Starch/PVA composite antibacterial preservative film and preparation method thereof

A composite antibacterial and fresh-keeping film technology, which is applied in the field of polymer materials, can solve the problems that vinyl antibacterial preservation is difficult to degrade and affect the mechanical properties of products, so as to achieve excellent mechanical properties, improve tensile properties and elongation at break, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

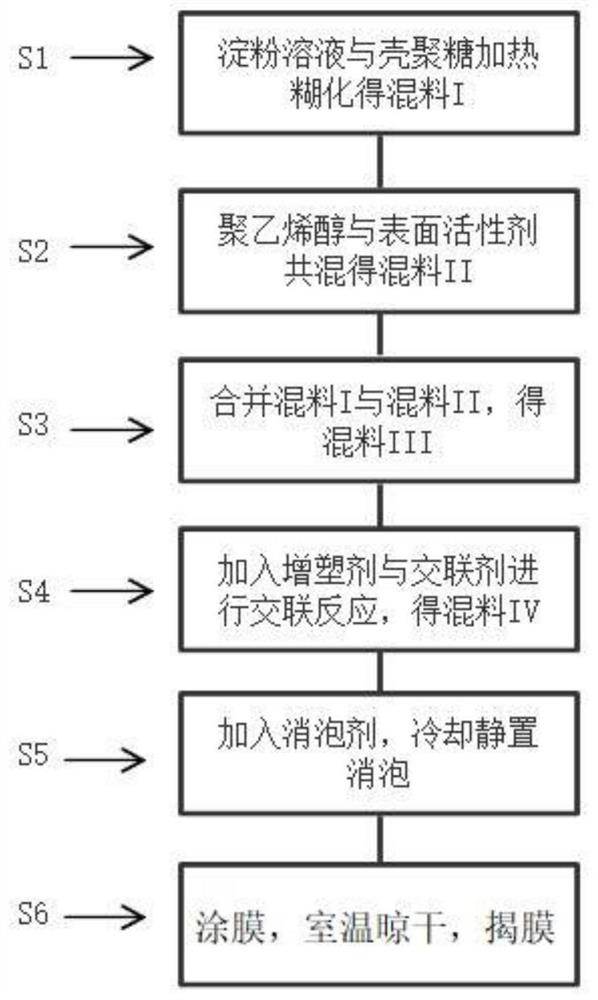

Method used

Image

Examples

Embodiment 1

[0037] A kind of starch / PVA composite antibacterial fresh-keeping film, comprises the following components by weight:

[0038] 100 copies of PVA;

[0039] 20 parts of starch;

[0040] Chitosan 10 parts;

[0041] 5 parts of plasticizer;

[0042] 0.5 parts of crosslinking agent;

[0043] 0.5 part of surfactant;

[0044] 1 part of defoamer;

[0045] 200 parts of water.

[0046] Wherein, the degree of polymerization of the PVA is 2000, and the degree of alcoholysis is 85%; the amylose content in the starch is 58%; the average relative molecular mass of the chitosan is 6×10 5 A mixture of high molecular weight chitosan and low molecular weight chitosan with an average relative molecular mass of 5000, the molar ratio of the high molecular weight chitosan to the low molecular weight chitosan is 1:1.

[0047] Compared with ordinary PE-based cling film, two hydrophilic polymers, starch and PVA, are used in this example as substrates, and the obtained cling film will not strongly...

Embodiment 2

[0061] A kind of starch / PVA composite antibacterial fresh-keeping film, comprises the following components by weight:

[0062] 100 copies of PVA;

[0063] 40 parts of starch;

[0064] Chitosan 20 parts;

[0065] 5 parts of plasticizer;

[0066] 0.5 parts of crosslinking agent;

[0067] 0.5 part of surfactant;

[0068] 1 part of defoamer;

[0069] 300 parts of water.

[0070] Wherein, the degree of polymerization of the PVA is 2000, and the degree of alcoholysis is 85%; the amylose content in the starch is 58%; the average relative molecular mass of the chitosan is 6×10 5 A mixture of high molecular weight chitosan and low molecular weight chitosan with an average relative molecular mass of 5000, the molar ratio of the high molecular weight chitosan to the low molecular weight chitosan is 1:1.

[0071] Other conditions are with embodiment 1.

Embodiment 3

[0073] A kind of starch / PVA composite antibacterial fresh-keeping film, comprises the following components by weight:

[0074] 100 copies of PVA;

[0075] 20 parts of starch;

[0076] Chitosan 10 parts;

[0077] 5 parts of plasticizer;

[0078] 0.5 parts of crosslinking agent;

[0079] 0.5 part of surfactant;

[0080] 1 part of defoamer;

[0081] 200 parts of water.

[0082] Wherein, the degree of polymerization of the PVA is 2000, and the degree of alcoholysis is 85%; the amylose content in the starch is 58%; the average relative molecular mass of the chitosan is 6×10 5 The mixture of the high molecular weight chitosan and the low molecular weight chitosan of average relative molecular weight 5000, the molar ratio of the high molecular weight chitosan and the low molecular weight chitosan is 2:1.

[0083] Other conditions are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com