Machining method used for thin-wall cavity type magnesium-lithium alloy part

A magnesium-lithium alloy and mechanical processing technology, which is applied in the field of mechanical processing of magnesium-lithium alloy parts, to achieve the effects of avoiding accidents, ensuring chip removal, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A machining method for thin-walled cavity-type magnesium-lithium alloy parts at least includes the following steps:

[0030] 1) Unload the bar;

[0031] 2) Car outer circle, drill, car deep hole;

[0032] 3) The shape of rough milled parts, leaving a margin of 2mm on one side;

[0033] 4) According to the requirements of the parts, the deep holes of step 2) are counted and milled;

[0034] 5) Heat the parts, first clean the parts with gasoline and place them in the air to dry thoroughly to ensure that there are no chips on the surface of the parts. Heat the parts in a constant temperature box to a temperature of 90°C for 3 hours, and then air-cool to room temperature;

[0035] 6) Semi-finish milling of the surface of the part, leave a fine milling allowance of 1mm on one side, and ensure that the vertical planes of the parts are perpendicular to each other at 0.05mm;

[0036] 7) Perform cryogenic treatment on the parts, clean up the small or dusty chips on the parts before installi...

Embodiment 2

[0041] A machining method for thin-walled cavity type magnesium-lithium alloy parts includes the following steps:

[0042] 1) Unload the bar;

[0043] 2) Turn the outer circle, drill and turn deep holes; during turning, the speed of the machine tool should be less than 400r / min, and the feed rate should be greater than 0.5mm; the material of the turning tool is cemented carbide or high-speed steel tool, and the back angle of the turning tool α=12~15°, rake angle γ=8~12°; when drilling deep holes, use a drill bit smaller than φ20mm for processing, withdraw the tool in time after each drilling depth of 2mm, and clean the cutting chips of the drill bit and feed again to avoid When drilling deep holes, it is easy to cause magnesium chips to accumulate and cause fire; during turning, use mineral oil coolant to cool down, and the cutting oil should have a low viscosity. To prevent corrosion of magnesium alloys, the free acid content of mineral oil should be less than 0.2% ;

[0044] 3) T...

Embodiment 3

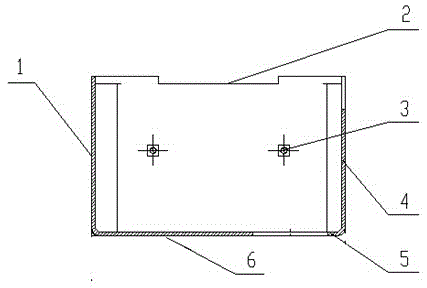

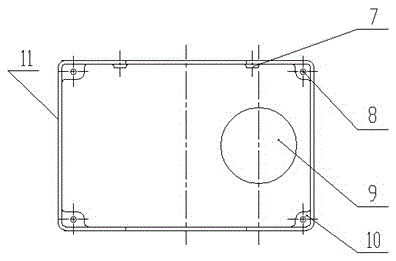

[0058] Take machining parts as an example, the material is magnesium-lithium alloy, and the part structure is as figure 1 and figure 2 As shown, the external dimension of the part is 39mm, the height of the part is 39mm, the length of the part 6 is 69mm, the width of the part 11 is 45mm, the peripheral wall thickness 4 is only 2.5mm, the bottom thickness 5 is 2mm, the end face has a gap 2 and the part bottom has 1 The diameter of the large holes 9 is Φ24mm, the size of 4 small holes 8 on the bosses 10 is Φ3mm×30mm (depth), the size of 2 threaded holes on the bosses 7 is M2-6H (through hole) .

[0059] From the analysis of the part structure, the part has a relatively large external size, the peripheral wall thickness is only 2.5mm, and the bottom thickness is 2mm. It is a typical thin-walled cavity part with poor structural rigidity and easy deformation; the ratio of the diameter of 4 small holes to the depth of the hole 10, it is a slender hole, it is easy to accumulate magnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com