Improved peelable nail polish and preparation method thereof

A technology of nail polish and methyl phenyl, which is applied to improved peelable nail polish and its preparation, in the field of nail polish, can solve the problems of inconvenient production and use of the nail polish, and achieves good peelability, Reduced interaction, good peelability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

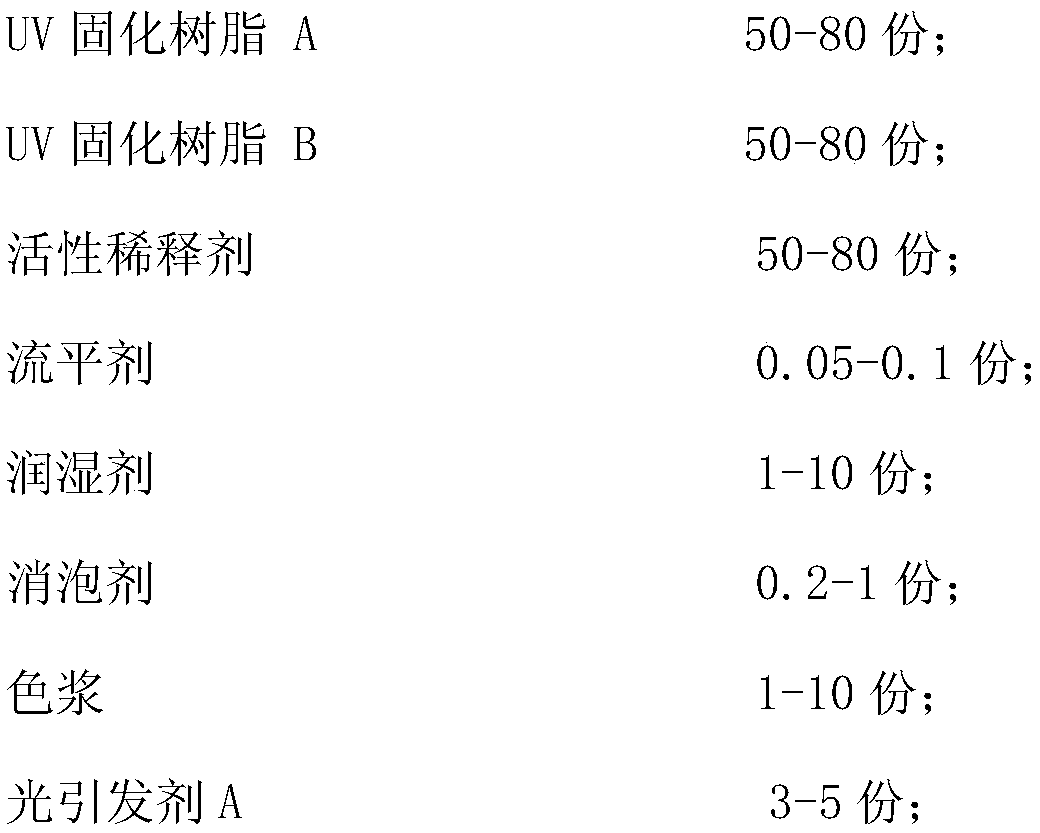

[0055] An improved peelable nail polish, calculated in parts by weight, its raw material composition and content are as follows:

[0056]

[0057] Wherein said UV curable resin A is calculated in parts by weight, and its composition and content are as follows:

[0058]

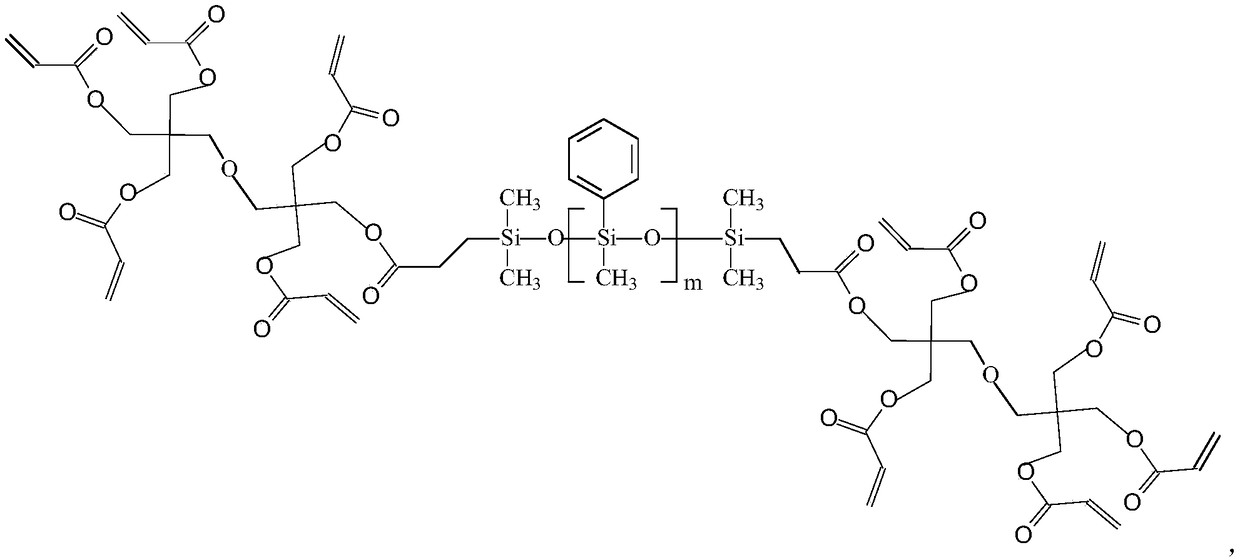

[0059] Described UV curing resin A is prepared as follows:

[0060] Add the above-mentioned 20 parts of methylphenyl hydrogen-containing silicone oil and 10 parts of dipentaerythritol hexaacrylate into a 500ml three-necked flask, then add 0.005 parts of polymerization inhibitor, pass in protective gas, stir and heat, and raise the temperature to 60°C. Add 0.03 part of catalyst, keep stirring for 3 hours, stop heating, wait until the temperature of the flask drops to room temperature, and obtain UV curable resin A.

[0061] The leveling agent is Tego Glide 410;

[0062] Described wetting agent is NP-100 of U.S. Dow Company;

[0063] The defoamer is a mixture of German BYK-035 and BYK-037 in a mass rati...

Embodiment 2

[0073] An improved peelable nail polish, calculated in parts by weight, its raw material composition and content are as follows:

[0074]

[0075]

[0076] Wherein said UV curable resin A is calculated in parts by weight, and its composition and content are as follows:

[0077]

[0078] Described UV curing resin A is prepared as follows:

[0079] Add 60 parts of methylphenyl hydrogen-containing silicone oil and 20 parts of dipentaerythritol hexaacrylate into a 500ml three-necked flask, then add 0.01 part of polymerization inhibitor, pass in protective gas, stir and heat, raise the temperature to 80°C, add 0.05 part of catalyst, keep the temperature under stirring for 5 hours, stop heating, and wait for the temperature of the flask to drop to room temperature to obtain UV curable resin A.

[0080] The leveling agent is a mixture of German BYK-345 and BYK-346 in a mass ratio of 1:1;

[0081] The wetting agent is German BYK 333;

[0082] The defoamer is a mixture of G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com