Porous material made of Chinese herbal medicine extracted residues and application of porous material

A technology of porous materials and Chinese herbal medicines, applied in the fields of application, tobacco, food science, etc., can solve the problems of affecting the taste, drying of cigarette smoke, etc., and achieve the effects of convenient production, sufficient sources, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

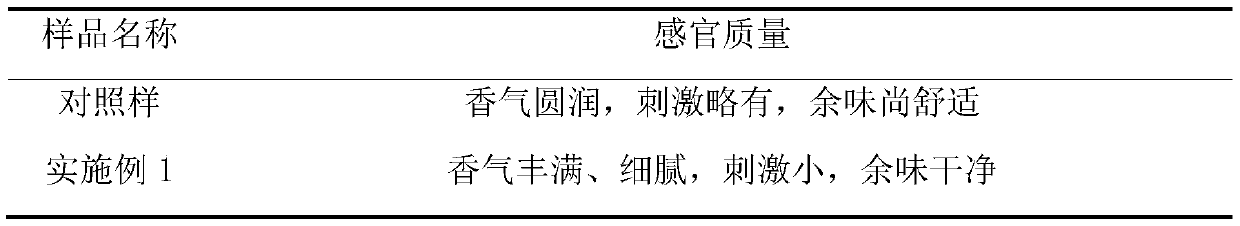

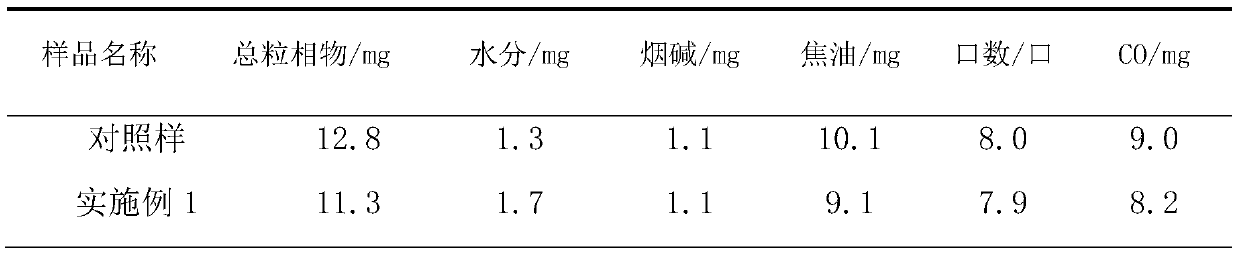

Embodiment 1

[0022] The residue after the extraction of the Chinese herbal medicine described in this example is extracted from dendrobium, filtered, and microwaved at a microwave power of 350W for 15 minutes, then the microwave-treated material is dried at 50°C, crushed and sieved A 20-mesh powder was obtained.

[0023] The preparation method of the residue porous material after Chinese herbal medicine extraction of the present invention specifically comprises the following steps: mixing the 20-mesh Dendrobium extract residue powder with the NaOH solution with a concentration of 5% in a ratio of 1:5 by mass ratio, and heating the mixture at 30° C. , 100r / min condition for 5h, filter, wash with distilled water until the pH value is neutral, and dry at 50°C until constant weight. Then it was fully mixed with a 5mol / L phosphoric acid solution at a mass ratio of 1:10, heated in microwave for 20min, then filtered and washed with distilled water to remove the phosphoric acid solution until the ...

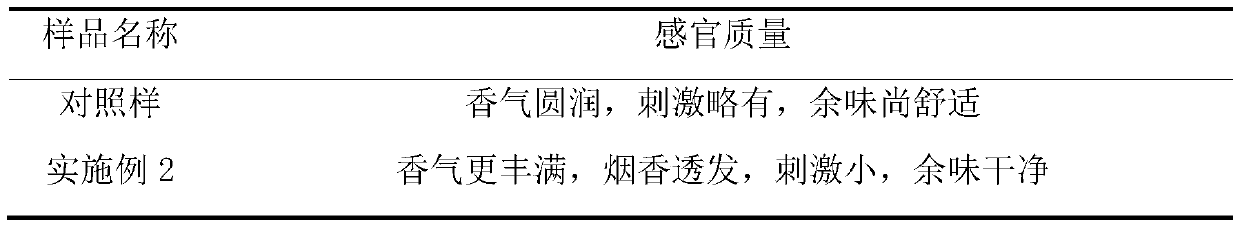

Embodiment 2

[0032] The residue after the extraction of the Chinese herbal medicine described in this example is filtered with Radix Ophiopogon japonicus as the raw material after extraction, microwave treatment at 500W microwave power for 10min, and then the microwave-treated material is dried at 60°C, crushed and sieved A 40-mesh powder was obtained.

[0033] The preparation method of the residue porous material after Chinese herbal medicine extraction of the present invention specifically comprises the following steps: mixing the 40-mesh Ophiopogon japonicus extract residue powder with the NaOH solution with a concentration of 10% in a mass ratio of 1:7, ℃, 110r / min conditions for 4 hours, filtered, washed with distilled water until the pH value is neutral, and dried at 60 ℃ to constant weight. Then it was fully mixed with 4mol / L phosphoric acid solution at a mass ratio of 1:12, and heated in microwave for 25min, then filtered and washed with distilled water to remove the phosphoric aci...

Embodiment 3

[0042] The residue after the extraction of the Chinese herbal medicine described in this example is extracted with Codonopsis pilosula as raw material, and the remaining residue is filtered, microwaved at a microwave power of 700W for 5 minutes, and then the microwave-treated material is dried at 70°C, crushed and sieved A 60-mesh powder was obtained.

[0043] The preparation method of the residue porous material after extraction of Chinese herbal medicine specifically includes the following steps: mixing 60-mesh Codonopsis Codonopsis extract residue powder with a mass ratio of 1:10 and a NaOH solution with a concentration of 15% at 50° C. , 120r / min condition for 3h, filter, wash with distilled water until the pH value is neutral, and dry at 70°C until constant weight. Then it was fully mixed with 2mol / L phosphoric acid solution at a mass ratio of 1:13, and heated in microwave for 30min, then filtered and washed with distilled water to remove the phosphoric acid solution unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com