A kind of preparation technology of acrylate adhesive and product thereof

A technology of acrylate and butyl acrylate, used in ester copolymer adhesives, adhesive types, conductive adhesives, etc., to achieve the effect of low total carbon content, excellent performance, and optimized process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

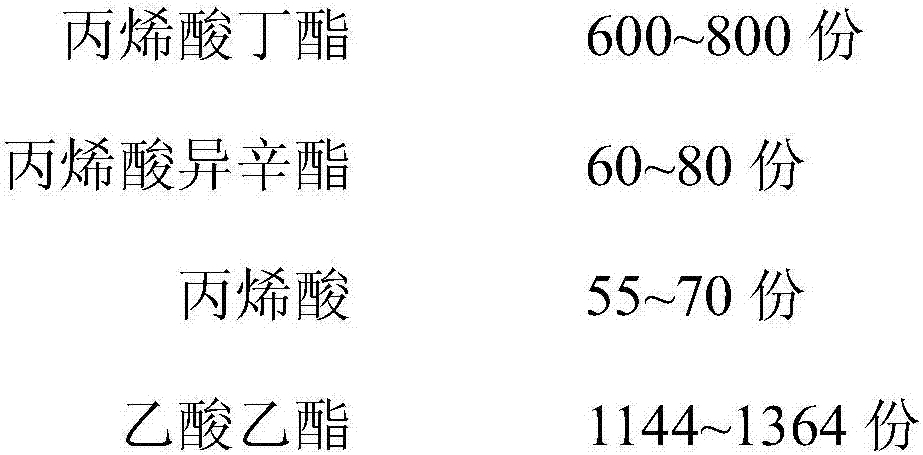

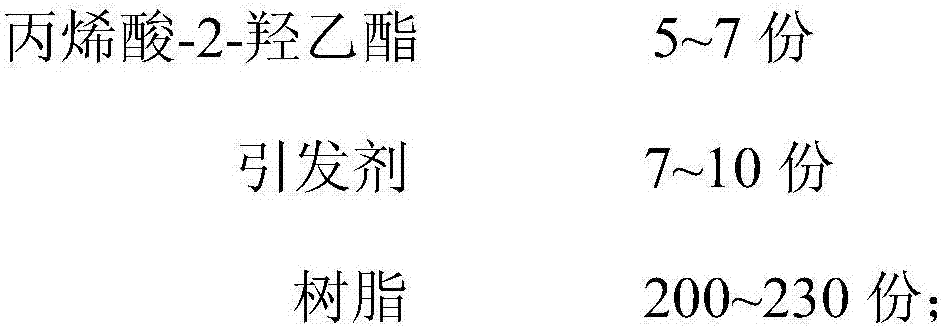

[0020] A kind of acrylate adhesive preparation technology, comprises the following steps:

[0021] a. Get the following raw materials by weight: 600 parts of butyl acrylate; 60 parts of isooctyl acrylate; 55 parts of acrylic acid; 1144 parts of ethyl acetate; 5 parts of 2-hydroxyethyl acrylate; 7 parts of AIBN; 200 parts of rosin resin;

[0022] b. Add 400 parts of butyl acrylate, 60 parts of isooctyl acrylate and 500 parts of ethyl acetate into the reaction kettle, and stir at 60-65°C for 1 hour;

[0023] c. Take 40 parts of acrylic acid and 4 parts of 2-hydroxyethyl acrylate into the reaction kettle in step b, and stir at 60-65°C for 0.5 hours;

[0024] d. Add 200 parts of butyl acrylate, 100 parts of ethyl acetate, 15 parts of acrylic acid, and 1 part of 2-hydroxyethyl acrylate into the reaction kettle in step c, and stir at 60-65°C for 1 hour;

[0025] e. Take 1.1 parts, 0.6 parts, 0.6 parts, 03 parts, 0.4 parts, and 4 parts of AIBN respectively, and take 10 parts, 5 part...

Embodiment 2

[0028] A kind of acrylate adhesive preparation technology, comprises the following steps:

[0029] a. Get the following raw materials by weight ratio: 800 parts of butyl acrylate; 80 parts of isooctyl acrylate; 70 parts of acrylic acid; 1364 parts of ethyl acetate; 7 parts of 2-hydroxyethyl acrylate; 10 parts of AIBN; 230 parts of rosin resin; 1.3 parts of conductive powder;

[0030] b. Add 500 parts of butyl acrylate, 80 parts of isooctyl acrylate, and 600 parts of ethyl acetate into the reaction kettle, and stir at 65-75°C for 1 hour;

[0031] c. Take 50 parts of acrylic acid and 5 parts of 2-hydroxyethyl acrylate into the reaction kettle in step b, and stir at 65-75°C for 0.5 hours;

[0032] d. Add 300 parts of butyl acrylate, 120 parts of ethyl acetate, 20 parts of acrylic acid, and 2 parts of 2-hydroxyethyl acrylate into the reaction kettle in step c, and stir at 65-75°C for 1 hour;

[0033] e. Take 1.9 parts, 0.8 parts, 0.8 parts, 0.4 parts, 0.5 parts, and 5.6 parts of...

Embodiment 3

[0037] A kind of acrylate adhesive preparation technology, comprises the following steps:

[0038] a. Get the following raw materials by weight ratio: 750 parts of butyl acrylate; 70 parts of isooctyl acrylate; 65 parts of acrylic acid; 1294 parts of ethyl acetate; 6 parts of 2-hydroxyethyl acrylate; 9 parts of AIBN; 200 parts of rosin resin;

[0039] b. Add 450 parts of butyl acrylate, 70 parts of isooctyl acrylate, and 550 parts of ethyl acetate into the reaction kettle, and stir at 65-75°C for 1 hour;

[0040] c. Add 45 parts of acrylic acid and 4.5 parts of 2-hydroxyethyl acrylate to the reaction kettle in step b, and stir at 65-75°C for 0.5 hours;

[0041] d. Add 300 parts of butyl acrylate, 150 parts of ethyl acetate, 20 parts of acrylic acid, and 1.5 parts of 2-hydroxyethyl acrylate into the reaction kettle in step c, and stir at 65-75°C for 1 hour;

[0042] e. Take 1.8 parts, 0.7 parts, 0.8 parts, 0.6 parts, 0.6 parts, and 4.5 parts of AIBN respectively, and take 10 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com