A heat storage pp resin-based composite shoe material and its preparation method

A resin-based, heat storage technology, applied in footwear, applications, clothing, etc., can solve the problems of lack of heat storage function, poor heat storage and warmth retention, etc. capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

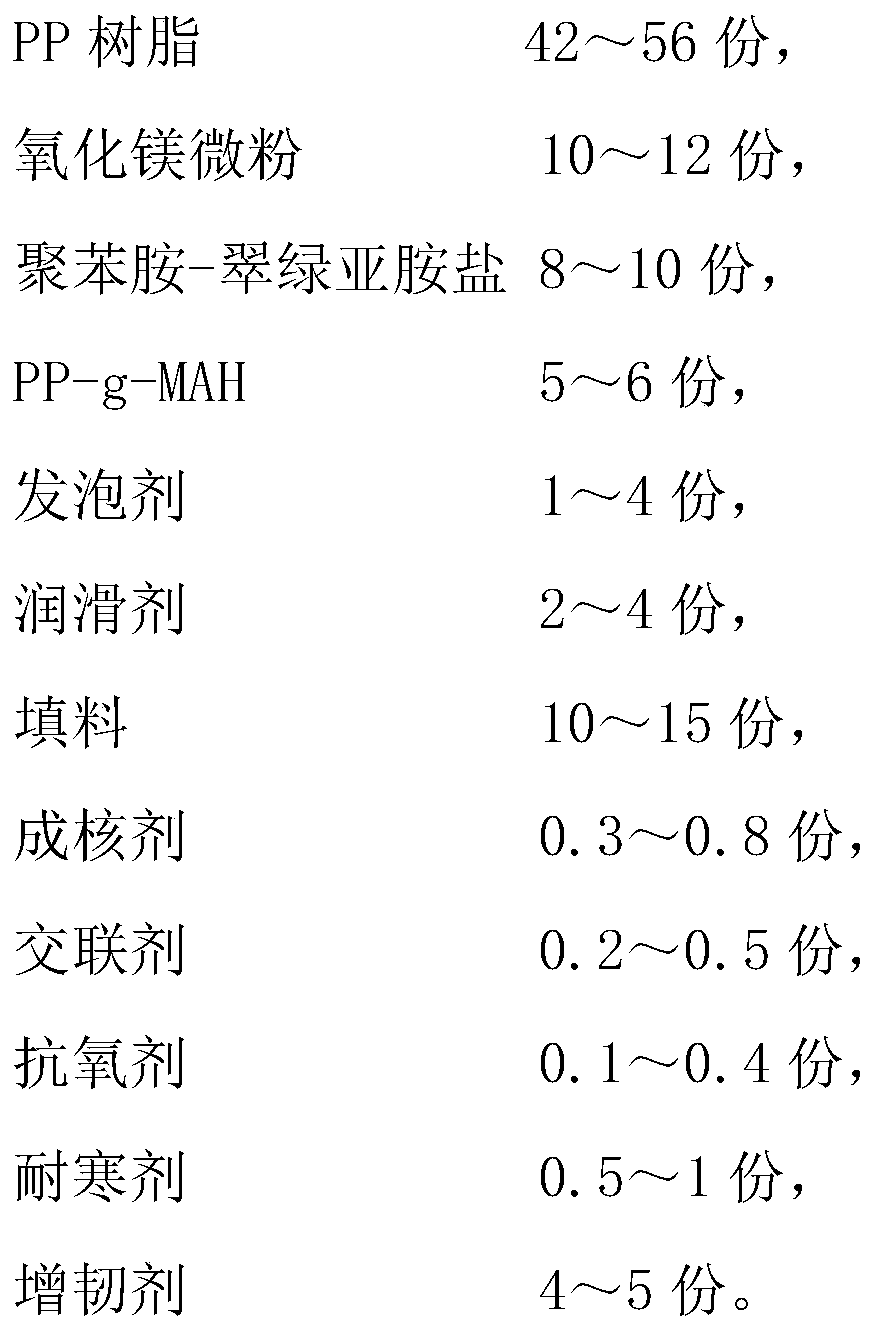

Method used

Image

Examples

Embodiment 1

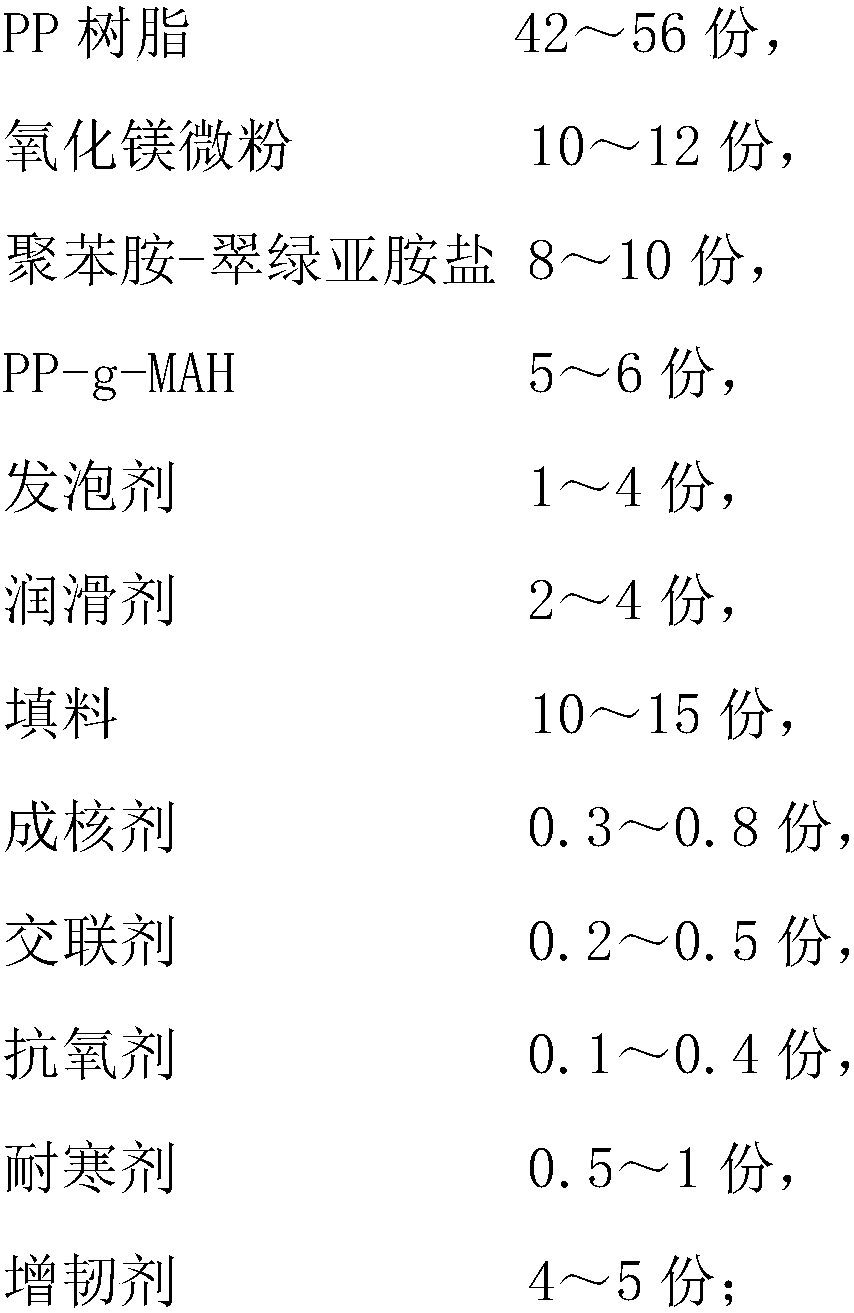

[0028] A thermal storage PP resin-based composite shoe material, made of the following components in parts by weight: 45 parts of PP resin, 10.5 parts of magnesium oxide micropowder, 9.5 parts of polyaniline-emeraldine salt, 5.5 parts of PP-g-MAH 4 parts, DIAD 4 parts, stearamide 2.5 parts, talc powder 14 parts, organophosphate nucleating agent 0.3 parts, dicumyl peroxide 0.3 parts, antioxidant 1010 0.2 parts, dioctyl azelate 0.7 parts copies, MBS 4.2 copies.

[0029] The steps of its preparation method are as follows:

[0030] (1) Dissolve magnesium oxide micropowder in deionized water, the volume ratio of magnesium oxide micropowder to deionized water is 1:3, after stirring for 2 hours to obtain a uniform magnesium oxide slurry, add glyceryl monostearate to the oxidation Stir in the magnesium slurry at 65°C for 3.5 hours, the mass ratio of glycerol monostearate to the magnesium oxide slurry is 1:9, after discharging, suction filter, wash, and dry in a vacuum oven at 100°C f...

Embodiment 2

[0034] A thermal storage PP resin-based composite shoe material, made of the following components in parts by weight: 55 parts of PP resin, 11 parts of magnesium oxide micropowder, 9 parts of polyaniline-emeraldine salt, 5.2 parts of PP-g-MAH 3 parts of DIAD, 2 parts of stearamide, 12 parts of mica powder, 0.5 parts of organophosphate nucleating agent, 0.4 parts of dicumyl peroxide, 0.3 parts of antioxidant 1010, 0.8 parts of dioctyl azelate copies, MBS 4 copies.

