A lignite drying waste heat and water recovery system

A technology of water recovery and waste heat, applied in lighting and heating equipment, indirect carbon dioxide emission reduction, combustion methods, etc., can solve the problems of unreasonable utilization, energy waste, heat loss of circulating water, etc., and achieve the effect of improving the economy of power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

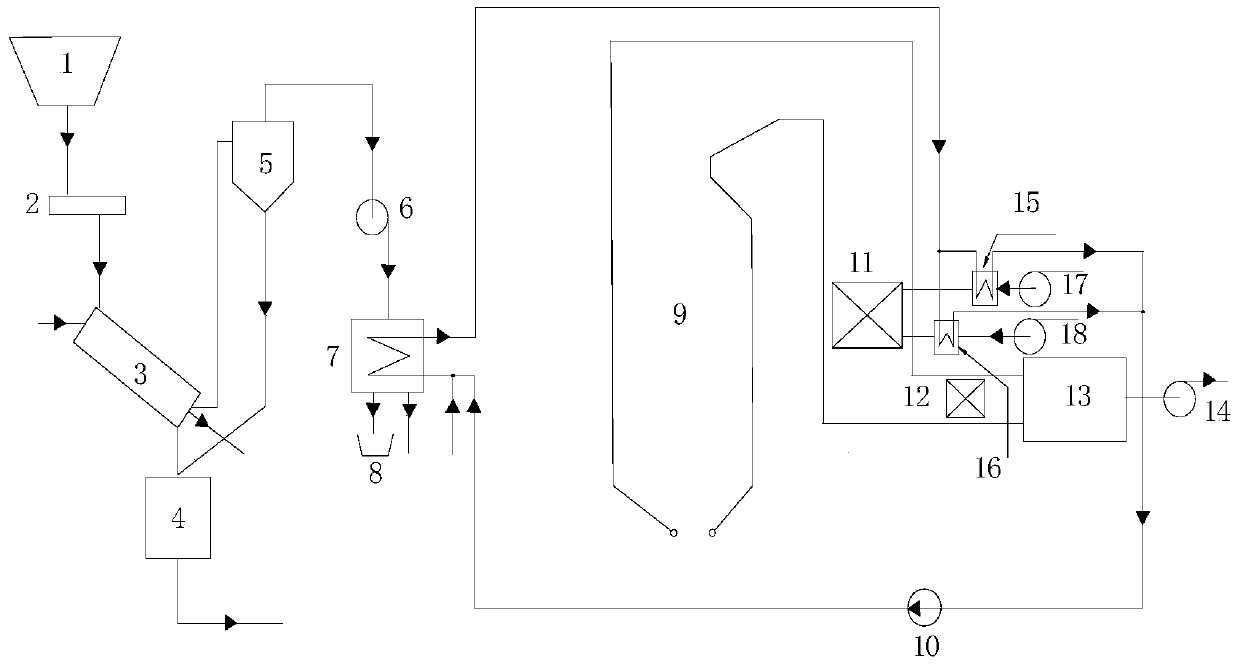

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] see figure 1 , a kind of lignite drying waste heat and water recovery system of the present invention, its technical key lies in the following points:

[0023] 1) The present invention is mainly composed of a coal bunker 1, a coal feeder 2, a steam pipe rotary lignite dryer 3, a bag filter 5, an exhaust fan 6, and a drying lignite production system composed of a coal mill 4 and a boiler 9. lignite pulverized coal preparation and use system, condensing heat exchanger 7, circulating cooling water pump 10, primary air heater 15, secondary air heater 16, primary air blower 17, air blower 18, etc. And air preheater 11, low pressure economizer 12, electrostatic precipitator 13, induced draft fan 14 and other boiler auxiliary equipment.

[0024] 2) In the present invention, the coal bunker 1 is used to supply coal for the coal feeder 2, the outlet of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com