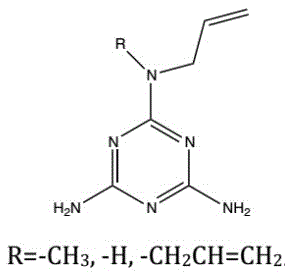

Fire retardant containing allyl substituted triazine carbon-forming agent and preparation method of same

A technology of allyl substitution and carbon-forming agent is applied in the application field of flame retardants to achieve the effects of improving production safety, non-toxic and harmless operating environment, and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

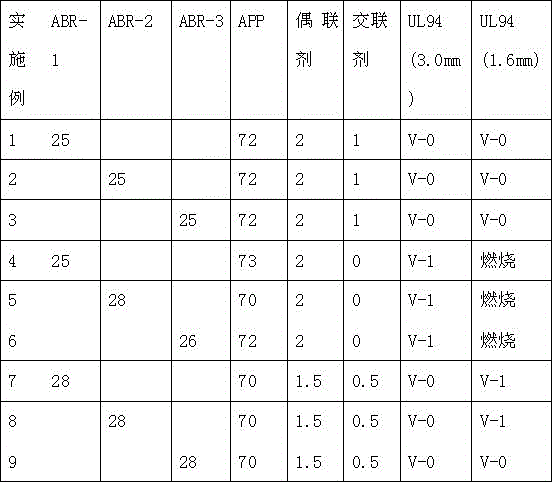

Embodiment 1

[0028] Add commercially available concentrated ammonia (25%-28%) and water equal to the volume of ammonia to a four-necked flask equipped with a stirrer, a solid feeder, a thermometer, a reflux condenser, and a gas absorption device, and then add monoallyl The base amine was stirred to form a homogeneous solution and cooled to 0-5°C. Under vigorous stirring, add cyanuric chloride solid in batches, and keep the temperature of the reaction system below 10°C during the whole addition process; after the addition is complete, continue to stir and react for 1 hour; raise the temperature to 45-55°C, and keep it at this temperature React for 2 hours; heat up to 90°C, and keep at this temperature for 4 hours; after the reaction, filter, wash, and dry to obtain the monoallyl-substituted melamine (hereinafter referred to as cyanuric chloride, allylamine and ammonia water) The reaction molar ratio is 1:1:5.5.

Embodiment 2

[0030] Add commercially available concentrated ammonia (25%-28%) and water equal to the volume of ammonia to a four-necked flask equipped with a stirrer, a solid feeder, a thermometer, a reflux condenser, and a gas absorption device, and then add N-formazan Stir allyl amine to form a homogeneous solution, cool to 0-5°C; under vigorous stirring, add cyanuric chloride solid in batches, and keep the temperature of the reaction system below 10°C during the entire addition process; after the addition is complete, continue Stir the reaction for 2 hours; raise the temperature to 45-55°C, and keep it at this temperature for 4 hours; raise the temperature to 92°C, and keep it at this temperature for 5 hours; after the reaction, filter, wash, and dry to obtain the product-N -Methyl-N-allyl-melamine (hereinafter referred to as ABR-2); the reaction molar ratio of cyanuric chloride, allylamine and ammonia water is 1:1:5.8.

Embodiment 3

[0032] Add commercially available concentrated ammonia (25%-28%) and water equal to the volume of ammonia to a four-necked flask equipped with a stirrer, a solid feeder, a thermometer, a reflux condenser, and a gas absorption device, and then add diallyl Stir the base amine to form a homogeneous solution, cool to 0-5°C, add cyanuric chloride solid in batches under vigorous stirring, and keep the temperature of the reaction system below 10°C during the entire addition process; after the addition is complete, continue to stir and react for 2 hour; be warmed up to 45-55 ℃, and keep at this temperature for 4 hours; be warmed up to 95 ℃, and keep at this temperature for 4 hours; Diallyl melamine (hereinafter referred to as ABR-3); the reaction molar ratio of cyanuric chloride, allylamine and ammonia water is 1:1:6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com