ag@sio 2 Modification of core-shell structure modified g‑c 3 no 4 Preparation method of photocatalytic fiber

A technology of modification and core-shell structure, applied in chemical instruments and methods, physical/chemical process catalysts, water/sludge/sewage treatment, etc., can solve the problems that the research literature of continuous fibers has not yet been published, and achieve easy recycling Utilization, mild reaction conditions, high raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

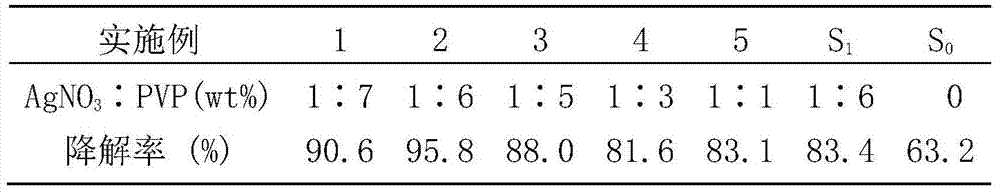

[0022] This example is based on 0.3g of g-C 3 N 4 , AgNO with a mass ratio of 1:7 3 and PVP mixed solution, that is, weigh 0.3g of g-C 3 N 4 , 0.25g AgNO 3 and 1.75g PVP. The specific steps are as follows:

[0023] (1) Add 0.3g of g-C 3 N 4 Add it to 80ml of APAM aqueous solution with a concentration of 0.4-1g / L, adjust the pH value of the dispersion to 1-3 with dilute hydrochloric acid, and disperse evenly by ultrasonication for 30 minutes. The homogeneous mixture was ultrasonically treated for 4 hours, separated by centrifugation, washed with deionized water, and then dispersed into 10ml of PVP aqueous solution with a concentration of 1.7-2g / L to obtain g-C with a concentration of 24.4mg / ml 3 N 4 nanosheet dispersion.

[0024] (2) Dissolve 1.75g of PVP in 100ml of ethylene glycol, and add 0.25g of AgNO 3 , control the temperature so that the temperature of the oil bath reaches 130° C. within 20 to 30 minutes and keep it warm for 1 hour. After cooling down to ...

Embodiment 2

[0031] This example is based on 0.3g of g-C 3 N 4 , AgNO with a mass ratio of 1:6 3 Prepared with the mixed solution of PVP, the difference between its concrete steps and Example 1 is:

[0032] AgNO 3 :PVP was mixed at a mass ratio of 1:6. That is, 1.50g of PVP was dissolved in 100ml of ethylene glycol, and 0.25g of AgNO was added under the conditions of heating and stirring in an oil bath 3 Make it dissolve, control the temperature so that the temperature of the oil bath reaches 130° C. within 20 to 30 minutes, and keep it warm for 1 hour. After cooling down to room temperature, 360 ml of acetone was added to precipitate Ag nanoparticles, which were then centrifuged to obtain Ag nanoparticles.

[0033] According to the analysis method described in Example 1, the degradation rate of X-3B in water by the photocatalytic fiber obtained in this example was measured and calculated.

Embodiment 3

[0035] This example is based on 0.3g of g-C 3 N 4 , AgNO with a mass ratio of 1:5 3 Prepared with the mixed solution of PVP, the difference between its concrete steps and Example 1 is:

[0036] AgNO 3 :PVP was mixed at a mass ratio of 1:5. First, dissolve 1.25g of PVP in 100ml of ethylene glycol, and add 0.25g of AgNO 3 Make it dissolve, control the temperature so that the temperature of the oil bath reaches 130° C. within 20 to 30 minutes, and keep it warm for 1 hour. After cooling down to room temperature, 360 ml of acetone was added to precipitate Ag nanoparticles, which were then centrifuged to obtain Ag nanoparticles.

[0037] According to the analysis method described in Example 1, the degradation rate of X-3B in water by the photocatalytic fiber obtained in this example was measured and calculated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com