Preparation method and application of composite structure superhydrophilic chitosan aerogel under oil

A composite structure and chitosan technology, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., can solve problems such as high pollution and high cost, and achieve simple operation, controllable experimental parameters, and convenient secondary recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

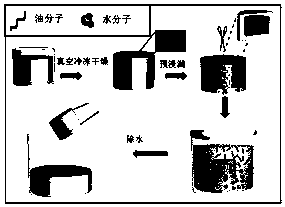

[0030] Specific implementation mode one: as figure 1 As shown, the present embodiment prepares superhydrophilic chitosan airgel under oil according to the following steps:

[0031] Step 1: Preparation of chitosan three-dimensional network airgel by ice template method

[0032] 1. Prepare chitosan solution (0.1~10wt %): Dissolve chitosan powder (0.1~10g, Mw=100~1000) in 100ml of acetic acid aqueous solution (0.5~5 wt %).

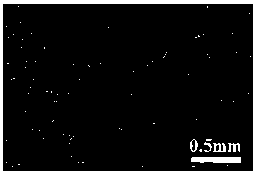

[0033] 2. Inject the chitosan solution into a plastic mold, seal it with plastic wrap, freeze it completely at -20~-40°C for 10~30h, take it out, put it in a freeze dryer, freeze dry it for 3~7 days, and get a block Chitosan airgel ( Figure 2-3 ).

[0034] The three-dimensional network chitosan airgel is formed by freezing water into ice crystals as templates and drying to remove them. The freeze-drying time and the concentration of acetic acid will play a decisive role in the hydrophilicity of chitosan and subsequent formation of hydrogel layer by chito...

specific Embodiment approach 2

[0039] Specific embodiment two: this embodiment prepares superhydrophilic chitosan airgel under oil according to the following steps:

[0040] Step 1: Preparation of chitosan three-dimensional network airgel by ice template method

[0041] Prepare chitosan solution (1 wt %): Dissolve chitosan powder (1 g, Mw=200~400) in 100 ml of acetic acid aqueous solution (1 wt %). The chitosan solution was injected into a plastic mold, sealed with a plastic wrap, completely frozen at -25°C for 15 hours, taken out, put into a freeze dryer, and freeze-dried for 6 days.

[0042] Step 2, pre-soaking the prepared chitosan airgel.

[0043] The prepared chitosan airgel was completely immersed in water, the soaking time was controlled to be 2s, and the thickness of the outer hydrogel layer was tested to be 1.5mm.

[0044] Step 3: Apply the composite structure chitosan in step 2 to absorb water in the oil-water mixture, the adsorption capacity is 88.21g / g, and the test separation efficiency can r...

specific Embodiment approach 3

[0046] Specific embodiment three: this embodiment prepares superhydrophilic chitosan airgel under oil according to the following steps:

[0047] Step 1: Preparation of chitosan three-dimensional network airgel by ice template method

[0048] Prepare chitosan solution (2 wt %): Dissolve chitosan powder (2 g, Mw=200~400) in 100 ml of acetic acid aqueous solution (2 wt %). The chitosan solution was injected into a plastic mold, sealed with a plastic wrap, completely frozen at -25°C for 15 hours, taken out, put into a freeze dryer, and freeze-dried for 6 days.

[0049] Step 2, pre-soaking the prepared chitosan airgel.

[0050] The prepared chitosan airgel was completely immersed in water, the soaking time was controlled to be 1s, and the thickness of the outer hydrogel layer was tested to be 1mm.

[0051] Step 3: Apply the composite structure chitosan in step 2 to absorb water in the oil-water mixture, the adsorption capacity is 105.32g / g, and the test separation efficiency can re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com