[0035] The steps of its preparation method are as follows:

[0036] (1) Dissolve magnesium oxide micropowder in deionized water, the volume ratio of magnesium oxide micropowder to deionized water is 1:3, after stirring for 2 hours to obtain a uniform magnesium oxide slurry, add glyceryl monostearate to the oxidation Stir in the magnesium slurry at 65°C for 3.5 hours, the mass ratio of glycerol monostearate to the magnesium oxide slurry is 1:9, after discharging, suction filter, wash, and dry in a vacuum oven at 100...

Embodiment 3

[0040] A thermal storage PP resin-based composite shoe material, made of the following components in parts by weight: 56 parts of PP resin, 11.5 parts of magnesium oxide micropowder, 10 parts of polyaniline-emeraldine salt, 5 parts of PP-g-MAH 3.5 parts of DIAD, 3.5 parts of stearamide, 10 parts of mica powder, 0.7 parts of organophosphate nucleating agent, 0.2 parts of dicumyl peroxide, 0.1 part of antioxidant 1010, 1 part of dioctyl azelate copies, MBS 4.5 copies.

[0041] The steps of its preparation method are as follows:

[0042] (1) Dissolve magnesium oxide micropowder in deionized water, the volume ratio of magnesium oxide micropowder to deionized water is 1:3, after stirring for 2 hours to obtain a uniform magnesium oxide slurry, add glyceryl monostearate to the oxidation Stir in the magnesium slurry at 65°C for 3.5 hours, the mass ratio of glycerol monostearate to the magnesium oxide slurry is 1:9, after discharging, suction filter, wash, and dry in a vacuum oven at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com