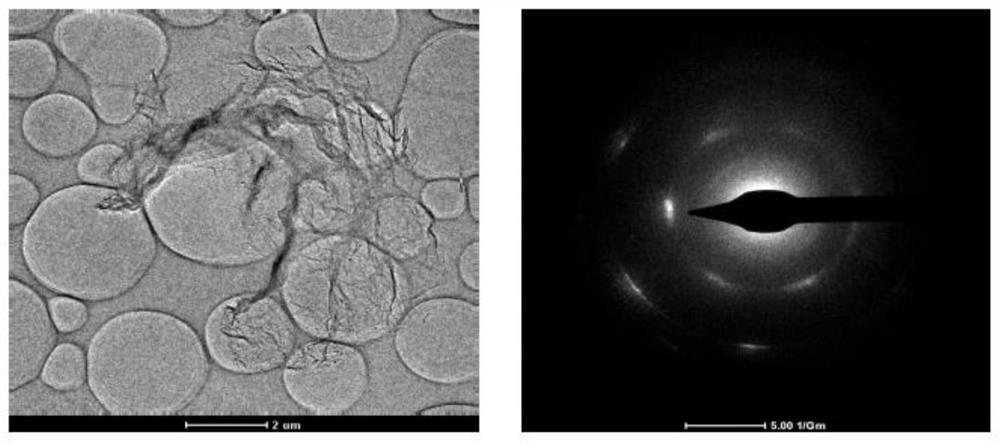

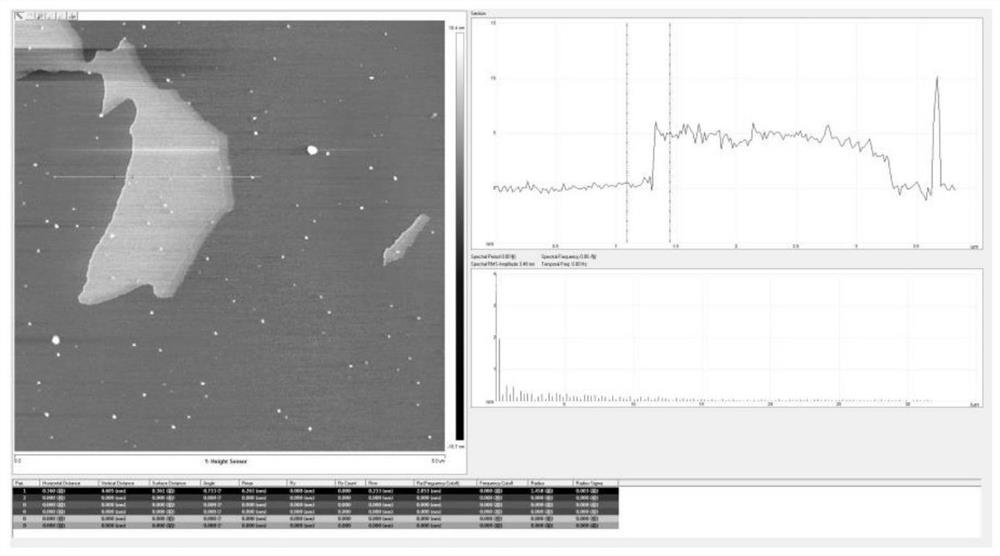

A kind of preparation method of ultra-thin graphene powder and its prepared product

A graphene powder and graphene technology, applied in the field of preparation of ultra-thin graphene powder, can solve the problems of complex process, incomplete peeling, low graphene yield, etc., and achieve a green and simple preparation method and simple and easy equipment and process. The effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method of ultra-thin graphene powder of the present embodiment, described method specifically comprises the following steps:

[0034] (1) Using a graphite rod as a working electrode, add a 5V DC voltage to the sodium sulfate electrolyte, electrolyze for 6 hours, then undergo solid-liquid separation, ultrasonic dispersion, washing, and drying to obtain a graphene precursor;

[0035] (2) Dissolving the above-mentioned graphene precursor in N-methylformamide, the proportioning of the graphene precursor and N-methylformamide is 10g / L, and the resulting solution is placed in an ultrasonic cleaning machine for ultrasonic 3h, The ultrasonic temperature is 30°C, the ultrasonic power is 500W, the solution after ultrasonic treatment is suction filtered, and the filtered solid is put into the autoclave;

[0036] (3) After the temperature in the autoclave reaches 25°C, pump carbon dioxide into the autoclave, and treat for 2 hours after the pressure in the auto...

Embodiment 2

[0040] A kind of preparation method of ultra-thin graphene powder of the present embodiment, described method specifically comprises the following steps:

[0041] (1) Using a graphite rod as a working electrode, add a 5V DC voltage to the sodium sulfate electrolyte, electrolyze for 8 hours, and then undergo solid-liquid separation, ultrasonic dispersion, washing, and drying to finally obtain a graphene precursor;

[0042] (2) The above-mentioned graphene precursor is dissolved in N, in N-dimethylformamide, the proportioning of graphene precursor and N, N-dimethylformamide is 40g / L, the gained solution is placed in ultrasonic Ultrasound in the cleaning machine for 2 hours, the ultrasonic temperature is 35 ° C, the ultrasonic power is 800 W, the solution after ultrasonic treatment is suction filtered, and the filtered solid is put into the autoclave;

[0043] (3) After the temperature in the autoclave reaches 25°C, pump carbon dioxide into the autoclave, and treat for 3 hours af...

Embodiment 3

[0047] A kind of preparation method of ultra-thin graphene powder of the present embodiment, described method specifically comprises the following steps:

[0048](1) Using a graphite rod as a working electrode, add a 6V DC voltage to the potassium sulfate electrolyte, electrolyze for 5 hours, then undergo solid-liquid separation, ultrasonic dispersion, washing, and drying to finally obtain a graphene precursor;

[0049] (2) Dissolve the above-mentioned graphene precursor in acetamide, the proportion of graphene precursor and acetamide is 30g / L, put the resulting solution in an ultrasonic cleaner for 4 hours, the ultrasonic temperature is 40°C, and the ultrasonic power 500W, suction filter the solution after ultrasonic treatment, filter out the solid and put it into the autoclave;

[0050] (3) After the temperature in the autoclave reaches 30°C, pump carbon dioxide into the autoclave, and treat for 4 hours after the pressure in the autoclave reaches 20 MPa;

[0051] (4) Decrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com