A fusion reactor tungsten divertor structure based on high temperature molten salt cooling

A high-temperature molten salt and fusion reactor technology, applied in the field of divertors, can solve the problems of difficult to further improve heat carrying capacity, poor helium cooling capacity and heat carrying capacity, poor engineering feasibility, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

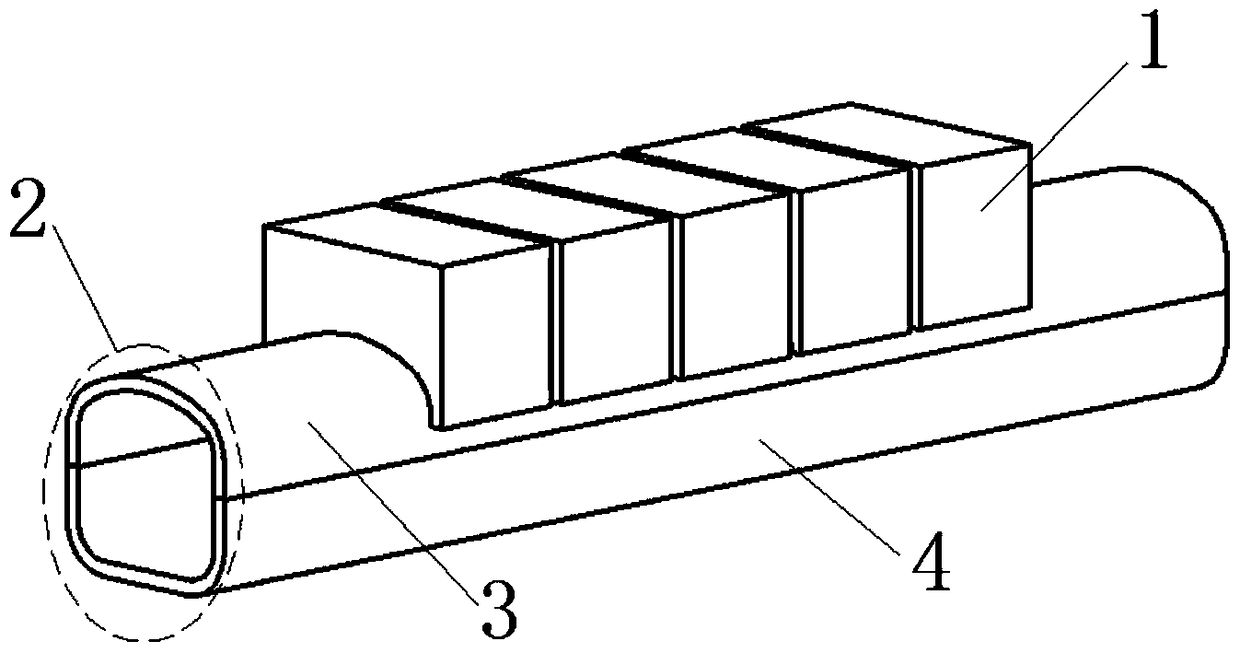

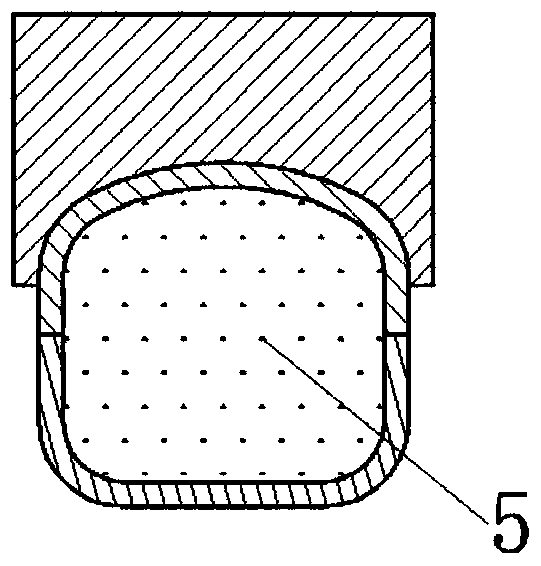

[0017] as attached figure 1 and 2 As shown, a fusion reactor tungsten divertor structure design based on high-temperature molten salt cooling includes a tungsten facing plasma material 1 and a tungsten-lanthanum alloy heat sink 2, and the tungsten-lanthanum alloy heat sink 2 includes a tungsten-lanthanum alloy heat sink-3 And the tungsten-lanthanum alloy heat sink 2 4, the tungsten-lanthanum alloy heat sink 1 3 is a half pipe with a C-shaped cross section, and the tungsten-lanthanum alloy heat sink 2 4 is a half pipe with a semi-rectangular cross-section with rounded corners. The tungsten facing plasma material 1 is connected to the tungsten-lanthanum alloy heat sink-3 by high-temperature vacuum brazing in the form of multiple small pieces, and then the tungsten-lanthanum alloy heat sink-3 is connected to the tungsten-lanthanum alloy by high-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com