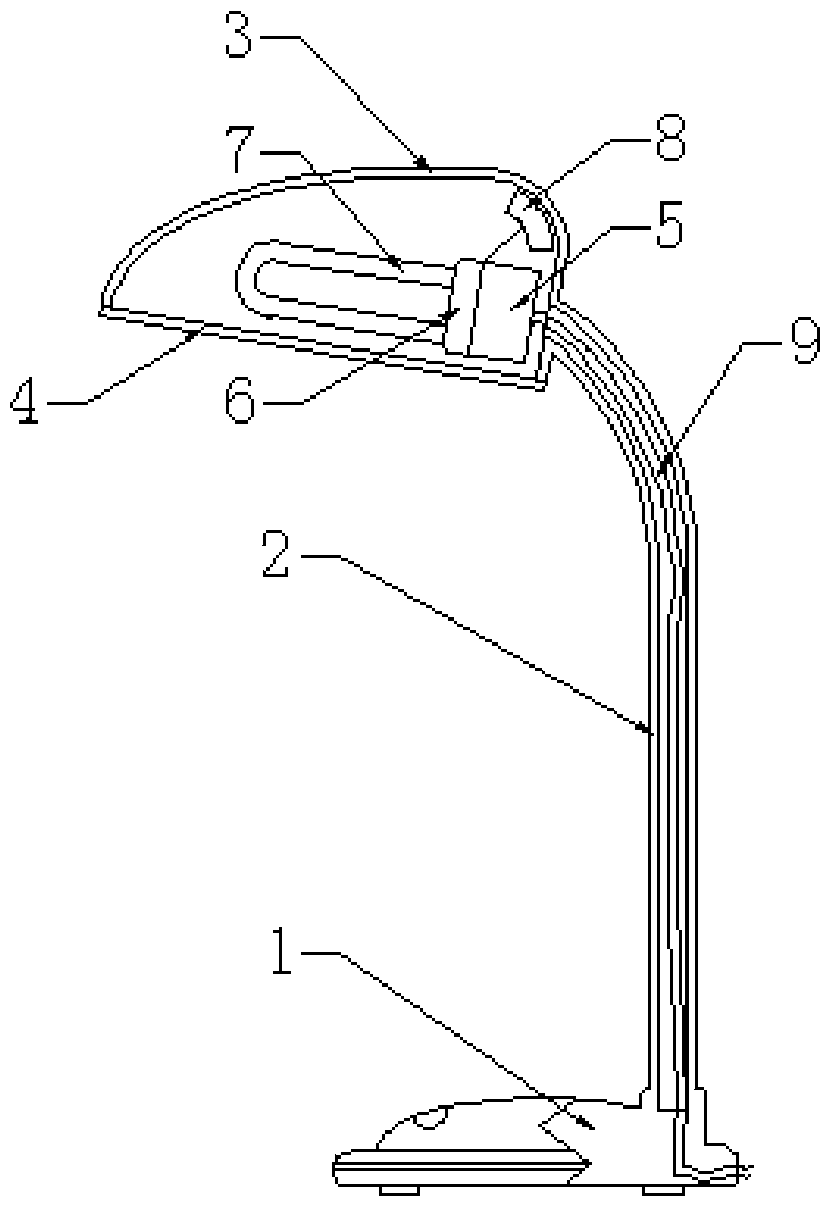

A kind of anti-radiation table lamp

A technology for anti-radiation and table lamps, applied in the field of lighting, can solve the problems of high radiation and short service life of table lamps, and achieve the effects of reducing electromagnetic radiation, good electrical and thermal conductivity, and prolonging the luminous life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

