Medium temperature pitch mixture batching plant and method for preparing mixture by utilizing batching plant

An asphalt mixture and mixing building technology, which is applied to roads, road repairs, roads, etc., can solve the problems of the health of pollution discharge maintenance operators, the small maintenance usage, and the small scale of repair works, and reduce the phenomenon of low-level repeated maintenance. , the effect of reducing pollutant emissions and improving the quality of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

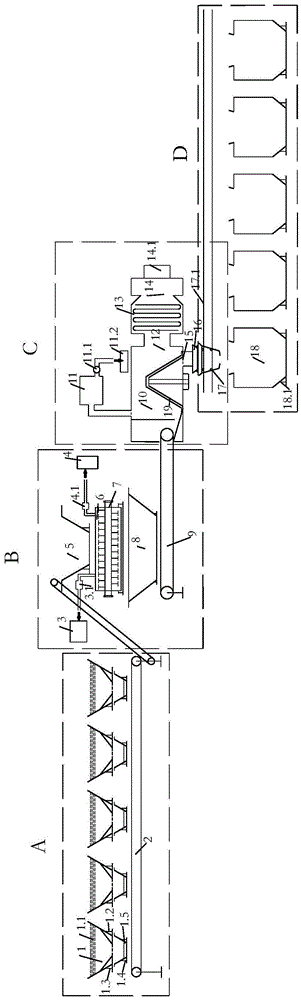

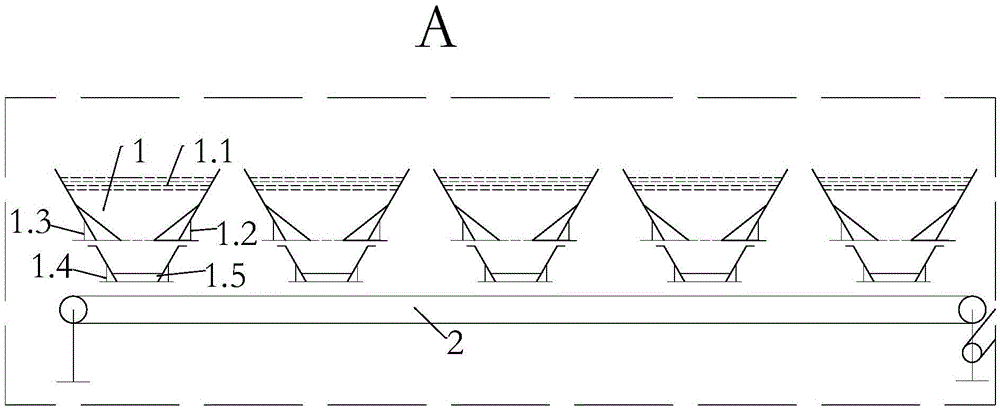

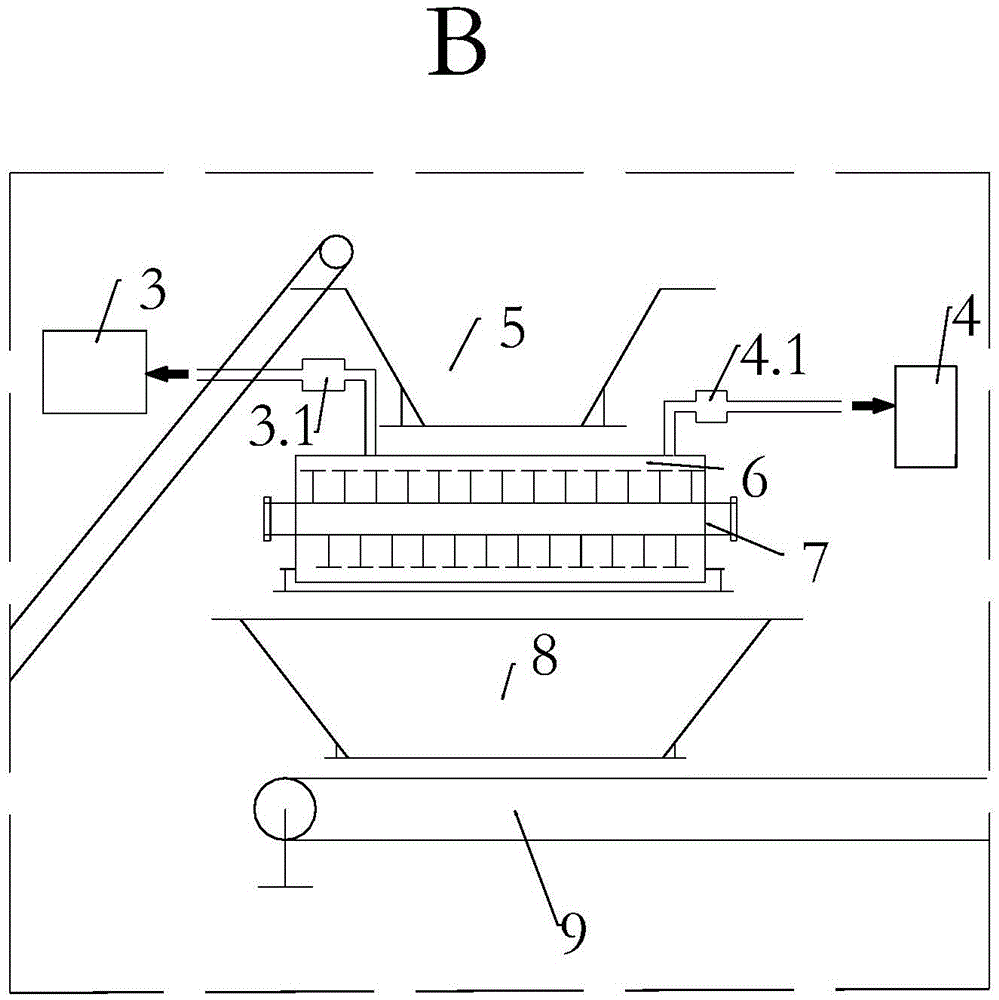

[0044] The equipment and process of the present invention will be further described in detail below in conjunction with specific examples.

[0045] The present invention designs a medium-temperature asphalt mixing plant, which uses modified medium-temperature asphalt with high solid content (solid content can reach more than 75%).

[0046] The high-solid-content modified medium-temperature asphalt mixture consists of the following components in parts by mass: 75-82 parts of base asphalt, 3-7 parts of medium-temperature modifier, and 11-22 parts of water.

[0047] Described middle temperature modifier is made up of following components by mass parts:

[0048] 5-10 parts of 18 / 16 tertiary amine;

[0049] 5 to 12 parts of cationic additives, wherein the cationic additives are selected from 3-chloro-2-hydroxypropyl-trimethylammonium chloride and trimethyldodecylammonium chloride;

[0050] 1 to 5 parts of methanol;

[0051] 40-50 parts of emulsifying agent, described emulsifying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com