Method for preparing gelatin by utilizing pigskin as raw material and preparation method

A technology for pigskin and gelatin, applied in the field of agricultural product processing, can solve the problems of poor gelatin decolorization effect, complicated preparation steps, poor gel properties, etc., achieves good application prospects, good gel properties, and improves the removal of residual oil and impurities. The effect of protein efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

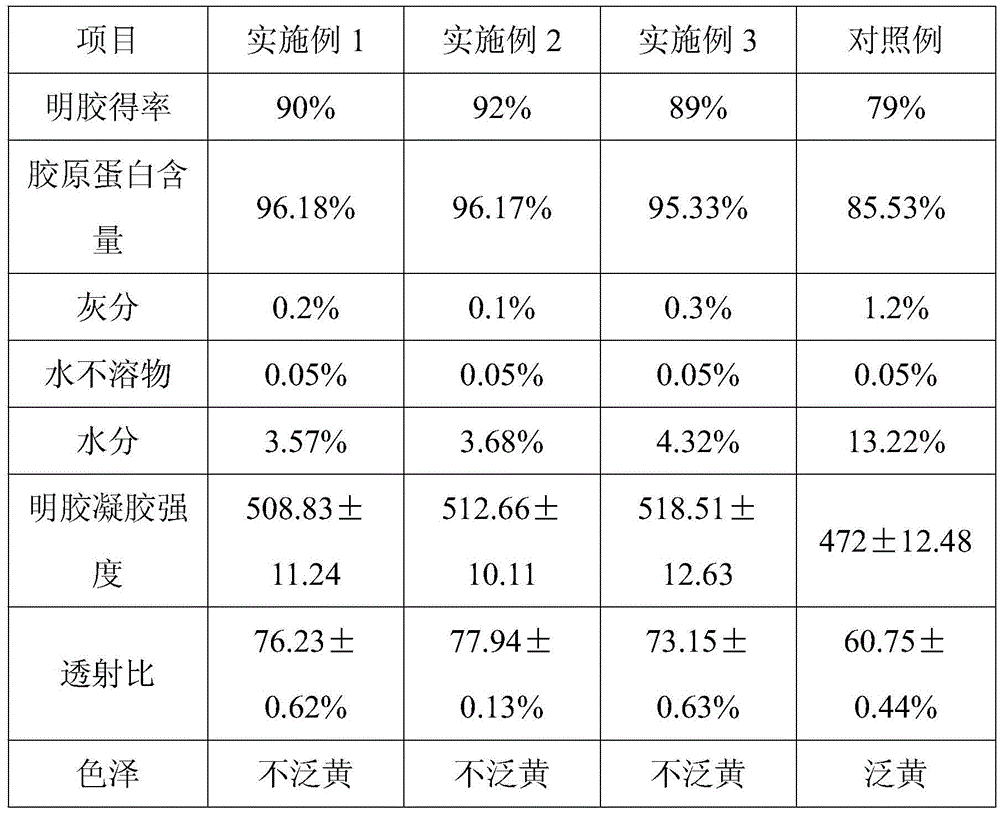

Examples

Embodiment 1

[0027] A method for preparing gelatin with pigskin as a raw material, the specific steps are as follows:

[0028] 1) Pigskin pretreatment: clean the pigskin, depilate, cut into small pieces of 3×3 mm, soak in 8% salt water for 2 hours, and wash with water;

[0029] 2) Pressurized acidification: use ethyl acetate as a solvent, submerge the pretreated pigskin, add phosphoric acid with a concentration of 10%, adjust the pH to 3-4, pressurize at 15 MPa, and pressurize for 2 hours;

[0030] 3) Pressurized alkali washing: the solution obtained in step 2) is concentrated under reduced pressure and washed with water, adding deionized water twice the weight of pigskin, and using triethylamine to adjust the solution obtained in step 2) so that its pH is 6 -7, pressurization pressure is 5MPa, pressurization time is 5h;

[0031] 4) Heating: Concentrate the solution obtained in step 4) under reduced pressure and rinse with water three times, add hydrogen peroxide 0.1 times the weight of p...

Embodiment 2

[0034] 1) Pigskin pretreatment: clean the pigskin, depilate, cut into 4×4mm small pieces, soak in 9% salt water for 4 hours, and wash with water;

[0035] 2) Pressurized acidification: use ethyl acetate as a solvent, submerge the pretreated pigskin, add phosphoric acid with a concentration of 10%, adjust the pH to 3-4, pressurize at 15 MPa, and pressurize for 2 hours;

[0036] 3) Pressurized alkali washing: the solution obtained in step 2) is concentrated under reduced pressure and washed with water, adding deionized water twice the weight of pigskin, and using triethylamine to adjust the solution obtained in step 2) so that its pH is 6 -7, pressurization pressure is 5MPa, pressurization time is 5h;

[0037] 4) Heating: Concentrate the solution obtained in step 4) under reduced pressure and rinse it with water three times, add hydrogen peroxide 0.2 times the weight of pigskin and deionized water 5 times the weight of pigskin, and heat at 40°C for 10 hours to obtain a gelatin ...

Embodiment 3

[0040] 1) Pigskin pretreatment: clean the pigskin, depilate, cut into small pieces of 5×5 mm, soak in 10% salt water for 5 hours, and wash with water;

[0041] 2) Pressurized acidification: use ethyl acetate as a solvent, submerge the pretreated pigskin, add phosphoric acid with a concentration of 10%, adjust the pH to 3-4, pressurize at 15 MPa, and pressurize for 2 hours;

[0042] 3) Pressurized alkali washing: the solution obtained in step 2) is concentrated under reduced pressure and washed with water, adding deionized water twice the weight of pigskin, and using triethylamine to adjust the solution obtained in step 2) so that its pH is 6 -7, pressurization pressure is 5MPa, pressurization time is 35h;

[0043] 4) Heating: Concentrate the solution obtained in step 4) under reduced pressure and rinse it with water three times, add hydrogen peroxide 0.15 times the weight of pigskin and deionized water 5 times the weight of pigskin, and heat at 40°C for 5 hours to obtain a ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com