Egg and coix seed crisp cake and manufacturing method thereof

A production method and egg technology, which are applied in the directions of baking, dough processing, baked food, etc., can solve the problems of poor health care function, poor taste, single nutrient composition, etc., and achieve convenient consumption, high functionality and high nutrient composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: An egg and barley crisp, including 52kg of flour, 15kg of powdered sugar, 1.1kg of syrup, 13kg of palm oil, 1.1kg of barley flour, 4.2kg of liquid cream, 4.2kg of cornstarch, 0.22kg of salt, 2.2kg of eggs, egg yolk Powder 1.1kg, flavoring 0.17kg, soda 0.22kg, butterfat 0.16kg, milk flavoring powder 0.16kg and water 6kg, and adding an appropriate amount of starch can improve the viscoelasticity of barley crisps, making it easy to make, and can also greatly improve the quality of eggs. The nutritional value of barley crisp, its preparation method comprises the following steps:

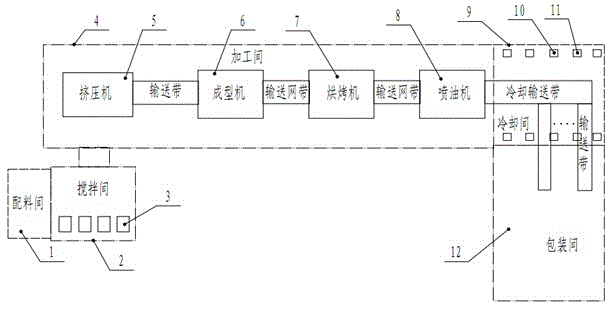

[0030] (1) Ingredients: Mix the ingredients according to the required ratio evenly;

[0031] (2) Stirring: Put the uniformly mixed material in step (1) into the mixer and stir it into dough, the stirring speed is 25 rpm, and the stirring time is 3~5 minutes;

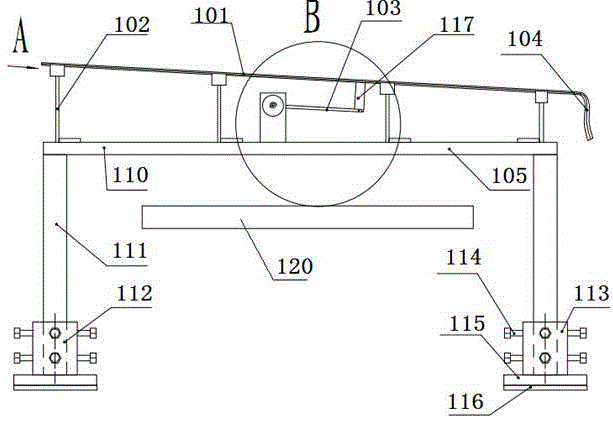

[0032] (3) Extrusion molding: put the dough mixed in step (2) into an extruder, and extrude it into a sheet-like dough piece wi...

Embodiment 2

[0039] Example 2: An egg barley crisp, including 48kg flour, 13kg powdered sugar, 0.9kg syrup, 11kg palm oil, 0.9kg barley rice flour, 3.8kg liquid cream, 3.8kg cornstarch, 0.2kg salt, 1.8kg egg, egg yolk Powder 0.9kg, Flavor 0.15kg, Soda 0.22kg, Butyrin 0.15kg, Milk Flavor Powder 0.15kg and Water 5.5kg (1) Ingredients: Mix the ingredients according to the required ratio;

[0040] (2) Stirring: Put the uniformly mixed material in step (1) into the mixer and stir it into dough, the stirring speed is 25 rpm, and the stirring time is 3~5 minutes;

[0041] (3) Extrusion molding: put the dough mixed in step (2) into an extruder, and extrude it into a sheet-like dough piece with uniform thickness, and shape the thin-plate-shaped dough piece into a crisp piece by a molding machine;

[0042] (4) Baking: Transport the formed crisps in step (3) to a baking oven through a conveyor belt for 18 to 20 minutes;

[0043] (5) Fuel injection: transport the baked crisps in step (4) to the fuel ...

Embodiment 3

[0048] Example 3: An egg and barley crisp, including 50kg of flour, 14kg of powdered sugar, 1kg of syrup, 12kg of palm oil, 1kg of barley flour, 4kg of liquid butter, 4kg of cornstarch, 0.21kg of salt, 2kg of eggs, 1kg of egg yolk powder, flavoring 0.16kg, 0.2kg of soda, 0.16kg of milk fat, 0.16kg of milk powder and 6kg of water (1) Ingredients: Mix the ingredients according to the required ratio;

[0049] (2) Stirring: Put the uniformly mixed material in step (1) into the mixer and stir it into dough, the stirring speed is 25 rpm, and the stirring time is 3~5 minutes;

[0050] (3) Extrusion molding: put the dough mixed in step (2) into an extruder, and extrude it into a sheet-like dough piece with uniform thickness, and shape the thin-plate-shaped dough piece into a crisp piece by a molding machine;

[0051] (4) Baking: Transport the formed crisps in step (3) to a baking oven through a conveyor belt for 18 to 20 minutes;

[0052] (5) Fuel injection: transport the baked crisp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com