Method for improving reliability of SONOS (Semiconductor-Oxide-Nitride-Oxide-Semiconductor) flash memory instrument

A flash memory device, reliability technology, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve problems such as erasing and writing window shrinkage, affecting reliability performance, etc., to achieve easy integration and improve reliability performance , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

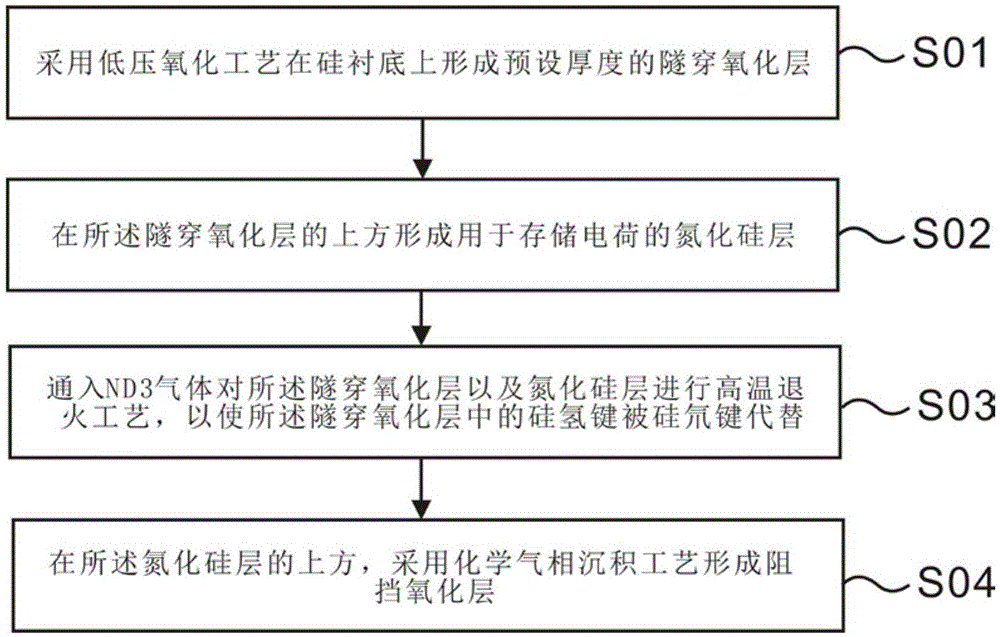

[0035] Such as figure 1 As shown, the present invention provides a kind of method that improves SONOS flash memory device reliability, comprises the following steps:

[0036] Step S01, please refer to Figure 3a , forming a tunnel oxide layer 2 with a preset thickness on the silicon substrate 1 by using a low pressure oxidation process.

[0037] Specifically, in this step, it is preferable to use in-situ oxygen atom oxidation equipment to prepare the tunneling oxide layer 2, and the process parameters for preparing the tunneling oxide layer 2 when the in-situ oxygen atom oxidation equipment is: the pressure is 500mtorr to 100torr, and the temperature is 800°C to 1200C, the time is 30s~10min, the ratio of hydrogen to oxygen is 2:1~1:3.

[0038] Step S02, please refer to Figure 3b A high temperature and low pressure chemical vapor deposition process forms a silicon nitride layer 3 for storing charges on the tunnel oxide layer 2 .

[0039] Step S03, please refer to Figure ...

Embodiment 2

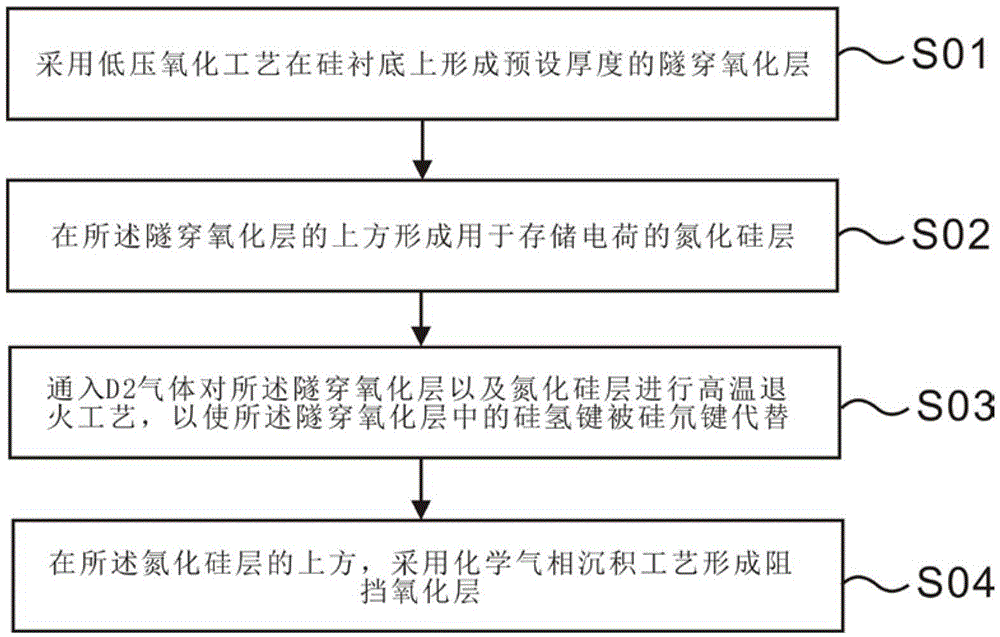

[0044] Such as figure 2 As shown, the present invention also provides a method for improving the reliability of the SONOS flash memory device, comprising the following steps:

[0045] Step S01, please refer to Figure 3a , forming a tunnel oxide layer 2 with a preset thickness on the silicon substrate 1 by using a low pressure oxidation process.

[0046] Step S02, please refer to Figure 3b A silicon nitride layer 3 for storing charges is formed on the tunnel oxide layer 2 by using a high temperature and low pressure chemical vapor deposition process.

[0047] Step S03, please refer to Figure 3c , into D 2 The gas performs a high-temperature annealing process on the tunnel oxide layer 2 and the silicon nitride layer 3, so that the silicon-hydrogen bonds in the tunnel oxide layer are replaced by silicon-deuterium bonds.

[0048] In this step, a high-temperature pre-annealing process is first performed on the tunneling oxide layer 2 and the silicon nitride layer 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com