Weather-proof packaging glue for assembling solar energy photoelectric panel

A solar photovoltaic panel, weather-resistant technology, applied in the field of encapsulation hot melt adhesive, can solve the problems of decreased bonding strength, affecting power generation efficiency, affecting light transmittance, etc., so as to improve the bonding strength, ensure power generation efficiency, and improve weather resistance performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

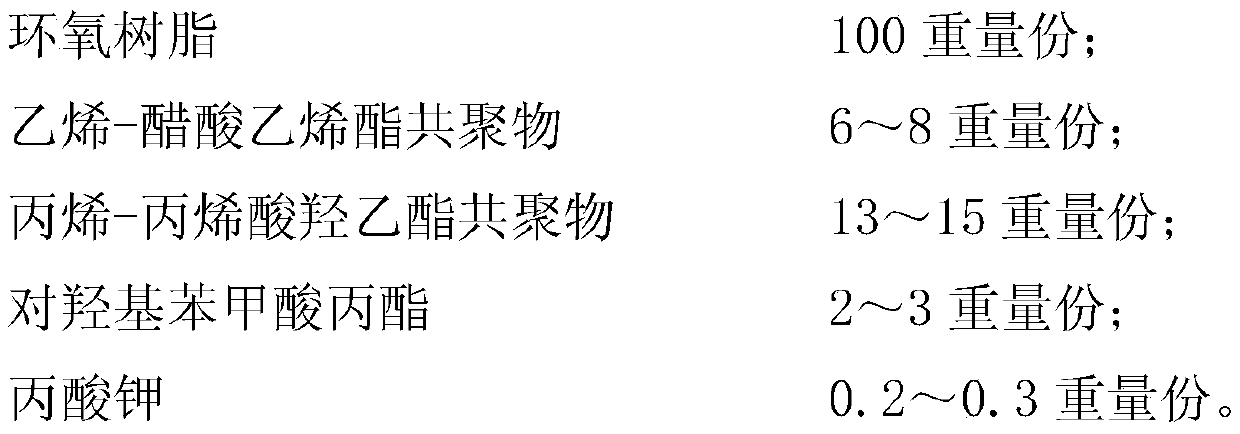

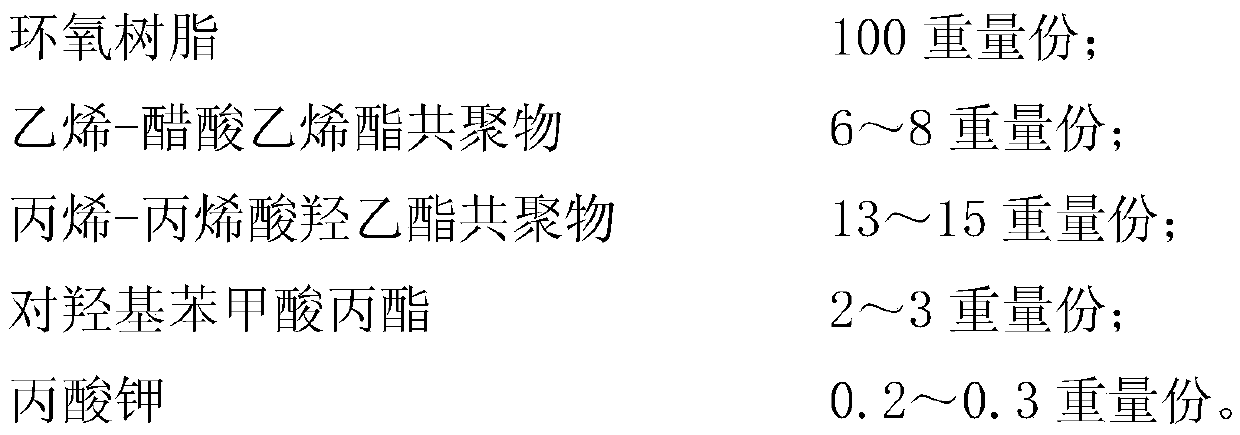

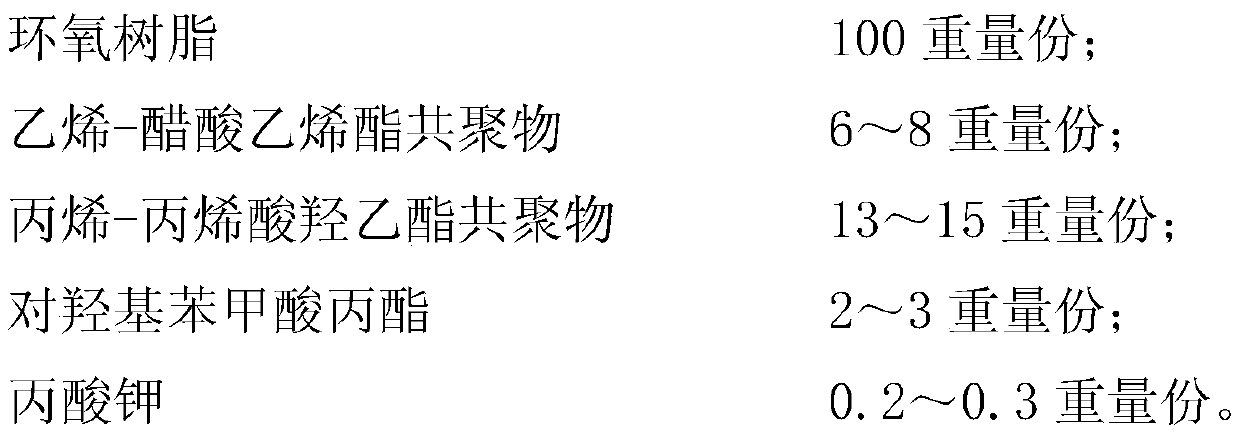

[0016] This case proposes an embodiment of a weather-resistant encapsulant for solar photovoltaic panel assembly, including the following materials by weight:

[0017]

[0018] In the above embodiments, in the ethylene-vinyl acetate copolymer, the ethylene content is preferably 40-42 wt%, and the rest is vinyl acetate.

[0019] In the above embodiments, the number average molecular weight of the ethylene-vinyl acetate copolymer is preferably 20000-22000 g / mol.

[0020] In the above embodiments, in the propylene-hydroxyethyl acrylate copolymer, the content of propylene is preferably 56-58 wt%, and the rest is hydroxyethyl acrylate.

[0021] In the above embodiments, the number average molecular weight of the propylene-hydroxyethyl acrylate copolymer is preferably 18000-20000 g / mol. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com