Technology for synchronously recycling biomass and enabling chromium slag to be harmless by steel slag waste heat

A technology of biomass and resource utilization, applied to the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve the problems of effective utilization of less heat energy, avoid secondary heat pollution, improve fuel product quality, surface area The effect of reducing the amount of char

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

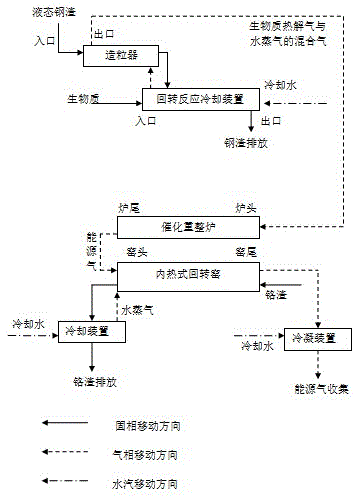

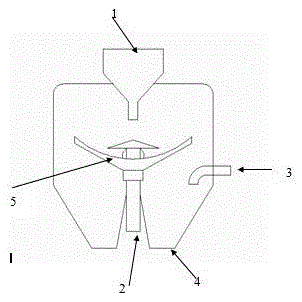

[0033] (1) Liquid steel slag at a temperature of 1500-1700°C is poured from the slag tank to the inlet of the granulator. After granulation, it enters the inlet of the rotary reaction cooling device from the outlet, mixes with biomass, and pyrolyzes the biomass. Then steel slag and biomass pyrolysis coke are transported to the outlet of the rotary reaction cooling device, and discharged after being cooled by cooling water; the continuous input mass ratio of cooling water for cooling steel slag to steel slag is 1:4; the continuous input mass ratio of biomass to steel slag 1:2;

[0034] (2) The cooling water in step (1) is fed from the outlet of the rotary reaction cooling device, sprayed onto the surface of the steel slag, heated and converted into water vapor; the water vapor then flows in the opposite direction with the steel slag and exchanges heat, and is transported to the inlet of the rotary reaction cooling device Mixed with biomass pyrolysis gas; the mixed gas is then s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com