A kind of method that is produced ethylene by acetate

A technology of acetate and ethylene, applied in chemical instruments and methods, bulk chemical production, hydrocarbons, etc., can solve the problems of acetic acid price drop, acetic acid overcapacity, etc., and achieve the effect of broadening raw material channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

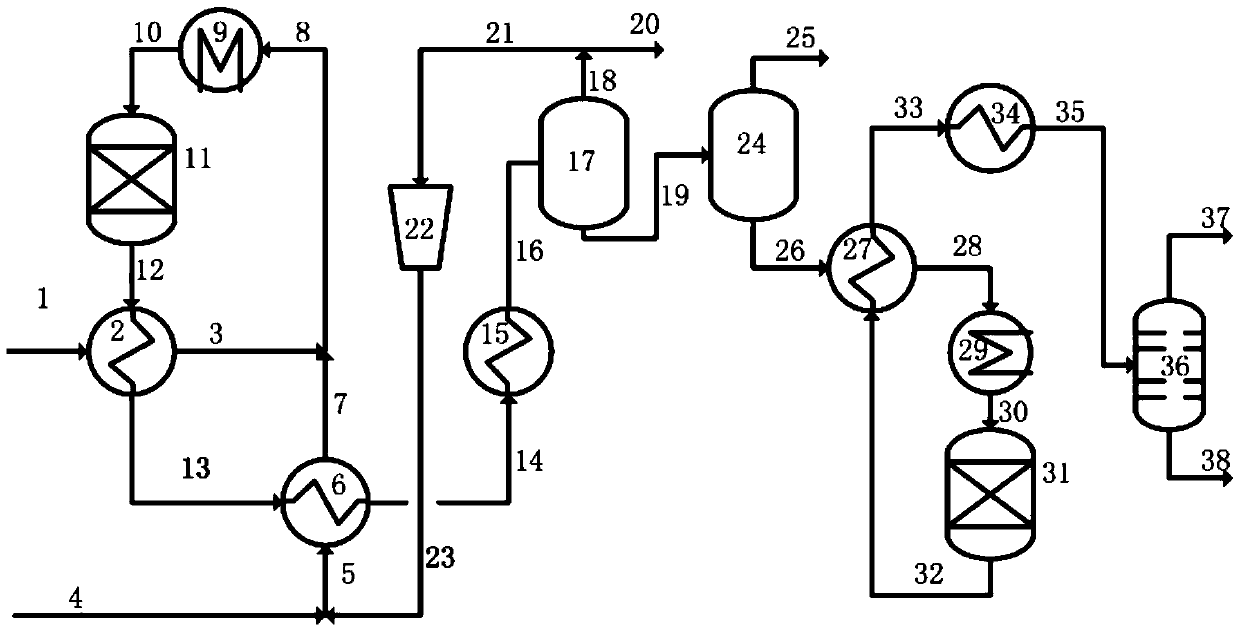

[0038] Combine below figure 1 Specific embodiments will be described.

[0039] Embodiment Gas chromatography is used to analyze the concentration of acetate and ethylene before and after the reaction, so as to calculate the conversion rate of acetate and the selectivity of ethylene.

[0040] Ethyl acetate 1 is pumped into the acetate preheater 2 through a high-pressure liquid feed pump, wherein the feed rate of ethyl acetate 1 is 150mol / h, and the high-temperature hydrogenation product gas 12 from the hydrogenation reactor 11 is in the acetate preheater 2. Heat exchange preheating occurs in the preheater 2 to obtain ethyl acetate vapor 3 at 250°C. The mixed hydrogen 5 obtained after the hydrogen 4 is mixed with the high-pressure cycle gas 23 is fed into the hydrogen preheater 6, wherein the flow rate of the hydrogen 4 is 27Nm 3 / h, after heat exchange, high-temperature hydrogen gas 7 with a temperature of 230°C is obtained.

[0041]Mix high-temperature hydrogen gas 7 and et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com