Formula and preparation technology of submucosal injecting material for endoscope

A formulation and mucosal technology, which is applied in the fields of pharmaceutical formulation, medical science, surgery, etc., can solve the problems affecting the application of sodium hyaluronate and the inability to inject sodium hyaluronate, so as to achieve good injectability, avoid secondary pollution, and good The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

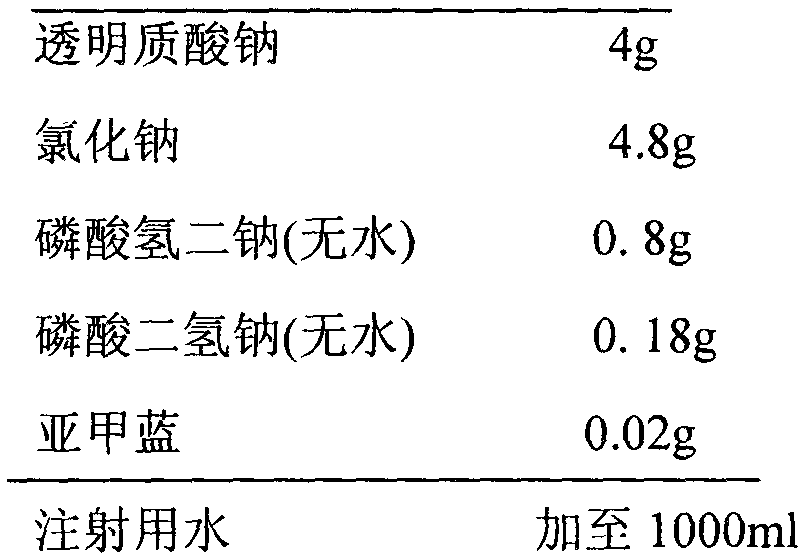

[0032] formula:

[0033]

[0034] Preparation Process:

[0035] Take an appropriate amount of water for injection, pour it into a reaction vessel with a stirrer, start stirring, slowly add sodium chloride, heat up to about 30°C, stir until completely dissolved; add sodium hyaluronate, heat up to about 40°C, and stir for 20 minutes ; Add disodium hydrogen phosphate (anhydrous) and sodium dihydrogen phosphate (anhydrous), and stir for 10 minutes; take the material liquid, measure the pH value; add appropriate amount of disodium hydrogen phosphate (anhydrous) and sodium dihydrogen phosphate (anhydrous ), adjust the pH value to about 7.5, add methylene blue, stir for 5 minutes, add water for injection to the full amount, and constant volume. Keep warm for 20 minutes. Filter the liquid through a 0.45 μm microporous membrane to the filling liquid storage tank. Take the liquid to measure the pH value, check the clarity, visible foreign matter, insoluble particles, etc. After p...

Embodiment 2

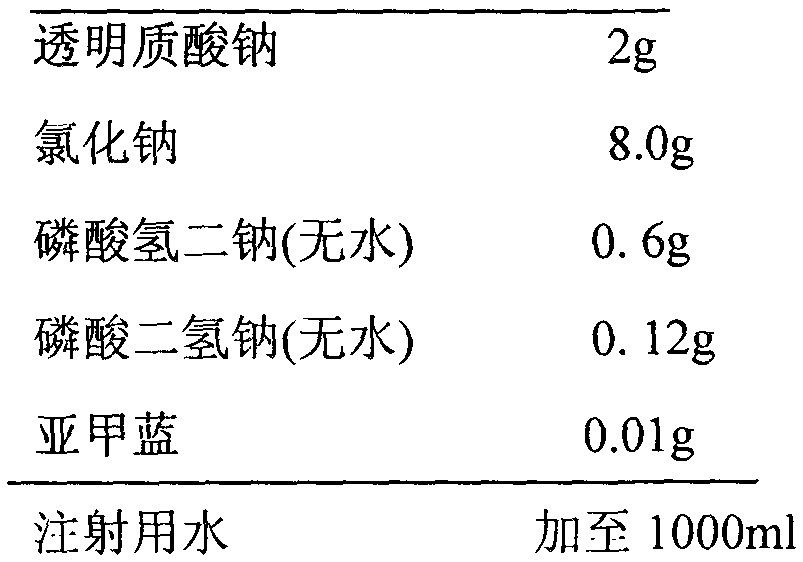

[0037] formula:

