Local prestress assembly type energy-dissipating beam column joint

A beam-column joint and prestressing technology, which is applied in the direction of architecture and building construction, can solve the problems of affecting the overall mechanical performance of prefabricated beams, the heavy workload of perforating prestressed tendons, and the high tension of prestressed tension, so as to benefit post-earthquake Repair, facilitate rapid repair, improve energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

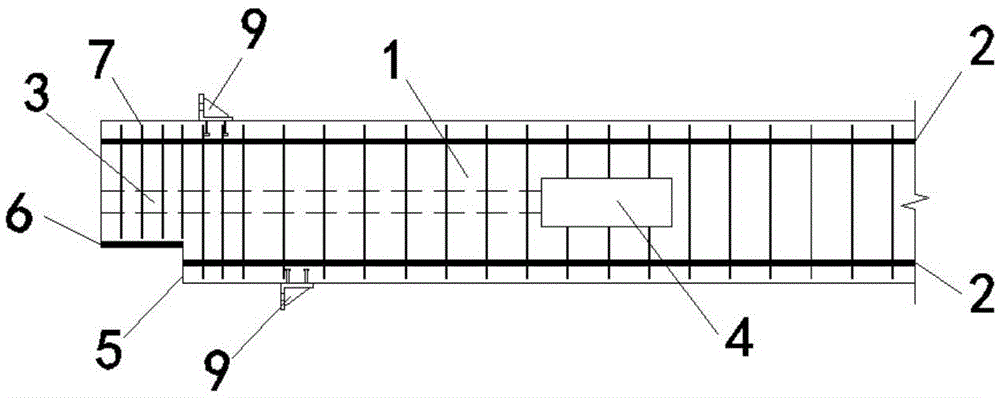

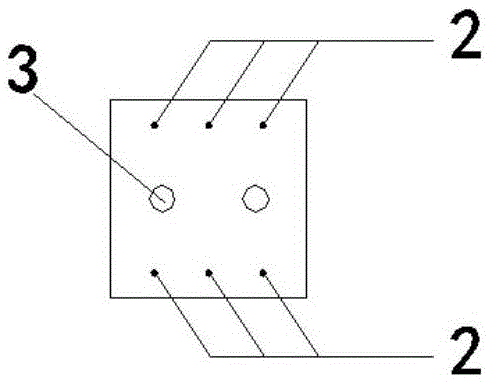

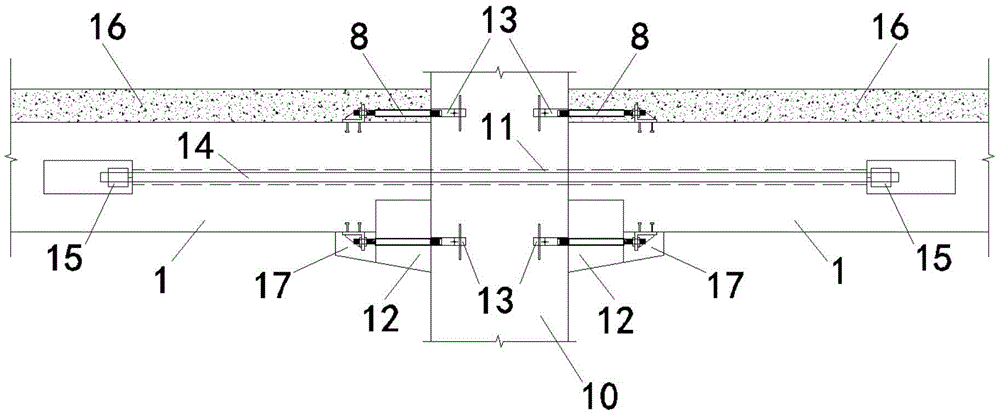

[0029] Such as Figure 1-4 As shown: the upper and lower sections of the precast concrete beam 1 are provided with pre-tensioned prestressed tendons 2 according to the calculation requirements, and are made by the long-line method pedestal; the prestressed tendon tunnel 3 is left at the middle position of the section height of the end of the beam, which is arranged symmetrically from left to right. The length is reasonably calculated according to the deformation requirements of the prestressed tendon; the tail of the prestressed tendon channel 3 is bent to the side of the beam, leaving space for tensioning and anchoring of the prestressed tendon 4 . There is a corbel 5 at the lower part of the beam end section, and a pressure-bearing end plate 6 is set at the position of the corbel, and the stirrups 7 at the corbel and nearby positions are encr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com