Novel composite material based on metal-organic framework material and carbon nanotube and preparation method of novel composite material

A metal-organic framework, carbon nanotube technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor symmetry, insufficient coordination of metal ions, poor stability of self-assembled structures, etc., and achieve the best adsorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]0.5 g of unmodified carbon nanotubes were placed in a mixture of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1), ultrasonically treated at 80°C for 8 h, rinsed with a large amount of deionized water and cleaned with a pore size of 0.2 μm The polytetrafluoroethylene microporous membrane was vacuum-filtered to collect the carbon nanotubes; and then repeatedly rinsed with deionized water until the filtrate was neutral, and then vacuum-dried at 80° C. for 24 hours to obtain the acidified carbon nanotubes. Place the acidified carbon nanotubes in thionyl chloride and keep stirring and refluxing for 12 hours at 80°C, then collect the carbon nanotubes by suction filtration or centrifugation under reduced pressure; then repeatedly use anhydrous tetrahydrofuran to wash the obtained carbon nanotubes at 90°C Vacuum drying for 24 h to obtain acid chloride carbon nanotubes. Dissolve 1 g of 2-aminoterephthalic acid in 100 ml of anhydrous dimethylformamide, a...

Embodiment 2

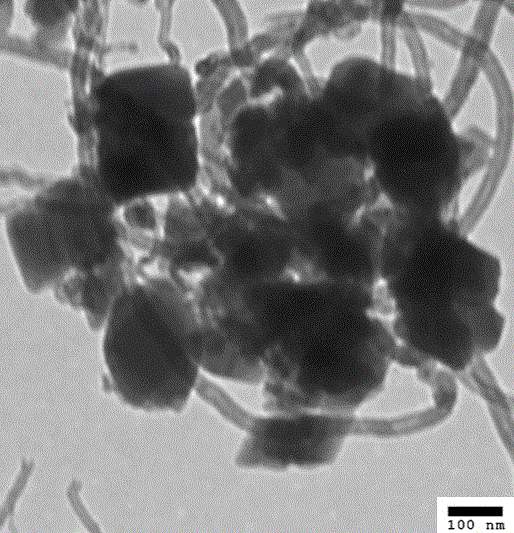

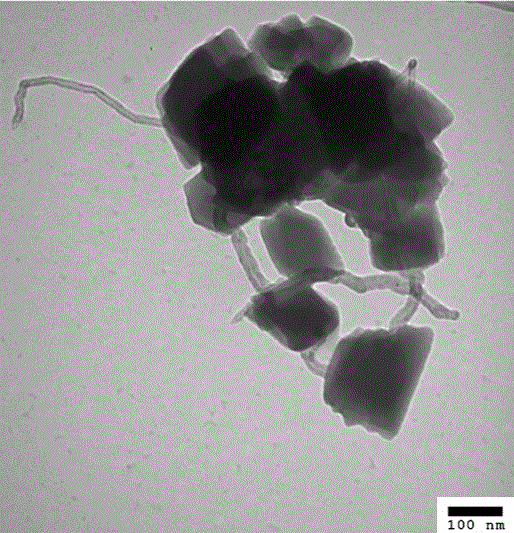

[0032] The embodiment of chemical modification of carbon nanotubes is the same as that of Example 1. The embodiment used to prepare the composite material is the same as that of Comparative Example 2, but in NH 2 0.01 g of chemically modified carbon nanotubes were added to the synthesis system of _MIL-101(Fe). Prepared by microwave synthesis, carbon nanotubes / NH 2 _MIL-101(Fe). figure 1 is the carbon nanotube / NH prepared in this example 2 _MIL-101 (Fe) nanoparticle transmission electron microscope, the measured adsorption results of this example are shown in Table 1.

[0033] figure 1 and figure 2 It can be seen that the morphology of the synthesized composite materials are cubic crystals of linear carbon nanotubes in series metal organic framework materials. Comparing the adsorption properties in Table 1 and Table 2, the adsorption capacity of the prepared carbon nanotube / MOF composite material is significantly higher than that of carbon nanotubes and metal organic fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com