Method for preparing petroleum resin in microreactor

A petroleum resin and microreactor technology, which is applied in the field of petroleum resin preparation in microreactors, can solve the problems of heat transfer in polymerization reaction, limit product synthesis rate and quality, affect product color and quality, and achieve reaction heat conduction Rapid, reduced space and energy consumption, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

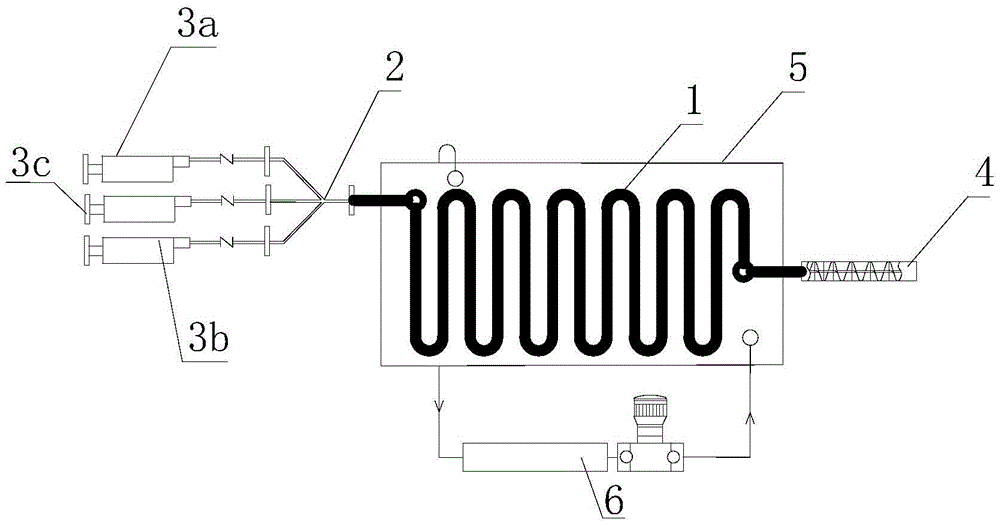

[0022] Microreactor provided by the invention, please refer to figure 1 , including a micro-reaction flow channel 1, the micro-reaction flow channel 1 is 1-15m long and has a cross-sectional area of 0.01-0.80mm 2 One end of the micro-reaction channel 1 is connected to the micro-reaction channel 2, and the micro-reaction channel 2 is connected to three parallel-set single-channel micro-injection pump A 3a, single-channel micro-injection pump B 3b, single-channel micro-injection pump C 3c, and micro-injection pump C 3c. The other end of the reaction channel 1 is connected to a single-screw extruder 4; the diameter of the screw of the single-screw extruder 4 is 90-300 mm.

[0023] The micro-reaction channel 1 is arranged in a wave shape, which reduces the occupied area, increases the reaction time of materials, and improves the product yield. For the convenience of heating, the micro-reaction flow channel 1 is placed in the constant temperature incubator 5, and the volume of t...

Embodiment 2

[0025] The method for preparing petroleum resin in a kind of microreactor provided by the present invention adopts the microreactor provided by embodiment 1, and concrete method is as follows:

[0026] 1) The heavy fraction of ethylene cracking by-product C9 is separated by rectification to separate the resin liquid fraction A with a distillation range of 130-150°C and the resin liquid fraction B with a distillation range of 150°C-170°C at a flow rate of 10ml / h. Channel micro-injection pump A and micro-injection pump B enter into micro-reaction channel 2;

[0027] 2) At the same time, the solution C containing the catalyst enters into the micro-reaction channel 2 through the micro-injection pump C at a flow rate of 10ml / h; the solution C is supplied by BF 3 : AlCl 3 : Toluene is mixed according to the mass ratio of 0.5:1.5:100;

[0028] 3) After being fully mixed in the micro-reaction channel 2, flow into the micro-reaction channel 1, and carry out a catalytic polymerization...

Embodiment 3

[0033] The method for preparing petroleum resin in a kind of microreactor provided by the present invention adopts the microreactor provided by embodiment 1, and concrete method is as follows:

[0034] 1) The heavy fraction of ethylene cracking by-product C9 is separated by rectification to separate the resin liquid fraction A with a distillation range of 130-150°C and the resin liquid fraction B with a distillation range of 170°C-190°C at a flow rate of 8ml / h, respectively through single Channel micro-injection pump A and micro-injection pump B enter into micro-reaction channel 2;

[0035] 2) At the same time, the solution C containing the catalyst enters into the micro-reaction channel 2 through the micro-injection pump C at a flow rate of 15ml / h; the solution C is supplied by BF 3 : AlCl 3 : Toluene is mixed according to the mass ratio of 1:1.5:100;

[0036] 3) After being fully mixed in the micro-reaction channel 2, flow into the micro-reaction channel 1, and carry out a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com