Cutting fluid cleaning system and method

A cutting fluid and regeneration system technology, applied in chemical instruments and methods, special treatment targets, water/sludge/sewage treatment, etc. Allergy risk, avoid the generation of bacteria, improve the effect of environmental safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

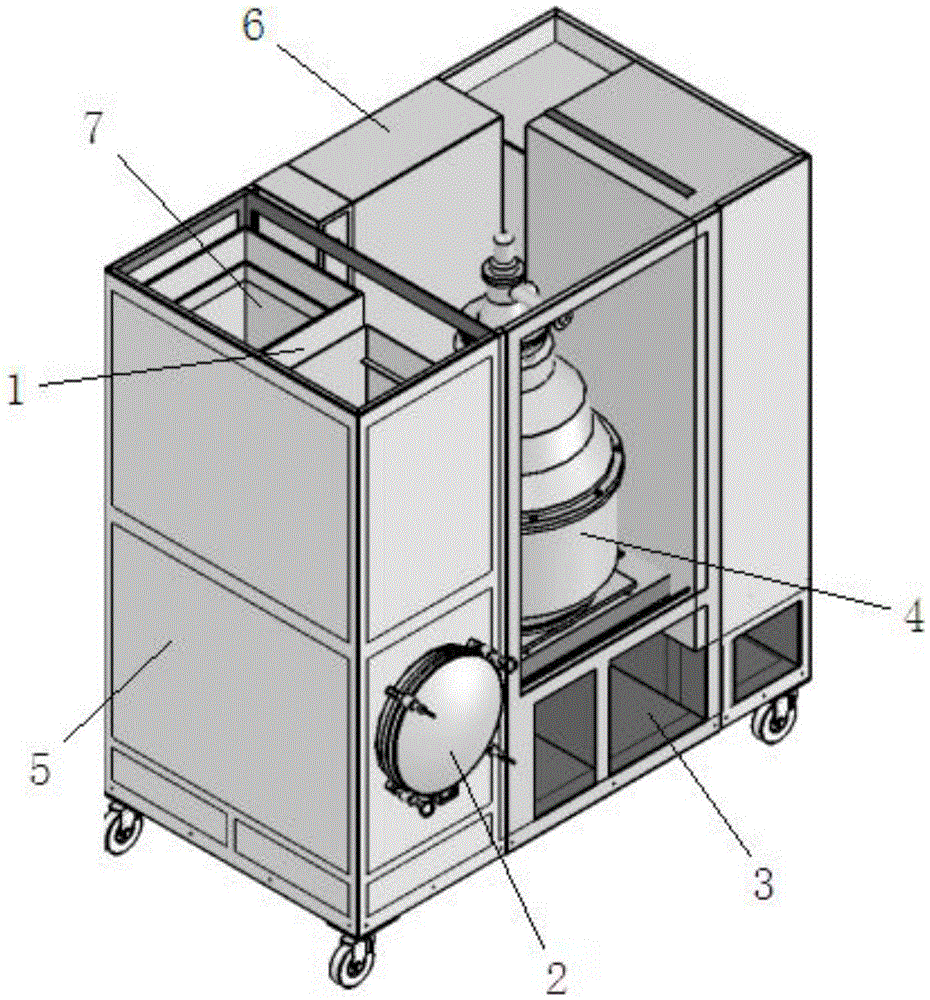

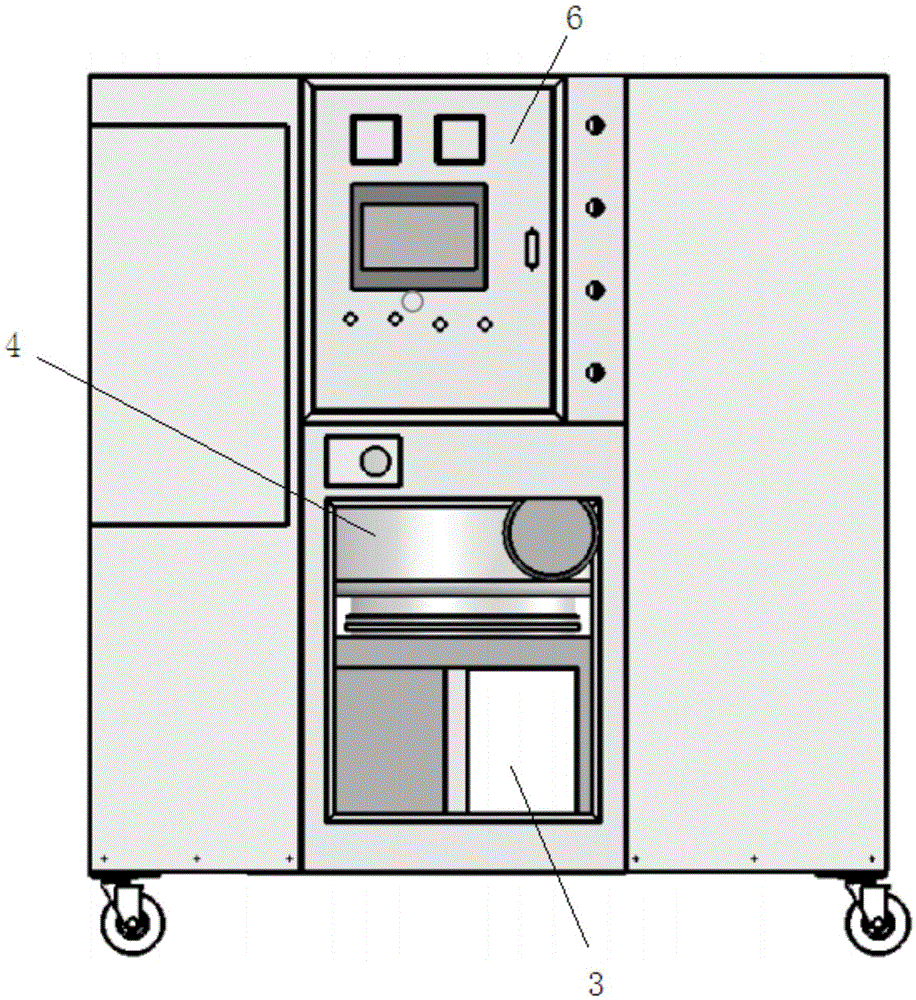

[0025] Such as figure 1 , figure 2 As shown, a cutting fluid cleaning system has a box, and the box is equipped with an intelligent centrifugal filtration system 4, a liquid pumping and separation system 2, a liquid storage and regeneration system 1, a waste oil and residue storage box 3, a sterilization system 5 and a control box 6. The control box 6 can fully control the operation of the equipment, including monitoring the pH value, concentration and remaining amount of the cutting fluid, and controlling the processing time, filtering and replenishing cooling fluid, etc.

[0026] The intelligent centrifugal filter system 4 is provided with multiple layers of filter papers with different ultra-precisions. The intelligent centrifugal filter system 4 is located in the middle of the box body, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com