[0038]

[0039] Preparation Process:

[0040] Take an appropriate amount of water for injection, pour it into a reaction vessel with a stirrer, start stirring, slowly add sodium chloride, heat up to about 30°C, stir until completely dissolved; add sodium hyaluronate, heat up to about 40°C, and stir for 20 minutes ; Add disodium hydrogen phosphate (anhydrous) and sodium dihydrogen phosphate (anhydrous), and stir for 10 minutes; take the material liquid, measure the pH value; add appropriate amount of disodium hydrogen phosphate (anhydrous) and sodium dihydrogen phosphate (anhydrous ), adjust the pH value to about 7.5, add methylene blue, stir for 5 minutes, add water for injection to the full amount, and constant volume. Keep warm for 20 minutes. Filter the liquid through a 0.45 μm microporous membrane to the filling liquid storage tank. Take the liquid to measure the pH value, check the clarity, visible foreign matter, insoluble particles, etc. After p...

Embodiment 3

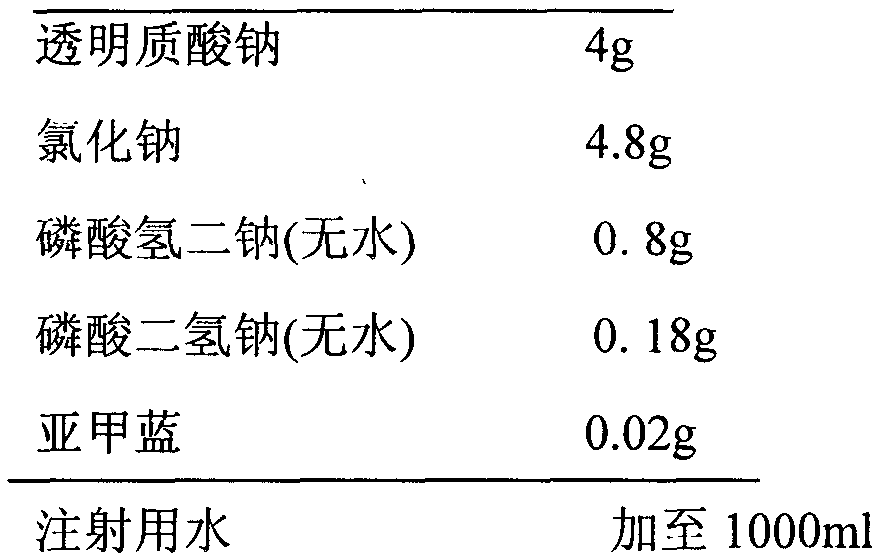

[0042] formula:

[0043]

[0044]

[0045] Preparation Process:

[0046] Take an appropriate amount of water for injection, pour it into a reaction vessel with a stirrer, start stirring, slowly add sodium chloride, heat up to about 30°C, stir until completely dissolved; add sodium hyaluronate, heat up to about 40°C, and stir for 20 minutes ; Add disodium hydrogen phosphate (anhydrous) and sodium dihydrogen phosphate (anhydrous), and stir for 10 minutes; take the material liquid, measure the pH value; add appropriate amount of disodium hydrogen phosphate (anhydrous) and sodium dihydrogen phosphate (anhydrous ), adjust the pH value to about 7.5, add methylene blue, stir for 5 minutes, add water for injection to the full amount, and constant volume. Keep warm for 20 minutes. Filter the liquid through a 0.45 μm microporous membrane to the filling liquid storage tank. Take the liquid to measure the pH value, check the clarity, visible foreign matter, insoluble particles, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com