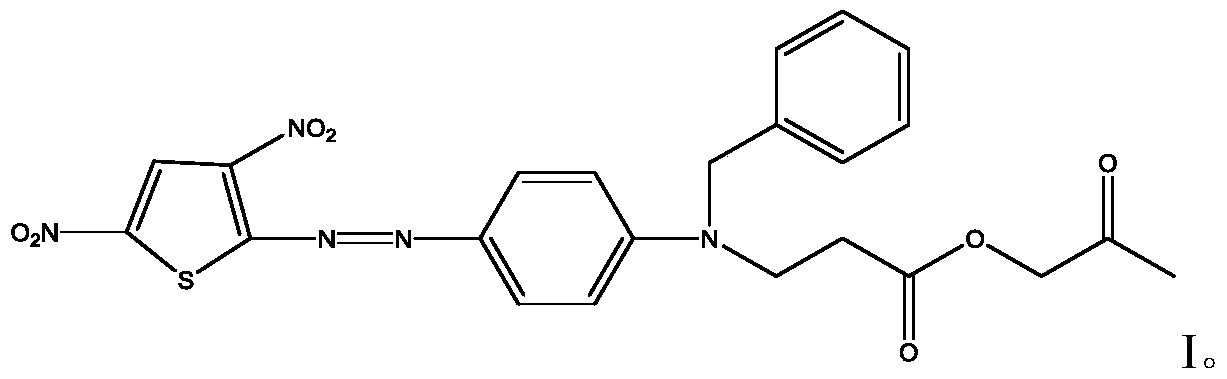

A kind of disperse dye monomer compound and its preparation method and application

A technology of disperse dyes and compounds, which is applied in the field of non-ionic dyes, can solve the problems of lack of wide applicability, and achieve the effects of high white fastness, good reproducibility, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of the esterified product shown in formula (II):

[0026]

[0027] Mix 37g of aniline, 28.8g of acrylic acid, and 100g of water, stir at 90°C for 20 hours, lower the temperature, add 200g of methanol, stir at 0°C for 12 hours, and filter to obtain the compound represented by formula (V).

[0028] Mix 16g of the compound represented by formula (V), 150g of water, 11g of soda ash, and 20g of benzyl chloride, stir, add 2g of potassium iodide at 80°C, react for 12 hours, cool down, add 100g of methanol, stir at 0°C for 12 hours, filter, The compound represented by formula (IV) is obtained.

[0029] Mix 25.5g of the compound represented by formula (IV) with 100g of DMF, 11g of soda ash, and 14g of bromoacetone, heat up to 60°C, add 1g of potassium iodide, stir and react for 12 hours, cool down to 40°C, add 200g of water, filter to obtain the formula ( II) The esterified product shown.

[0030] The preparation of diazide (III):

[0031]

[0032] Mix 4...

Embodiment 2

[0037] Mix 40 g of the compound of formula (I) and 60 g of MF with water, grind and disperse with a grinder, and then spray dry to obtain a blue dye.

Embodiment 3

[0039] Take 2.0g of the disperse dyes prepared in Example 2, and use water to make disperse dye suspensions with a concentration of 2g / L, mix 2ml with 8ml of water, adjust the pH of the dyeing bath to 5 with acetic acid, and then heat up to 60°C , and at the same time put 2g of the fiber materials shown in the table below for high-temperature and high-pressure dyeing, heat up to 130°C within 30 minutes, keep warm for 30 minutes, cool down, and take samples. Check the infection rate. And test the color fastness to rubbing, color fastness to washing, spelling white fastness and color fastness to sublimation of embodiment 2 respectively according to the relevant provisions of the national standard.

[0040] As shown in the following table, the disperse dyes prepared by using the compound of the present invention are significantly better than the prior art in washing fastness, rubbing fastness and spelling white fastness.

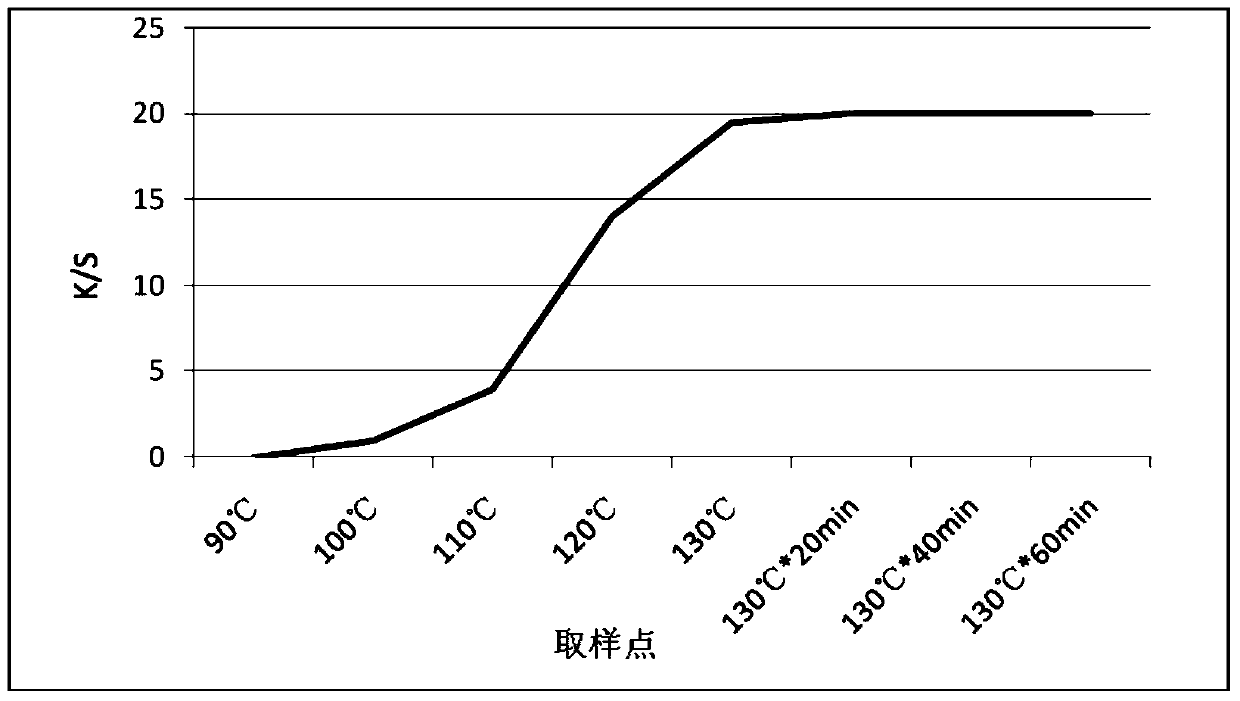

[0041] Such as figure 1 As shown, the dye of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com