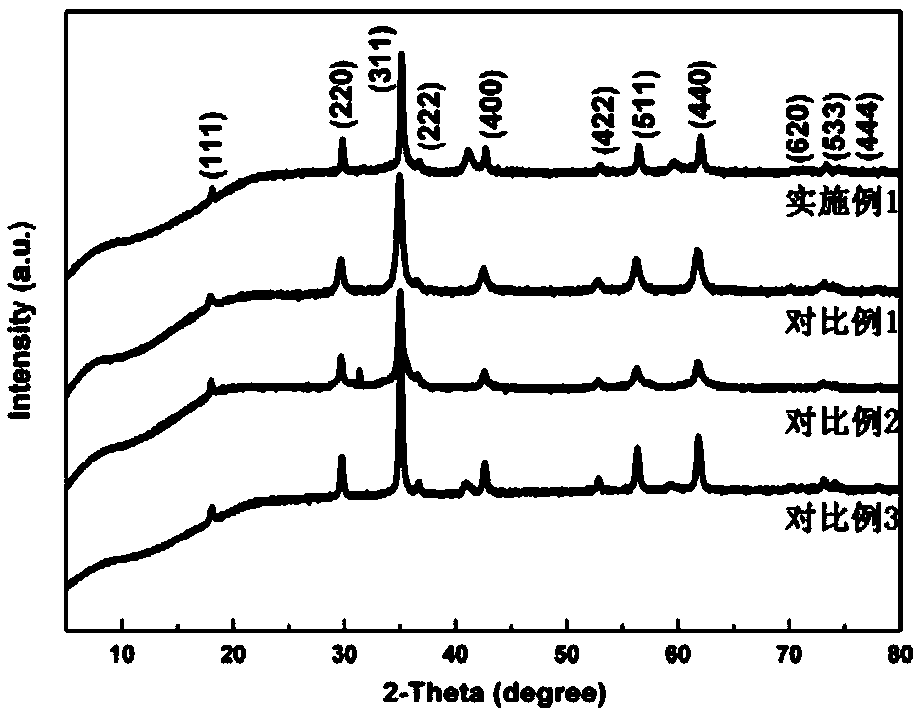

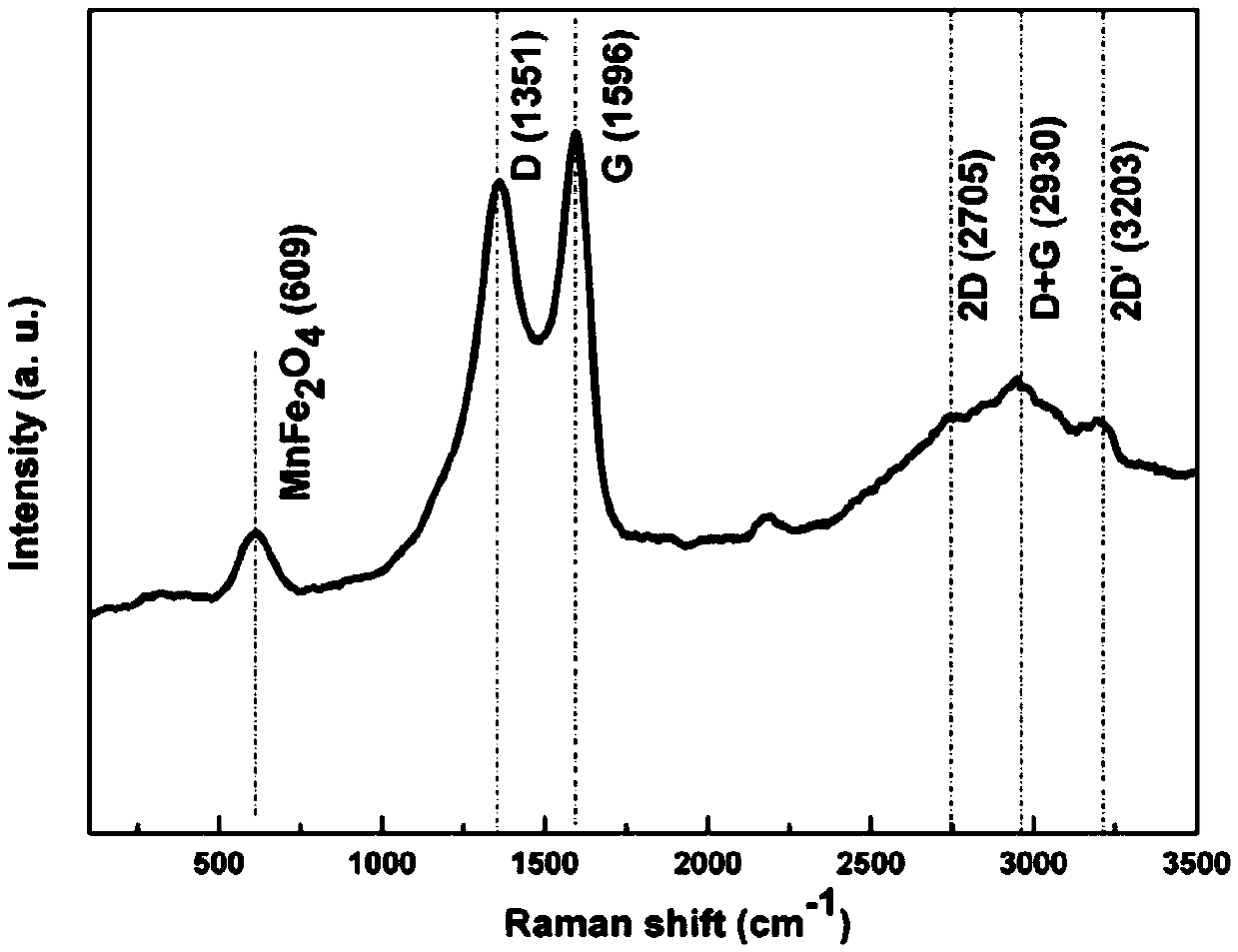

Process for preparing lithium ion battery anode material MnFe2O4/rGO with hydrothermal method

