Halogen-free resin composition and application thereof

A resin composition and resin technology, applied in the field of laminates and printed circuit boards, prepregs, and halogen-free resin compositions, can solve the problems of bond failure, blistering, delamination or interlayer cracking, wood pulp paper fiber Reinforcement effect and poor interlayer adhesion can solve the problems of cracking and delamination and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

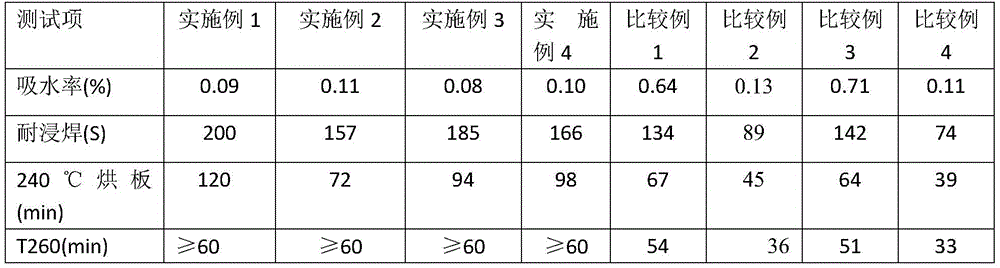

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in combination with specific embodiments.

[0027] A halogen-free resin composition according to the present invention comprises the following components in parts by solid weight: epoxy resin with large epoxy equivalent: 15 to 30 parts; epoxy resin with small epoxy equivalent: 20 to 55 parts ; Curing agent: 10 parts to 45 parts; Curing accelerator: 0.03 parts to 2.0 parts; Among them, the equivalent of epoxy resin with large epoxy equivalent is 300 (g / eq) to 800 (g / eq); small epoxy equivalent The equivalent weight of the epoxy resin is 170 (g / eq)-280 (g / eq); the functionality of the epoxy resin is 2-4.

[0028] Under the condition of certain functionality, the epoxy resin with small equivalent weight has small molecular weight and good permeability, and it is easy to squeeze and penetrate into the paper fibers from the pores of the paper under high temperature and high pressure conditions. The paper-based fiber is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com