Method for preparing fused mullite from bauxite under coal

A technology of electric melting mullite and bauxite, which is applied in the field of refractory materials, can solve the problems of high content of impurities such as iron and sulfur, poor endowment of bauxite, low aluminum content, etc., to achieve large processing capacity, good crystal development, The effect of high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

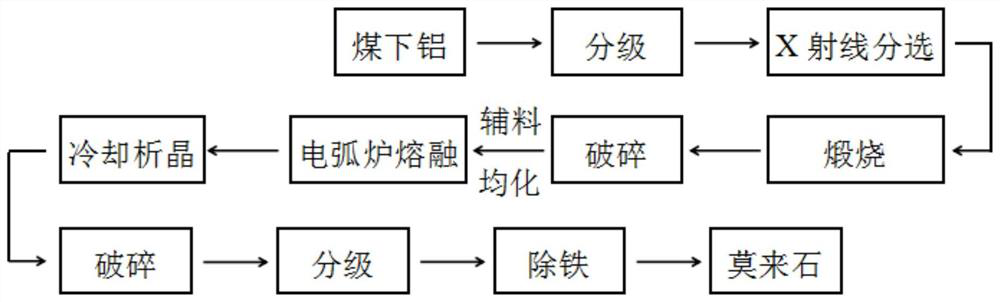

[0029] Such as figure 1 As shown, a method for preparing fused mullite from bauxite under coal, specifically:

[0030] (1) Main components of bauxite under coal, w(Al 2 o 3 ) is 54.40%, w(SiO 2 ) is 19.35%, w(Fe 2 o 3 ) is 7.34%, w(S) is 0.52%, w(TiO 2 ) is 2.50%, w(Na 2 O+K 2 O) is 0.48%; after the bauxite under the coal is graded and eliminated 2 o 3 ) to 4.06%, w (S) to 0.11%, to obtain intermediate minerals;

[0031] (2) Send the intermediate minerals into the rotary kiln for 4 hours for calcination, and the calcination temperature is 1150°C to obtain bauxite clinker;

[0032] (3) The bauxite clinker is crushed to ≤1.5mm, and then 90wt% of the bauxite clinker, 7.0wt% silica, 1.8wt% coke (charcoal) and 1.2wt% sawdust are mixed to obtain the batch;

[0033] (4) Send the batch material into an electric arc furnace at 1950°C for high temperature melting for 1.5 hours; after cooling for 24 hours, crush, classify, and remove iron by magnetic separation (magnetic field ...

Embodiment 2

[0035] Such as figure 1 As shown, a method for preparing fused mullite from bauxite under coal, specifically:

[0036] (1) Main components of bauxite under coal, w(Al 2 o 3 ) is 59.12%, w(SiO 2 ) is 14.37%, w(Fe 2 o 3 ) is 3.38%, w(S) is 0.36%, w(TiO 2 ) is 2.25%, w(Na 2 O+K 2 O) is 0.44%; after the bauxite under the coal is graded and eliminated 2 o 3 ) to 2.71%, w (S) to 0.09%, to obtain intermediate minerals;

[0037] (2) The intermediate minerals are then sent to a rotary kiln for calcination for 5 hours at a calcination temperature of 1200°C to obtain bauxite clinker;

[0038] (3) The bauxite clinker is broken to less than 1.5mm, and then after mixing the bauxite clinker of 88wt%, the silica of 9.5%wt, the coke (charcoal) of 1.5%wt and the sawdust proportioning of 1wt%, get batch materials;

[0039] (4) Send the batch material into an electric arc furnace at 2000°C for high temperature melting for 0.9h; after cooling for 35h, crush, classify, and remove iron by m...

Embodiment 3

[0041] Such as figure 1 As shown, a method for preparing fused mullite from aluminum under coal, specifically:

[0042] (1) Main components of bauxite under coal, w(Al 2 o 3 ) is 64.24%, w(SiO 2 ) is 14.70%, w(Fe 2 o 3 ) is 2.12%, w(S) is 0.27%, w(TiO 2 ) is 2.55%, w(Na 2 O+K 2 O) is 0.47%; the bauxite under the coal is graded and eliminated 2 o 3 ) to 1.6%, w(S) to 0.06%, to obtain intermediate minerals;

[0043] (2) The intermediate minerals are then sent to a rotary kiln for calcination for 3 hours at a calcination temperature of 1250°C to obtain bauxite clinker;

[0044] (3) The bauxite clinker is broken to less than 1.5mm, and then 90wt% bauxite clinker, 8.5wt% silica, 1.0wt% coke (charcoal) and 0.5wt% sawdust are mixed evenly to obtain a compound material;

[0045] (4) The batch material is sent to 2050°C electric arc furnace for high temperature melting for 0.7h; after cooling for 40h, it is crushed, classified, and magnetically separated to remove iron (magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com