Method for comprehensively recovering copper and cobalt from copper cobalt oxide ore

A technology for copper oxide and copper recovery, which is applied in the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of low cobalt recovery rate, affecting sedimentation and extraction, and large consumption of chemicals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

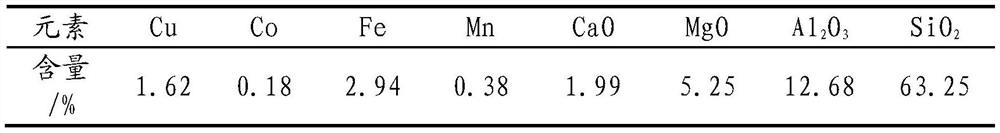

[0033] In this example, a copper-cobalt oxide mine in China was used, and the analysis results of the main elements are shown in Table 1.

[0034] Table 1 Analysis results of main elements of a copper-cobalt oxide ore in China

[0035]

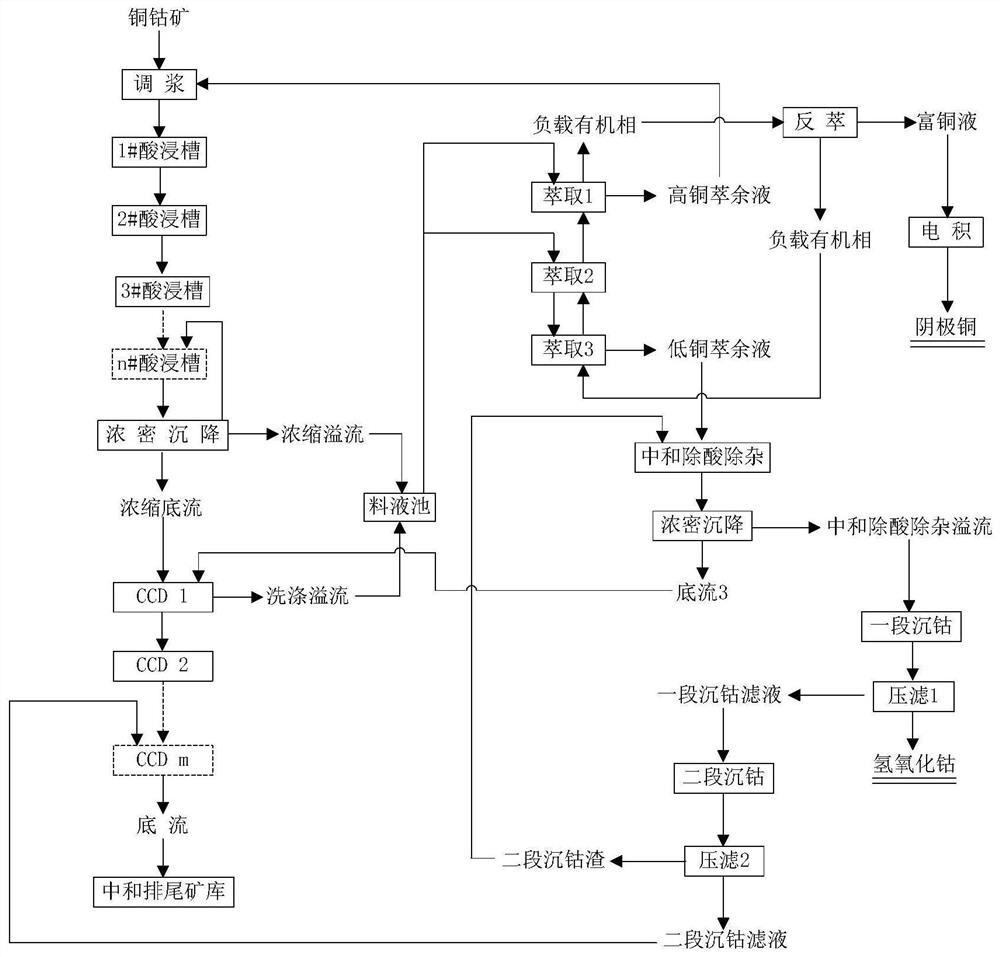

[0036] This embodiment provides a method for the comprehensive recovery of copper and cobalt from copper oxide cobalt ore, and the above-mentioned copper oxide cobalt ore is processed, such as figure 1 As shown, the specific process is as follows:

[0037] S1. Slurry: finely grind the copper-cobalt oxide ore to a particle size of -74 μm and account for 70%, then add it to the slurry tank, and process industrial water into the slurry tank to adjust the copper-cobalt oxide ore to the pulp mass percentage concentration Add concentrated sulfuric acid to adjust the pH value of the pulp to 1.0. At this time, the concentrated sulfuric acid exothermicly heats the pulp to 80°C, and finally adds chalcocite to adjust the oxidation-reduction potential...

Embodiment 2

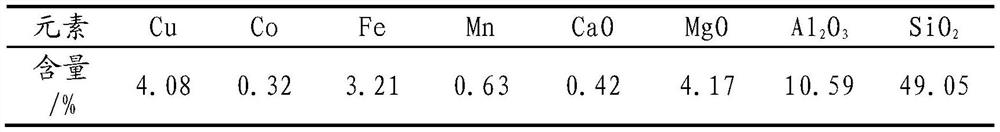

[0047] In this example, a copper-cobalt oxide ore in the Democratic Republic of the Congo was used, and the analysis results of the main elements are shown in Table 2.

[0048] Table 2 Analysis results of main elements of a copper-cobalt oxide ore in Congo (Kinshasa)

[0049]

[0050] In this embodiment, a method for comprehensively recovering copper and cobalt from copper-cobalt oxide ore is used to process the above-mentioned copper-cobalt oxide ore, such as figure 1 As shown, the specific process is as follows:

[0051] S1. Slurry: finely grind the above-mentioned copper-cobalt oxide ore until the particle size is -74μm, accounting for 75%, and then add it to the slurry tank, and adjust the copper-cobalt oxide ore to the mass percentage of the slurry by processing industrial water into the slurry tank The concentration is 55%, add concentrated sulfuric acid to adjust the pH value of the pulp to 1.2, at this time, the concentrated sulfuric acid exothermicly heats the pul...

Embodiment 3

[0061] In this example, a copper-cobalt oxide ore in Zambia was used, and the analysis results of the main elements are shown in Table 3.

[0062] Table 3 Analysis results of main elements of a copper-cobalt oxide ore in Zambia

[0063]

[0064] The present invention provides a kind of method of copper and cobalt comprehensive recovery copper and cobalt oxide ore, above-mentioned copper oxide cobalt ore is processed, such as figure 1 As shown, the specific process is as follows:

[0065] S1. Pulp mixing: finely grind the above-mentioned copper-cobalt oxide ore until the particle size is -74 μm, accounting for 80%, and then add it to the slurry mixing tank, and adjust the copper-cobalt oxide ore to the mass percentage of the slurry by processing industrial water into the slurry mixing tank The concentration is 55%, add concentrated sulfuric acid to adjust the pH value of the pulp to 1.5, at this time, the concentrated sulfuric acid exothermicly heats the pulp to 65°C, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com