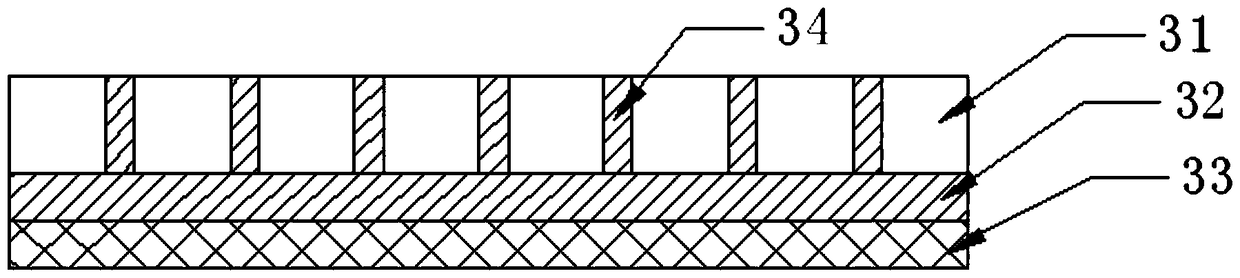

[0024] Such as figure 2 As shown, the lampshade rear cover 3 is mainly composed of an insulating base 31 , a heat absorbing layer 32 , a shielding layer 33 , and a heat conducting column 34 . Its preparation method is as follows: (1) inject heat-conducting column 34 on insulating substrate 31; , 0.4wt% manganese dioxide, 0.12wt% nano-nickel powder, 0.12wt% nano-aluminum powder, 0.08wt% nano-tin powder, and 0.06wt% solid sodium silicate are mixed evenly to form a mixed powder, and then the mixed powder is added to the ring In the butanol of epoxy resin, continue to stir until the mixture is uniform to form a mixed solution; (3) spray the mixed solution in step (2) on the insulating substrate 31 after step (1), and put it into a 100 ° C Curing in an oven for 3 hours, taking it out and letting it cool to make a heat-absorbing layer 32 with a thickness of 200 μm; (4) using nano-conductive copper paste to print a layer of copper on the heat-absorbing layer 32 prepared in step (3)...

Embodiment 2

[0026] In the present embodiment, the preparation method of the lampshade lampshade back cover 3 is as follows: (1) injecting the thermal conduction column 34 on the insulating base 31; (2) dissolving 4wt% epoxy resin in 59.38wt% butanol at room temperature, and simultaneously Mix 35wt% carbon black, 1wt% graphene, 0.3wt% manganese dioxide, 0.1wt% nano-nickel powder, 0.1wt% nano-aluminum powder, 0.07wt% nano-tin powder, 0.05wt% solid sodium silicate to form Mix the powder, then add the mixed powder to the butanol containing epoxy resin, continue to stir until the mixture is uniform, and form a mixed slurry; (3) spray the mixed slurry in step (2) on the treated surface of step (1) On the insulating substrate 31, put it into an oven at 100° C. to cure for 2.5 hours, take it out and let it cool, and make a heat-absorbing layer 32 with a thickness of 200 μm; (4) use nano-conductive copper paste to prepare the heat-absorbing layer in step (3) 32 is printed with a layer of copper me...

Embodiment 3

[0028]In the present embodiment, the preparation method of the lampshade lampshade rear cover 3 is as follows: (1) injecting the thermal conduction column 34 on the insulating base 31; (2) dissolving 3wt% epoxy resin in 66.05wt% butanol at room temperature, and simultaneously Mix 30wt% carbon black, 0.5wt% graphene, 0.2wt% manganese dioxide, 0.08wt% nanometer nickel powder, 0.08wt% nanometer aluminum powder, 0.06wt% nanometer tin powder, 0.03wt% solid sodium silicate, Form a mixed powder, then add the mixed powder to butanol containing epoxy resin, continue to stir until the mixture is uniform, and form a mixed slurry; (3) spray the mixed slurry in step (2) after step (1) treatment On the insulating substrate 31, put it into an oven at 120° C. to cure for 2 hours, take it out and let it cool, and make a heat absorbing layer 32 with a thickness of 100 μm; (4) adopt nano conductive copper paste to prepare the heat absorbing layer in step (3) A layer of copper mesh is printed on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com