A flat-plate falling-film freeze-concentrator and its freeze-concentrate method

A freeze-concentration and falling-film technology, applied in heat exchange cooling crystallization, solution crystallization, etc., can solve problems such as ice crystal solute entrainment, and achieve the effects of less active ingredient loss, convenient operation, and less solute

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

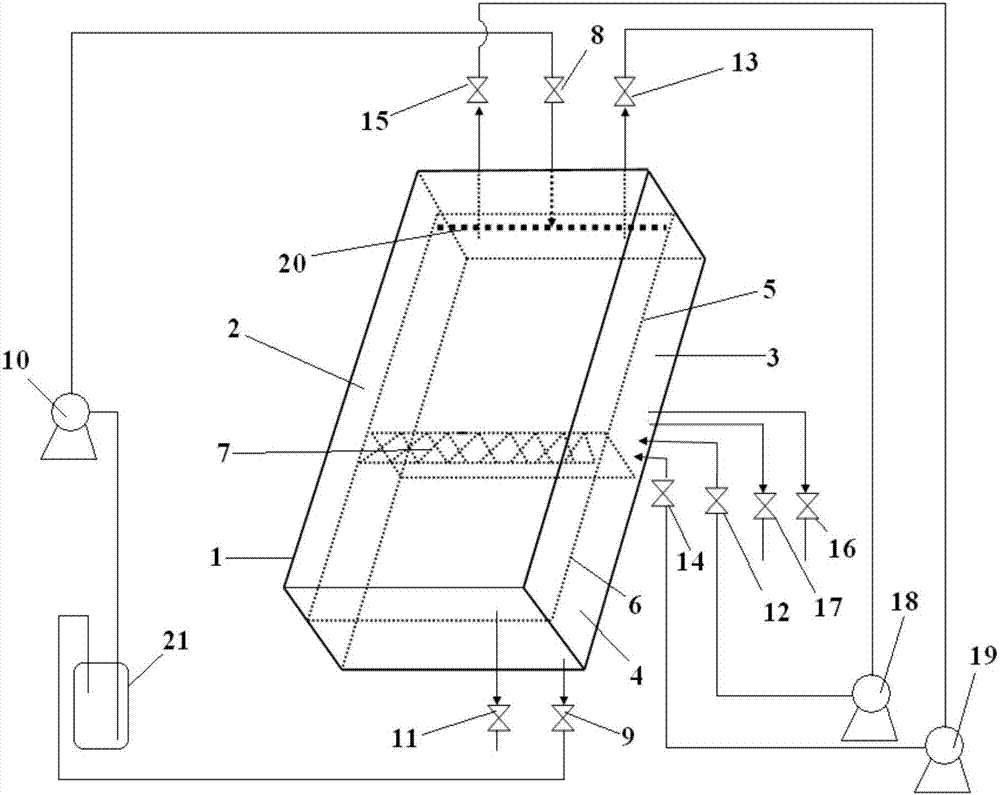

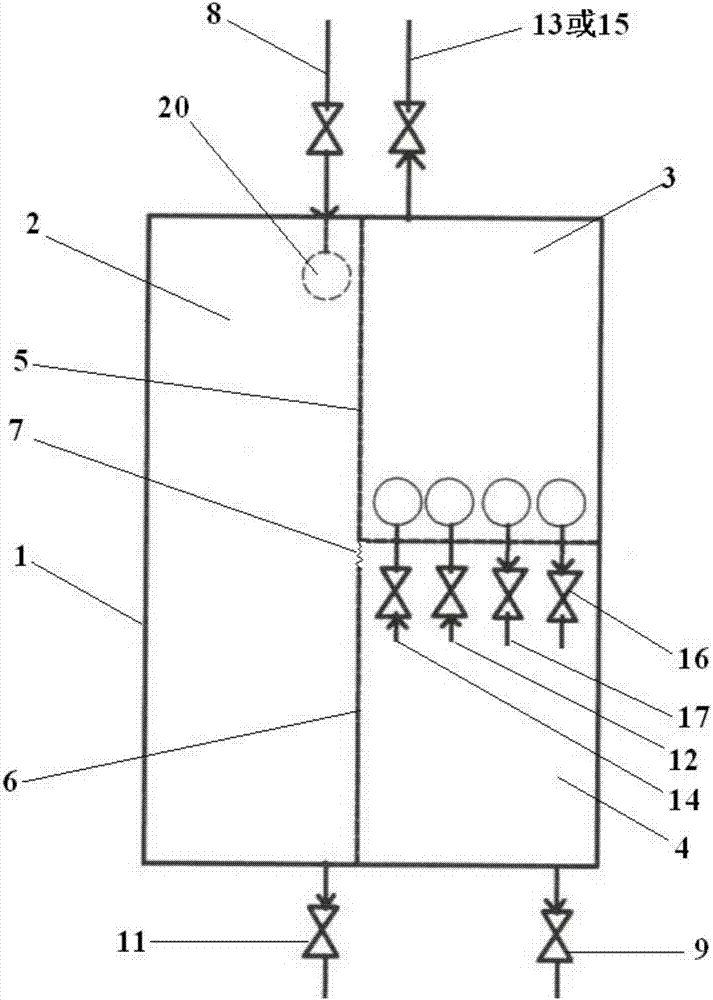

[0032] Comply with the above technical solutions, such as figure 1 with figure 2 As shown, the present embodiment provides a flat-plate falling film freeze concentrator, including a housing 1, and the housing 1 is divided into a falling film freezing chamber 2, a temperature control chamber 3 and a concentrated liquid through a heat conduction partition The collection chamber 4 and the falling film freezing chamber 2 are arranged on the upper layer in the shell 1, and the temperature control chamber 3 and the concentrate collection chamber 4 are arranged side by side on the lower layer in the shell 1;

[0033] The thermally conductive partition between the temperature control chamber 3 and the falling film freezing chamber 2 is a falling film freezing plate 5, and the thermally conductive partition between the concentrated liquid collection chamber 4 and the falling film freezing chamber 2 is an ice water collecting plate 6, One end near the falling film icing plate 5 on the...

Embodiment 2

[0039] The present embodiment provides a kind of flat-plate falling-film freeze-concentration method, the method adopts the flat-plate falling-film freeze-concentrator as described in embodiment 1, specifically comprises the following steps:

[0040] Step 1, place the housing 1 obliquely so that the falling film icing plate 5 and the ice water collecting plate 6 form an inclined surface and the falling film icing plate 5 is on half of the inclined surface;

[0041] Step 2, turn on the brine pump 18, keep the brine circulating in the temperature control chamber 3, turn on the solution pump 10, so that the solution to be concentrated is sprinkled on the falling film icing plate 5, and a part of the solution freezes on the falling film A icing surface is formed on the plate 5, and the remaining solution enters the concentrated liquid collection chamber 4 through the solid-liquid separation network port 7, and the flow rate of the solution on the falling film icing plate 5 is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com