Preparing method of aluminum alloy base material for electronic product shell

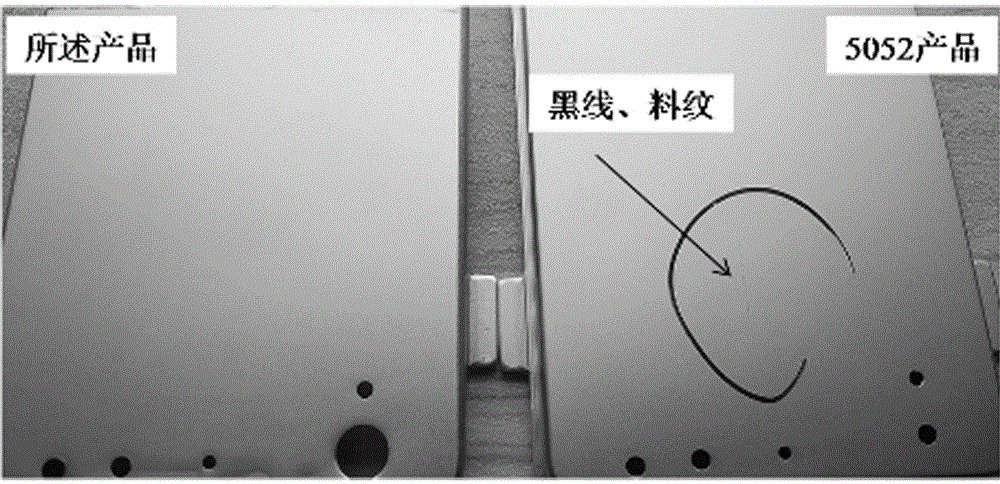

An aluminum alloy base and electronic product technology, applied in the field of aluminum alloy base material preparation, can solve problems such as the occurrence of material lines, and achieve the effects of good effect, uniform internal metallographic structure and elimination of color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

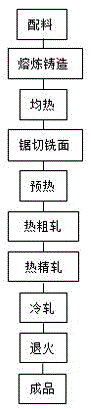

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing an aluminum alloy base material for an electronic product casing. The preparation steps are: put pure aluminum, pure zinc, AlCu50 alloy and AlZr5 alloy into a melting furnace for melting at a melting temperature of 720-770°C, then put pure magnesium into it, and put it into When the temperature is controlled at 750-770°C, it is then transferred to a holding furnace at 710-730°C for heat preservation, and refined by introducing chlorine and argon for 1 hour, standing for 1 hour, and then passing chlorine and argon for refining for 1 hour, standing for 1 hour, and turning to The on-line degassing and slag removal device is installed. During the on-line degassing, the volume ratio of chlorine gas is 2-5%, and the grain refiner is added on-line. Finally, a 40-mesh ceramic filter plate is used to remove the slag, and an ingot with a uniform structure is cast. The casting process described above is a semi-continuous casting method.

[0030] The raw mate...

Embodiment 2

[0039] A method for preparing an aluminum alloy base material for an electronic product casing. The preparation steps are: putting pure aluminum, pure zinc, AlCu50 alloy and AlZr5 alloy into a melting furnace for melting at a melting temperature of 720-770°C, and then putting the alloy and pure magnesium into , the temperature is controlled at 750-770°C when put in, and then transferred to the holding furnace at 710-730°C for heat preservation, and refined with chlorine and argon for 2 hours, and left for 2 hours, then refined with chlorine and argon for 2 hours, and left for 2 hours , transferred to the online degassing and slag removal device, when the online degassing, the volume ratio of chlorine gas is 2-5%, the grain refiner is added online, and finally the slag is removed by using a 50-mesh ceramic filter plate to cast an ingot with uniform structure , the casting process is a semi-continuous casting method.

[0040] The raw materials are 99.85% aluminum ingots, 99.92% ...

Embodiment 3

[0049] Cold rolling to a thickness of 2.5mm is annealed in the continuous annealing furnace and the chamber annealing furnace respectively in the air cushion furnace to form O state. The product properties are shown in Table 1. The coils annealed by air-cushion continuous annealing in the present invention have relatively small yield strength and high plasticity, which is beneficial to its subsequent deep drawing processing; The material has better comprehensive performance and better surface quality.

[0050] Table 1 Performance of products annealed into O state in hovering furnace continuous annealing furnace and box annealing furnace

[0051] Annealing method

[0052] Note: R p0.2 is the yield strength, R m is the tensile strength, A 50 is the elongation rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com