A lithium-ion battery and anode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limited application, large volume expansion rate, high resistivity, etc., and achieve improved recombination degree, excellent electrochemical performance, crystallization degree of improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

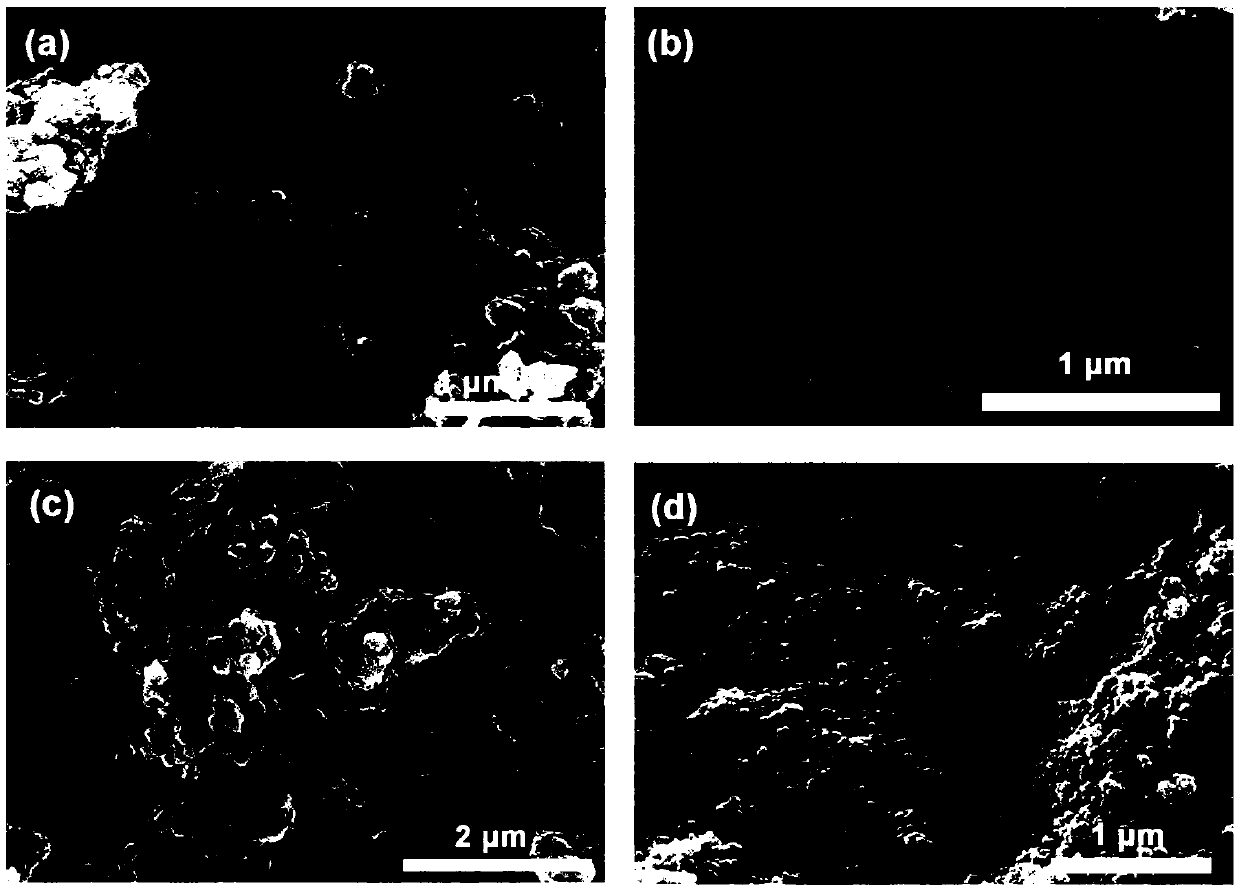

Embodiment 1

[0033] (1) adopt improved Hummers method to prepare graphite oxide powder;

[0034] (2) Disperse 20 mg of the graphite oxide powder obtained in step (1) in 20 mL of water, stir for 10 min, and sonicate for 3 h to form dispersion A;

[0035] (3) Add 20 mL of ethylene glycol to the dispersion A obtained in step (2), and add 0.2 g of polyvinylpyrrolidone (molecular weight: 58,000), and sonicate for 10 minutes to form dispersion B;

[0036] (4) 10mL of MnCl 2 4H 2 O solution (1mol / L) and 10mL of FeCl 3 ·6H 2 O solution (2mol / L) joins in the dispersion liquid B that obtains in step (3), stirs 30min, forms mixed liquid C;

[0037] (5) Slowly add 1.5 mL of ammonia water with a mass concentration of solute of 25% to the mixed solution C obtained in step (4), and stir for 1 hour to form mixed solution D;

[0038] (6) Add 20 mg of sodium borohydride to the mixed liquid D obtained in step (5), stir for 10 min, then transfer to the reaction kettle, and react at 180° C. for 10 h;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible specific capacity | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com