Controllable preparation method of Cu3SbS4 nanocrystalline material

A nanocrystalline material and temperature control technology, applied in the nanomaterials and nano fields, to achieve the effect of simple process, good reproducibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Cu 3 Sb 4 The controllable preparation method of nanocrystalline material comprises the following steps:

[0020] (1) Add 3mmol cuprous iodide and 1mmol antimony chloride to 10mL oleylamine, pass through argon protection gas, control the temperature at 100°C, and stir rapidly for 20 minutes to make cuprous iodide and antimony chloride Completely dissolve to obtain a complex solution of metal salt;

[0021] (2) Add 11mL, 1mol / L diphenylthiourea diphenyl ether solution to the above metal salt solution, heat to the set temperature of 180°C and react for 120 minutes;

[0022] (3) After the reaction, cool to room temperature, add a large amount of methanol to react the Cu 3 Sb 4 Nanocrystals are cleaned to obtain Cu 3 Sb 4 nanocrystalline material.

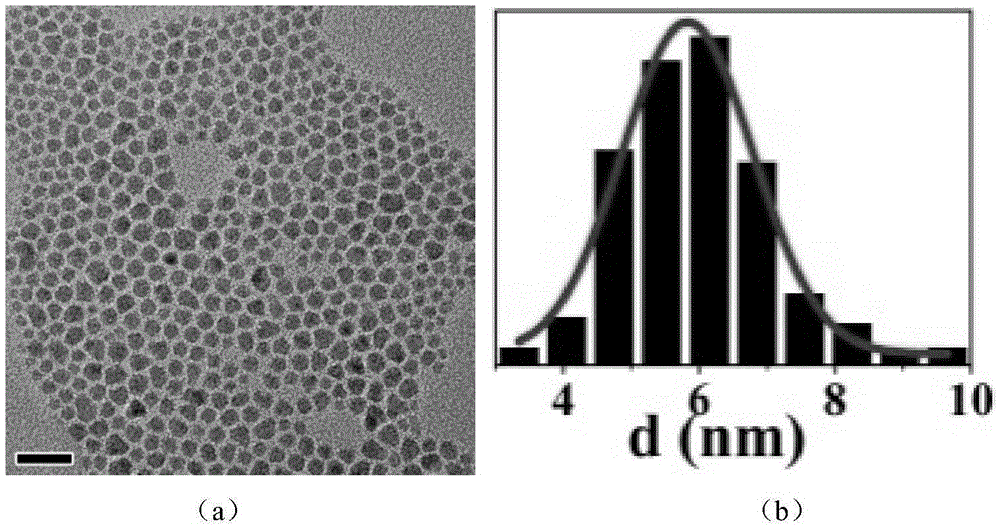

[0023] This embodiment prepares Cu 3 Sb 4 The particle size of the nanocrystalline material is 5.95nm, and its TEM image is shown in figure 2 in a.

Embodiment 2

[0025] Cu 3 Sb 4 The controllable preparation method of nanocrystalline material comprises the following steps:

[0026] (1) Add 3mmol cuprous iodide and 1mmol antimony chloride to 10mL oleylamine, pass through argon protection gas, control the temperature at 80°C, and stir rapidly for 10 minutes to make cuprous iodide and antimony chloride Completely dissolve to obtain a complex solution of metal salt;

[0027] (2) Add 9mL, 1mol / L diphenylthiourea diphenyl ether solution to the above metal salt solution, heat to the set temperature of 120°C and react for 60 minutes;

[0028] (3) After the reaction, cool to room temperature, add a large amount of methanol to react the Cu 3 Sb 4 Nanocrystals are cleaned to obtain Cu 3 Sb 4 nanocrystalline material.

