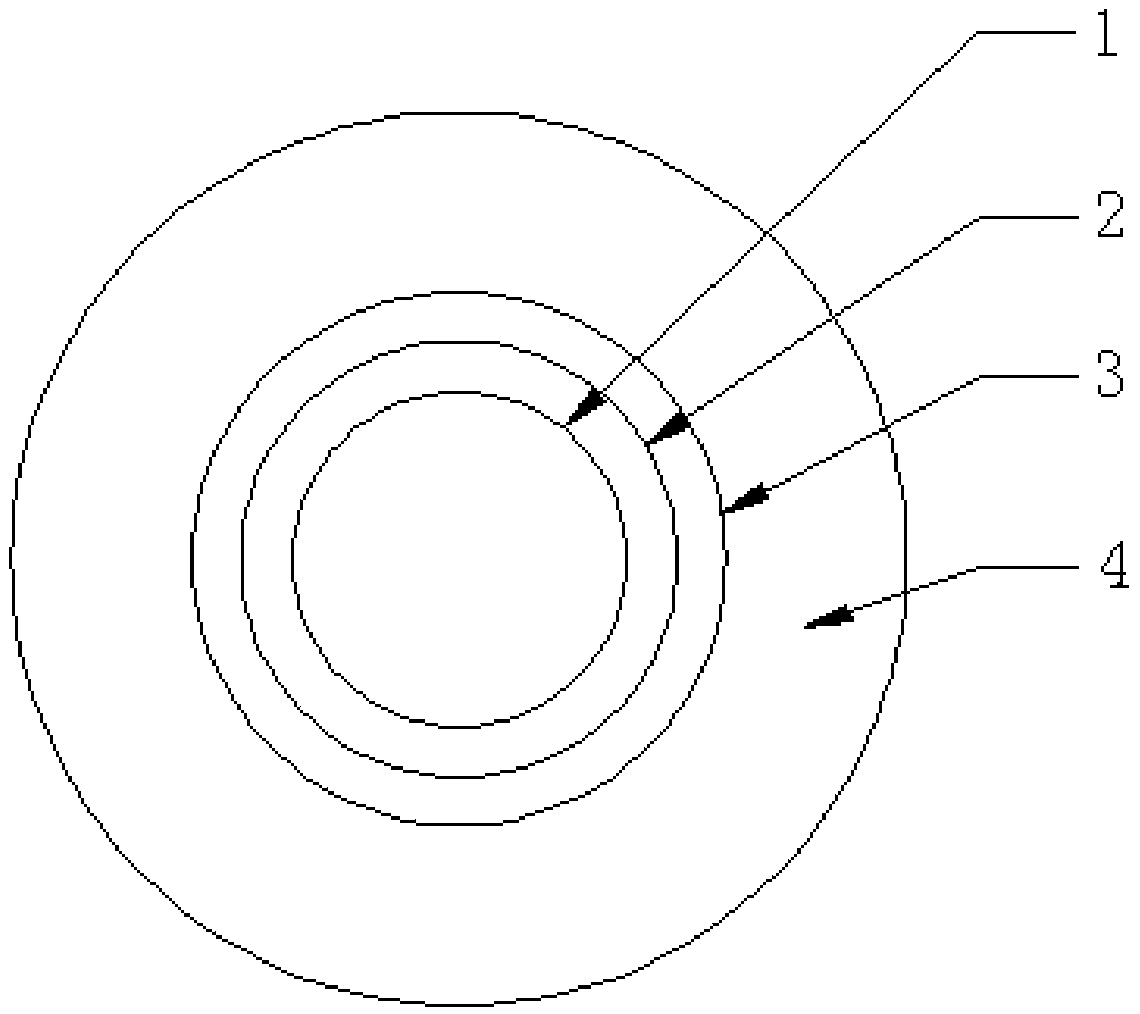

[0027] A vacuum high-temperature solar heat collection tube, comprising a base tube 1, a Kovar alloy 6, a glass cover 5 and a corrugated tube 8, characterized in that the outer wall of the base tube 1 is sequentially provided with an absorbing coating 2, a reducing A reflective coating 3; a base pipe 1 and an absorbing coating 2 and an anti-reflection coating 3 positioned on the outer wall of the base pipe 1 are fixedly sleeved in the glass cover 5; an air suction port 9 is provided above the glass cover 5, so After the glass cover 5 is evacuated, a vacuum insulation layer 4 is formed;

[0028] The Kovar 6 fixes the glass cover 5 at both ends of the bellows 8;

[0029] The base pipe 1 is made of stainless steel; the longitudinal section of the base pipe 1 is circular;

[0030] A vacuum indicating device 7 is arranged above the glass cover 5;

[0031] The absorption coating 2 is a ceramic composite material of nickel and molybdenum, and the absorption coating 2 is calculated ...

Embodiment 2

[0039] A vacuum high-temperature solar heat collection tube, comprising a base tube 1, a Kovar alloy 6, a glass cover 5 and a corrugated tube 8, characterized in that the outer wall of the base tube 1 is sequentially provided with an absorbing coating 2, a reducing A reflective coating 3; a base pipe 1 and an absorbing coating 2 and an anti-reflection coating 3 positioned on the outer wall of the base pipe 1 are fixedly sleeved in the glass cover 5; an air suction port 9 is provided above the glass cover 5, so After the glass cover 5 is evacuated, a vacuum insulation layer 4 is formed;

[0040] The Kovar 6 fixes the glass cover 5 at both ends of the bellows 8;

[0041] The base pipe 1 is made of stainless steel; the longitudinal section of the base pipe 1 is circular;

[0042] A vacuum indicating device 7 is arranged above the glass cover 5;

[0043] The absorption coating 2 is a ceramic composite material of nickel and molybdenum, and the absorption coating 2 is calculated ...

Embodiment 3

[0052] A vacuum high-temperature solar heat collection tube, comprising a base tube 1, a Kovar alloy 6, a glass cover 5 and a corrugated tube 8, characterized in that the outer wall of the base tube 1 is sequentially provided with an absorbing coating 2, a reducing A reflective coating 3; a base pipe 1 and an absorbing coating 2 and an anti-reflection coating 3 positioned on the outer wall of the base pipe 1 are fixedly sleeved in the glass cover 5; an air suction port 9 is provided above the glass cover 5, so After the glass cover 5 is evacuated, a vacuum insulation layer 4 is formed;

[0053] The Kovar alloy 5 fixes the glass cover 4 at both ends of the bellows 8;

[0054] The base pipe 1 is made of stainless steel; the longitudinal section of the base pipe 1 is circular;

[0055] A vacuum indicating device 7 is arranged above the glass cover 5;

[0056] The absorption coating 2 is a ceramic composite material of nickel and molybdenum, and the absorption coating 2 is calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com