Gel thin film array capacitor sensor and method for measuring total teeth dynamic occluding

A capacitive sensor, array technology, applied in the direction of sensor, testing muscle strength, diagnostic recording/measurement, etc., can solve the problems of large impact of bite force measurement, difficult bite force change trend, difficult disinfection, etc., to avoid measurement accuracy. effect, good biocompatibility, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

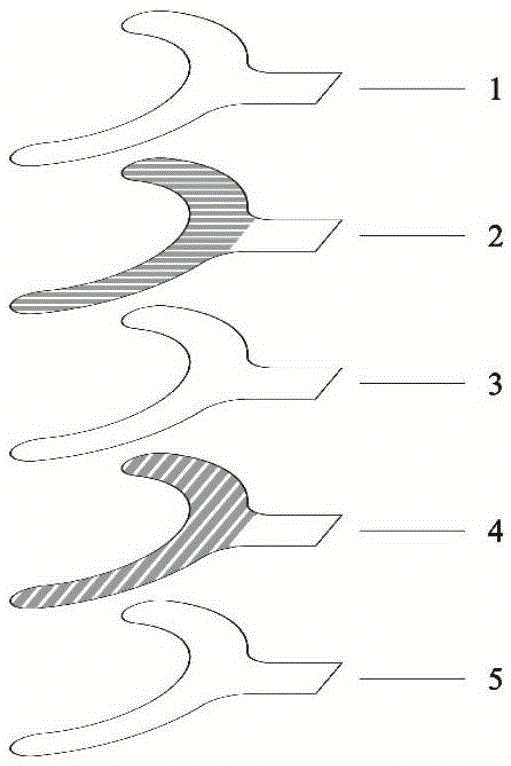

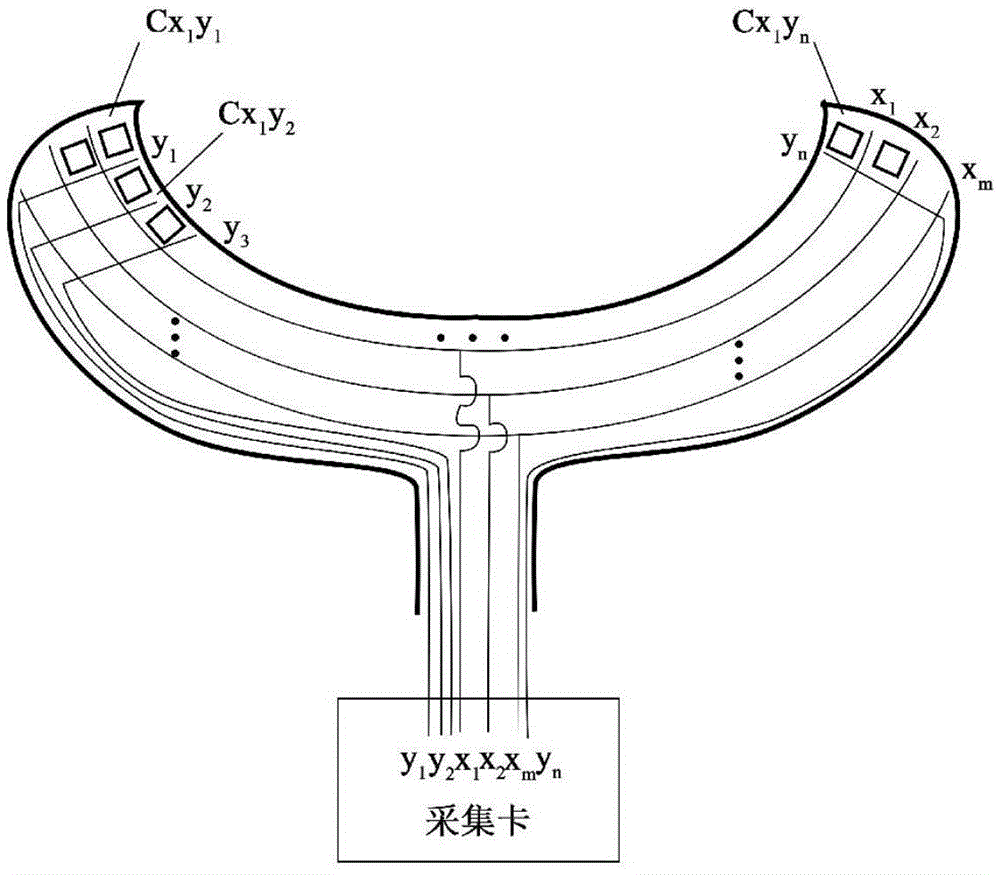

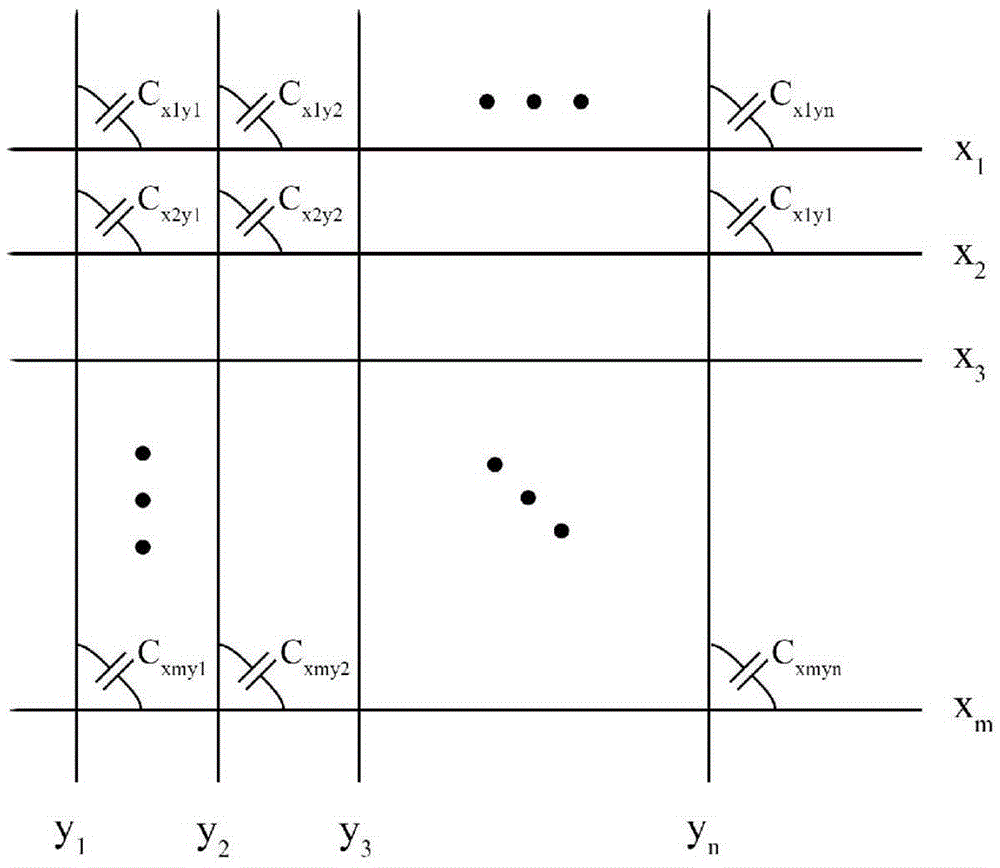

[0018] like figure 1 As shown, the gel film array capacitive sensor for measuring the dynamic engagement of the whole dentition in the present invention includes an insulating medium 3, which is U-shaped and a rectangular parallelepiped with a preset length protrudes outward at the middle of the arc to facilitate the lead-out, insulation The upper layer of the medium 3 is evenly bonded with the upper ion gel 2, and the ion gel in the upper ion gel 2 is distributed in rows, and the lower layer of the insulating medium 3 is evenly bonded with the lower ion gel 4, and the ion gel in the lower ion gel 4 The gels are distributed in columns, the upper surface of the upper ion gel 2 is pasted with the upper insulating medium 1, and the lower surface of the lower ion gel 4 is pasted with the lower insulating medium 5; the upper ion gel 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com