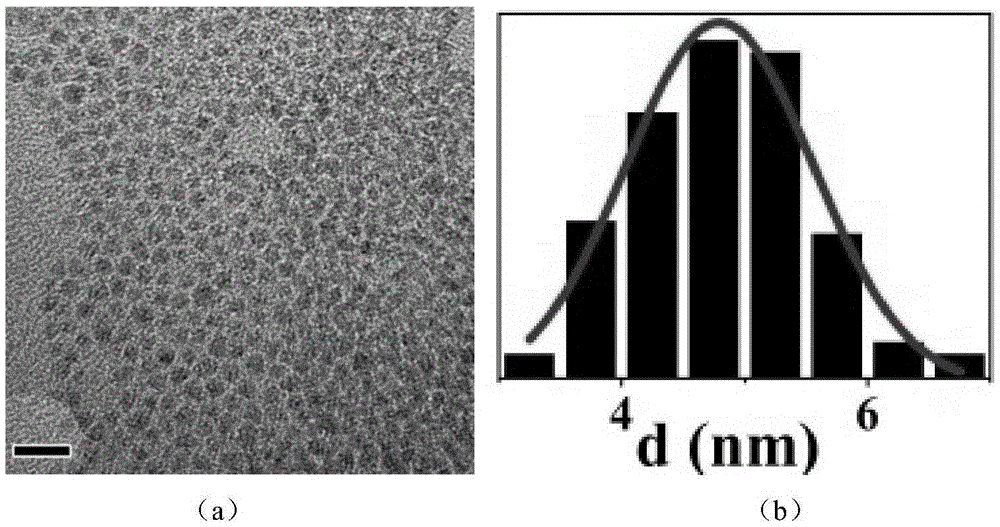

[0029] This embodiment prepares Cu 3 Sb 4 The particle size of the nanocrystalline material is 4.81nm, and its TEM image is shown in image 3 in a.

Embodiment 3

[0031] Cu 3 Sb 4 The controllable preparation method of nanocrystalline material comprises the following steps:

[0032] (1) Add 3mmol cuprous iodide and 1mmol antimony chloride to 10mL oleylamine, pass through argon protection gas, control the temperature at 60°C, and stir rapidly for 5 minutes to make cuprous iodide and antimony chloride Completely dissolve to obtain a complex solution of metal salt;

[0033] (2) Add 7mL, 1mol / L diphenylthiourea solution in diphenyl ether to the above metal salt solution, heat to the set temperature of 60°C and react for 1 minute;

[0034] (3) After the reaction, cool to room temperature, add a large amount of methanol to react the Cu 3 Sb 4 Nanocrystals are cleaned to obtain Cu 3 Sb 4 nanocrystalline material.

[0035] This embodiment prepares Cu 3 Sb 4 The particle size of the nanocrystalline material is 3.37nm, and its TEM image is shown in Figure 4 in a.

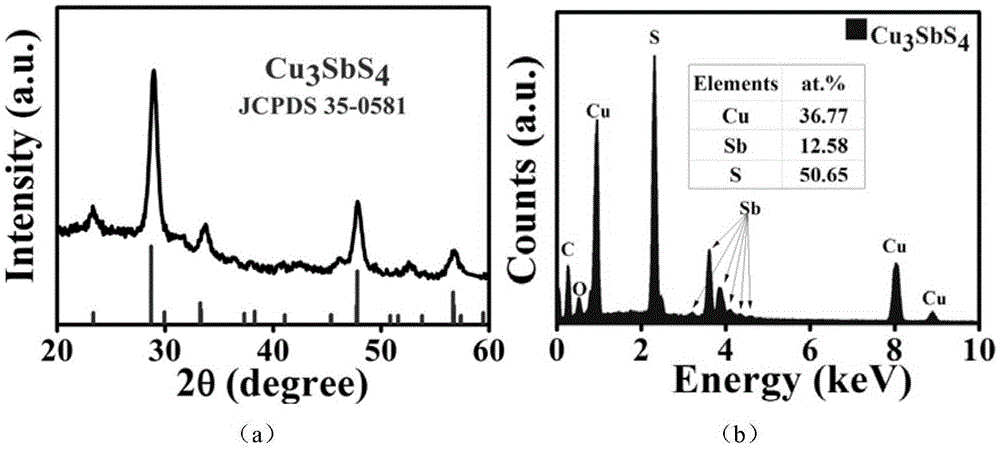

[0036] Cu prepared by the present invention 3 Sb 4 For the XRD spect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com